Enterprise AI for Control Valve Failure Prediction

A global oil and gas company with tens of thousands of employees in more than 70 countries delivers hundreds of thousands of barrels of oil per day to global markets. Each of its businesses is composed of multiple assets that include oil well basins, offshore platforms, refineries, pipelines and retail outlets. Each asset includes vast arrays of equipment that are orchestrated with the goal of maximizing the efficiency of oil production. At any point in time, any one of these components can fail—with potentially catastrophic results.

A single control valve failure in a refinery led to a $6 million loss due to maintenance costs and production losses. Losses of this kind can include the costs of both clean-up and asset downtime. With over 20,000 control valves in a single refinery and over 1 million in total, the company looked for proactive ways to discover and mitigate failures before they become catastrophic.

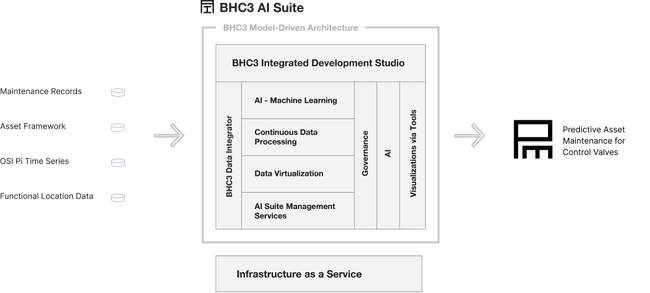

The company selected the BHC3™ AI Suite to develop and deploy a scalable predictive maintenance solution. Using this solution, they can now implement machine learning models at scale to predict the expected behavior of control valves within any downstream or upstream asset. The software flags any anomalous behavior to onsite engineers who can preemptively address failures.

About the Global Oil and Gas Company

- Hundreds of billions of dollars in annual revenue

- Millions of barrels of oil equivalent per day

- Tens of thousands of employees

- Operations are divided into different businesses within the upstream, midstream and downstream value chain

Building and deploying a predictive maintenance application

BakerHughesC3.ai (BHC3) and the oil & gas company first integrated five years of historical time-series data from one data source and two additional relational data sources, representing asset hierarchy and work order notifications, into a unified data model. Developers built machine learning pipelines using elastic net and random forest algorithms to allow end-users to bulk train models for hundreds of valves and individually tune single models.

With the application in production, instrumentation engineers went through the process of creating ML models designed to predict the expected output of a single sensor within an upstream/downstream asset. The sensor is represented as a prediction target (control valve) of interest.

On a daily basis, the BHC3 application receives relevant time series for every sensor within an asset. After data loading and normalization is complete, the application triggers predictions of the expected behavior of the prediction target. Alerting logic determines whether or not the actual value received from the source system is within the range of allowed deviation from the prediction. If it is not within acceptable tolerances, the application raises an alert for the instrumentation engineer to troubleshoot.

The Predictive Asset Maintenance for Control Valves application empowers this company’s end-user instrumentation engineers to configure, train and call predictions on ML models uniquely designed for each sensor. Users receive alerts raised by each model to proactively maintain the integrity of control valves at their largest refinery and lower the overall frequency of critical failure events.

Project Highlights

- Delivered an application for 160,000 sensors in a refinery to production within eight months from kick-off

- Ingested five years of historical time-series data from one data source and two additional relational data sources representing asset hierarchy and work order notifications

- Created a unified object model using the proprietary BHC3 model-driven architecture to represent the asset hierarchy, work order notifications, ML models, alert management and time series measurement and prediction data

- Built a rich multi-page user interface and application workflow that allows end-users to effectively manage the life cycle of thousands of individual machine learning models and to investigate anomalies and potential failures

Results

6

228,000

5

1,000+

Solution Architecture

Proven results in weeks, not years

Take the next step

Speak with an expert

Talk to one of our AI experts about what BHC3 products can do for the energy sector.

Request a demo

See the BHC3 AI Platform in action and learn more about our applications.

Schedule a briefing

Meet the BHC3 team in person and see what it's like to work with us.