Highlights

Highlights

Improve efficiency

Simplify and streamline management of distributed fiber-optic temperature-sensing, distributed strain-sensing, and distributed acoustics- sensing data.

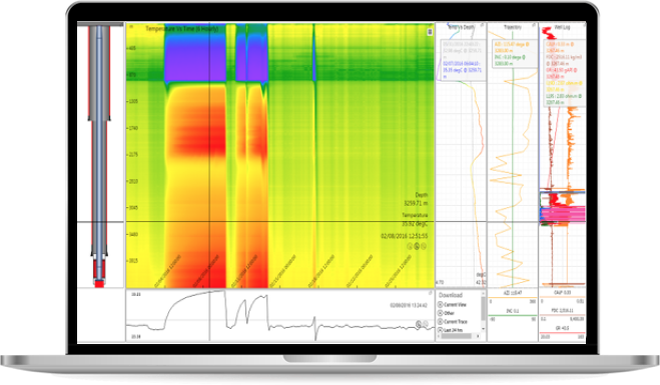

- View data in grid form, trend charts, or heat maps

- Configure alerts for key events or to prompt action

- Customize downhole analytics

Reduce costs

Seamlessly transmit, store, and visualize critical well data with a flexible, web-based domain-focused software-as-a-service solution.

- Reduce your workload

- Reduce operating costs

- Choose flexible deployment models

Enhance production

Leverage advanced visualizations to rapidly identify trends, diagnose downhole conditions, and improve recovery.

- Create integrated visualizations of key data types

- Track temperature, strain, and acoustic readings

- Combine DTS, DSS, and DAS data

Combining fiber-optic distributed sensing data with other surface and downhole information can generate the insights you need to make more informed operational decisions—and enhance production and recovery. But practices for managing this information are complex, costly, and time consuming, making it difficult to extract the full value of your data.

Our ProductionLink™ Optical Solutions service speeds up and simplifies the management of fiber-optic distributed sensing data. The flexible, web-based solution seamlessly transmits, stores, and visualizes distributed temperature-sensing (DTS), distributed strain-sensing (DSS), and distributed acoustics-sensing (DAS) data, enabling instant access and rapid analysis, at any time or location.

In addition, the software-as-a-service (SaaS) deployment model reduces your workload and costs, and eliminates excess hardware, software, and licenses.

An interactive, web-based dashboard tracks temperature, strain, and acoustic readings in each asset, across both time and depth. It also enables you to combine DTS, DSS, and DAS data with other surface and downhole information, including well logs, schematics, and trajectories. Through integrated visualizations of these different data types, you can rapidly identify trends, patterns, and anomalies to diagnose downhole conditions, enhance production, and improve overall recovery.

The use of production mark-up language standards simplifies the management and integration of well data so you can quickly and easily share your data, track metadata, and save multiple versions, without losing any raw data in the process.

You’ll also get instant access to complete data sets along the entire wellbore, thanks to the service’s ability to transmit and store high volumes of data in real time. In addition, its scalability means users can track the performance of multiple fields or a few select wells.