Overview

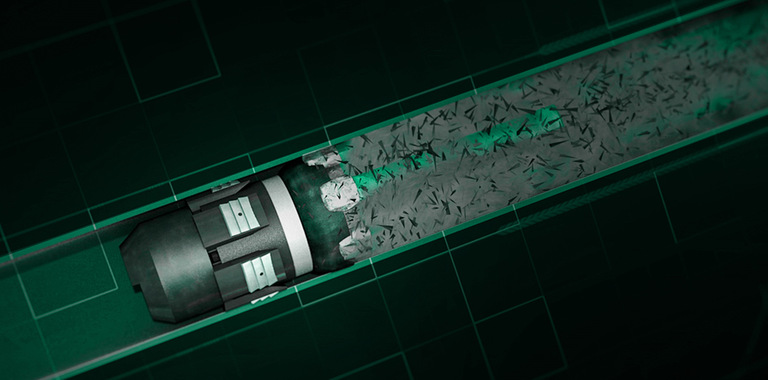

Frac plug milling services from Baker Hughes give you a full range of tools to effectively mill out every plug—from the toe to the heel of your lateral—and bring your well into production as soon as possible.

- Mill out your frac plugs—quickly and cost-effectively—with our proven bits and mills. Design advances such as our AMT section mills deliver longer milling runs in a single trip—letting you get your well into production faster than conventional milling tools.

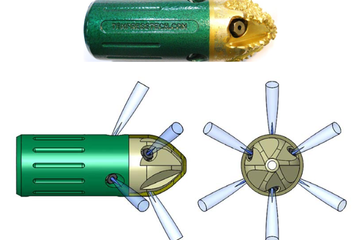

- Ensure effective removal of all your milled plug debris with our range of diverter subs. These subs completely remove all debris from your wellbore, assuring higher production rates and reduced risk of stuck coiled tubing downhole.

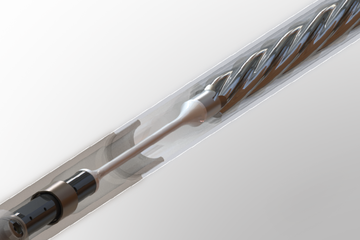

- Overcome the frictional forces that can limit the lateral reach of your tubing string with our extended-reach tools. Our tools generate water-hammer pressure pulses that effectively break frictional drag forces between the tubing and wellbore, which lets your coiled-tubing-deployed milling tools reach the farthest plug in your lateral.

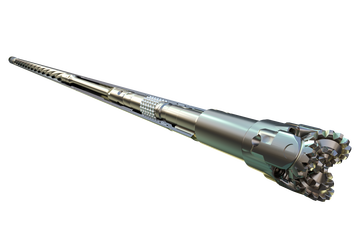

- Maximize the power delivered to your milling bits with our Navi-Drill™ series of positive displacement workover motors. With their modular components, durable designs, and advanced metallurgies, our workover motors ensure reliable and efficient power in your longest, hottest, and highest pressure wells.

Contact us to learn how our frac plug milling services can help maximize your well’s full production potential.