Unlocking operational agility through an ongoing process

While technologies like asset health, condition monitoring, predictive analytics and anomaly detection can help organizations predict and react to changes in their operating environment, true operational agility relies on connecting systems and data through an ongoing process.

In a competitive and challenging economic climate, operational agility is not just a buzzword; it's a necessity. The ability to swiftly adapt and respond to changing conditions to maximize asset performance is critical to success. Yet, many organizations face a common challenge: siloed functions, systems, and data hinder agility and limit the potential for scalable continuous improvement.

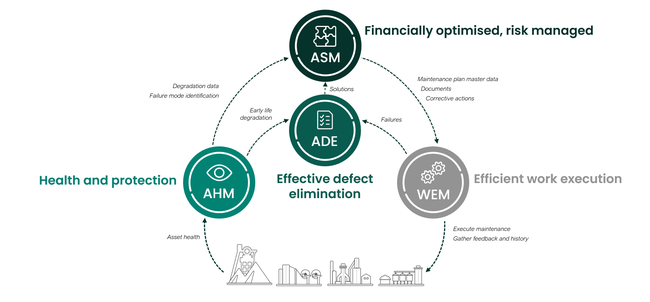

In asset management, this is reflected by a typical disconnect between asset strategy, asset health, defect elimination, and work management. This disconnect or lack of data integration between these domains creates inefficiencies and makes it difficult to get an enterprise-wide view of assets, their health, and work execution status. Without this view, it is difficult to quantify risks in real time and make decisions about how to prioritize and allocate resources. It is even more difficult to forward manage risks and drive continuous improvement across distributed assets.

An integrated approach to Asset Performance Management helps organizations overcome these challenges and it all starts with establishing a process that drives continuous alignment between asset strategies and changes in operating environments and priorities.

How process-driven APM increases agility

Traditional approaches to APM and even attempts at asset management digital transformation have been far too technology-centric and have failed to connect functions like asset strategy and asset health in a meaningful way.

A process-driven approach is different. It starts by connecting the siloed domains of APM in a way that allows organizations to consolidate, evolve, and better leverage their data across the enterprise. This ultimately helps organizations move from a reactive state where teams are always responding to unplanned failures to harmonized operations with predictable and financially optimized performance.

Benefits include:

- Dynamic and agile equipment maintenance and reliability with any operating context or asset changes reflected in asset strategies and monitoring applications

- Strategy changes driven through to work execution in the field with connection to work management process and EAM/CMMS application

- Predictable performance with increased ability to manage unplanned costs and mitigate risk

- Maximize production and efficiency through intelligent and risk-based reliability management

- Continuous improvement of performance through rationalization of current asset health and current asset maintenance plans.

How to make APM an ongoing process in your organization

Imagine a thread that runs through your entire operations, connecting asset strategy, asset health, defect elimination, and work management. The objective of this thread is to support the process which drives continuous improvement of assets while managing cost and risk. However, it must be tailored to your business, organizational structure, existing systems, and maturity.

At the foundation of this process is data, including consistent Failure Mode, Effects & Criticality Analysis (FMECA) data for assets of all criticality. With readily available FMECA libraries this data is essential as it helps to inform and drive action across the separate domains of APM. For example, if a condition monitoring alarm goes off, the content in the FMECA tells us what the impact of that failure will be, quantifies the risk, and informs the corrective action.

The development of the process should be used as a mechanism to rethink current ways of working and also assess the maturity of the processes and technologies driving your APM program. Only then, should you start to think about what’s needed in terms of a technical solution.

Download Making The Case for Integrated APM to learn more about how you can break down organizational silos and unlock operational agility.