Druck provides bespoke solution to address fuel monitoring in gas turbines

Customer Type: Gas turbine manufacturer

Industry: Power Generation

Application: Fuel monitoring for gas turbines

Solution: Druck's TERPS DPS8000 CANBus

The Druck team were approached by a subsidiary of a major technology manufacturer in the oil and gas industry, to provide a bespoke solution to address fuel monitoring in gas turbines.

Customer's challenge

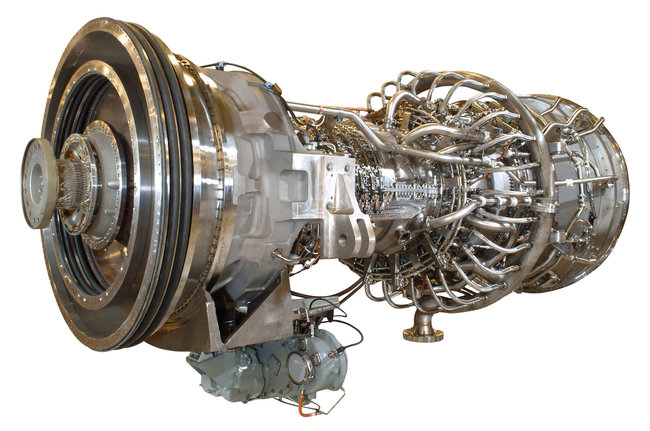

Commonly found in jet/aerospace engines, gas turbines are a critical part of many power facilities and are crucial in supplying a highly reliable and efficient power source. Keeping the gas turbines running requires much planning and maintenance in order to ensure continuous reliability and optimum performance. The parts involved in making the system operate and generate power are complex and work under very tight tolerances. The fuel control unit is a control system for the gas turbine engine and acts as an intermediary between the operator's controls and the fuel valve. The gas turbine engine is regulated by the amount of fuel supplied to the combustion chamber. The fuel control unit serves as a computer to determine the amount of fuel needed to deliver the power requested by the operator

Picture 1: Gas turbine

Pressure sensors installed in the fuel control unit are designed to keep track of how much fuel goes into the system. As the pressure sensors detect the information, the computer will analyse the data and make necessary changes to the timings and quantity of the fuel being injected into the engine. This allows the gas turbine engine to have optimal performance. Gas turbines are high temperature and high vibration environments. Druck’s customer required a sensor solution that could withstand this harsh operating environment in order to monitor the fuel in the gas turbines. The material and design were a key consideration, as sensor required needed to sense temperature and pressure changes at extreme temperatures for extended periods of time.

Druck’s solution and added value

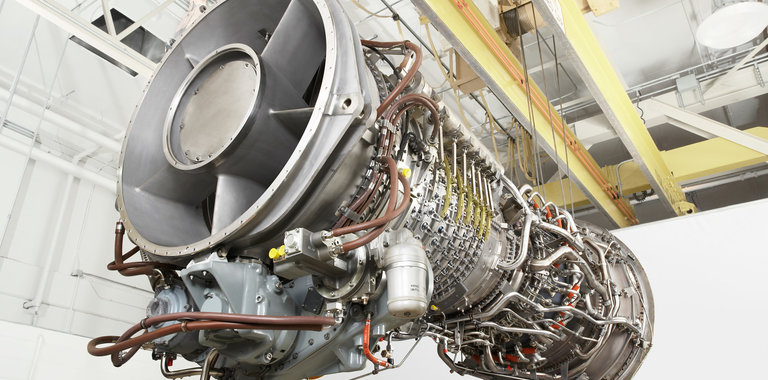

Druck’s customer upgraded to the DPS 8000 TERPS (Trench Etched Resonant Pressure Sensor) which uses resonant silicon sensing technology to provide the highest performance available from an industrial pressure sensor. The small size of Druck’s TERPS, coupled with its hazardous area certification and robust design, which enables operation at high temperatures allows the user to mount the pressure sensors directly onto the control valves.

Picture 2: Druck DPS 8000 TERPS

This provides the gas turbine operator with 3 main benefits:

- Reduced installation costs by reducing the pipework and removing an explosion-proof sensor enclosure.

- Decreasing the control system response time by removing the connecting pipework.

- The CANBus communication protocol supplied is both fast and timed, enabling it to be used in a time critical control application. It has the bonus of reducing installation and maintenance costs with a single bus wire around all the sensors in the system.

Druck’s TERPS units offer higher operating pressure ranges than many competitors’ products. This futureproofs the turbine’s control system design, as turbine manufacturers continue to develop turbines with a higher power output.