Highlights

Highlights

Benefits

- Non-proprietary solvent

- No thermal and oxidative degradation

- High CO₂ delivery pressure

Features

- Simple chemistry

- Tolerant to oxygen

- High capture rate

Applications

- Power generation (e.g., waste-to-energy plants, biomass power plants, etc.)

- Industrial (e.g., cement plants, etc.)

- Oil and gas (e.g., SMRs, utility boilers, etc.)

Overview

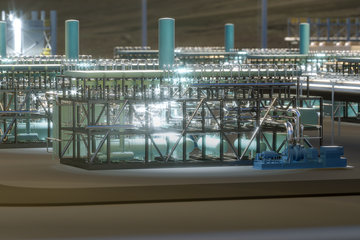

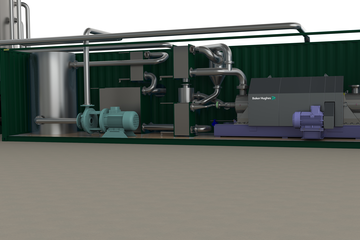

The chilled ammonia process (CAP) was developed to address the challenges of removing carbon dioxide from low-pressure flue gases generated by fossil-fuel-based power plants and industrial emissions points such as coal-fired power plants, waste-to-energy power plants, biomass power plants, cement plants, refineries, and petrochemical complexes.

CAP is a post-combustion carbon-capture process that uses a non-proprietary solvent formulation based on readily available ammonia. It has achieved technology readiness level 7 according to the H2020 definition. Thanks to its simple and stable chemistry, its solvent is not influenced by trace components (e.g., NOx, O2) or thermal and oxidative degradation. It's tolerant to oxygen, high temperatures, and flue gas impurities.

CAP was successfully demonstrated (TRL 7) at Technology Center Mongstad using flue gas streams with high (16% CO2) and low (3.6% CO2) CO2 concentrations.