Standardisation in Subsea Oil & Gas

Customer Type: Subsea Christmas Tree Manufacturer (Oil Well)

Industry: Oil & Gas

Application: Pressure and temperature measurement

Solution: Presens Asterix HT

Our Subsea Team were approached by a major Subsea Oil and Gas tree manufacturer looking for standardised instrumentation. The Customer has manufacturing plants in several countries and supplies to all oil and gas operators.

The Subsea oil and gas industry faced a serious downturn following a fall in oil prices during 2015. Druck’s Customer faced the challenge of reduced demand from Oil and Gas operators for their products and a market-wide drive for cost reduction. Despite the drive for cost reduction, there was no willingness amongst end-users to reduce their technical requirements for the products that Druck’s customer supplies. Druck’s Customer needed to reduce costs and lead-time, but also maintain an offering supporting the stringent project-specific requirements of the end user. Druck’s Customer chose to develop a supplier-based solution for a standard configurable subsea Christmas-tree.

In a market with reduced demand, it is a huge challenge to remain profitable for all participants in the Subsea supply chain. The downturn in the Subsea market (relative to the peak years of 2013 and 2014) has now lasted for several years and the market is not expected to recover to those levels within the medium term outlook. Rationalisation of the entire supply-chain was necessary to stabilise into a new market reality.

Our Subsea Team had already started the development of the our next generation subsea product during 2013, targeting cost-out and compliance to the Subsea industry standards. The product was later introduced in 2014.

Amid the industry downturn in the oil & gas market, time was spent refining the design into a generic platform which supports 80% of market demand, thus limiting product variations and allowing for a cost-effective supply-chain.

The core of the product is qualified to the highest-pressure rating (20kpsi) meaning that the high volume aspects of production of the product are platformed ensuring production efficiency and reduced costs, while the top-level configuration of the product can be customised based upon the customer’s project specific need.

The product is the Presens Asterix HT and these increasingly simplified configurations are now baselined on our customers’ trees. Stocking agreements have been implemented allowing us to build the product “cores” to stock, thus greatly reducing the final product lead-time.

The standardised product structure has greatly simplified our customers’ planning and buying processes.

The Presens Asterix HT is designed and qualified to a level allowing our customer to provide a standard tree, including instrumentation, to fit most subsea greenfield developments and brownfield tie-backs.

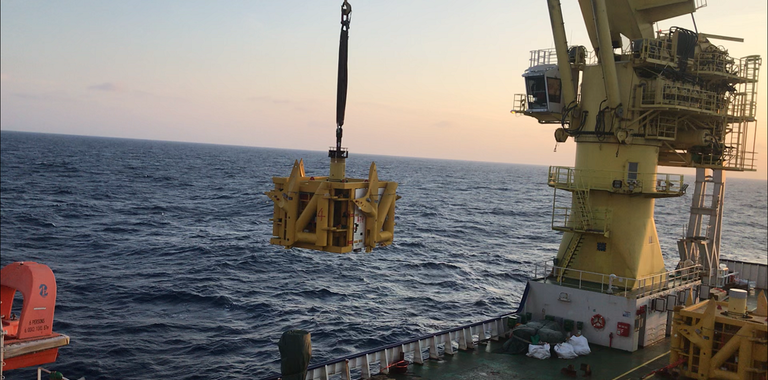

Picture 2: Presens Asterix HT

Our previous methodology allowed mass customisation which led to a reactive production process, meaning that the bespoke product was specified late in the execution of the Subsea tree assembly project due to the long lead time that was required. A standardised product and stocking agreement have greatly reduced risk around cost and lead-time and created considerable value for our customers and Oil and Gas operators.

Find out more about Druck on LinkedIn