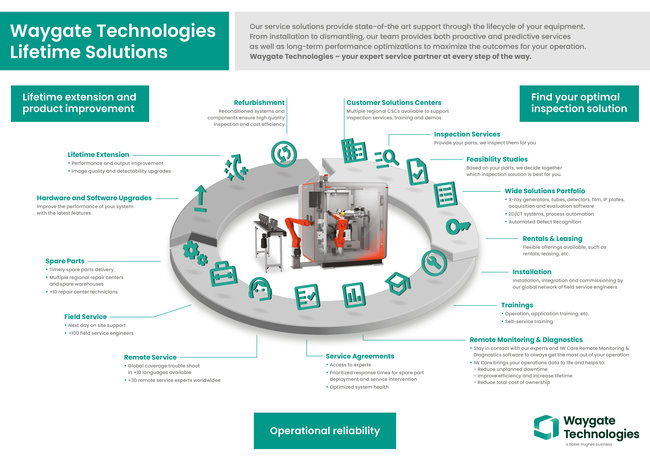

X 射线和 CT 系统的软件更新

通过我们的各种软件更新,充分发挥您的系统的性能! 在特定的时间点,更新可能是必要的,但通过对工业 CT 系统进行面向未来的改进,有助于您提高设备的性能、图像质量和生产率,从而确保设备创造更多利润。

巅峰系统性能由此开始

您是否正在使用 Waygate Technologies 的工业计算机断层扫描 (CT) 系统? 我们注重持续改进,不断开发新的软件功能,以提升您的工业 CT 扫描仪的性能和生产率。

抓住机会,了解此类新功能如何使您的特定应用受益,以及如何提升您的工业 X 射线系统的性能。

利用我们最新推出的功能增强技术来提升您的射线照相和 CT 扫描系统:免维护连接器的特点是在射线管和发生器两端均采用扁平连接器。 这一尖端创新技术旨在提供无可比拟的可靠性,它将彻底改变 Microfocus CT 的面貌,使其能够延长服务间隔,从而最大限度地减少维护干预需求并减少服务中断次数。 得益于该功能提供的极为可靠的连接,避免了长时间系统停机的困扰。 总拥有成本的大幅降低,进一步加强了该功能在效率和成本效益方面的支柱作用。 这项新功能受专利保护,凸显了其独特性,并使其成为全球放射成像和 CT 扫描系统领域的变革者。

-

提升稳定性和可靠性,尤其是在微聚焦 CT 应用场景中。

-

延长服务周期,减少技术服务人员介入,最大限度地缩短停机时间。

-

每台设备每年可多运行 5 天时间,同时可减少 33% 以上的停机成本,实现了运营资源的优化。

升级包有两种类型可供选择:

-

带有扁平和锥形连接器的芯棒和电缆,其将取代射线管和发生器之间的现有连接。

-

两侧均带有扁平连接器以及带有一个新发生器的芯棒和电缆,可替换射线管和发生器之间的现有连接以及发生器本身。

特点

加快较长零件的扫描速度,同时提升扫描质量

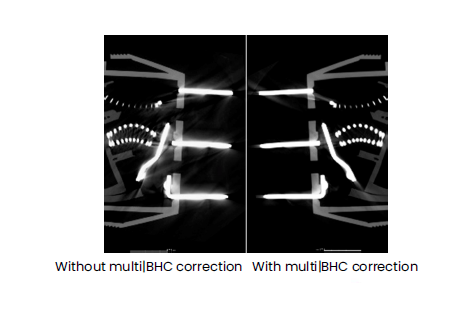

修正射束硬化伪影

轻松设置新的虚拟扫描轴,用于扫描未居中的 ROI

更准确地扫描较大的零件

用于吸收能力强的特殊自适应散射校正滤波器

升级选项:软件