SureFLO downhole flowmetersOur SureFLO™ downhole flowmeters enable you to make informed decisions that will maximize your well’s productivity while reducing operating costs and minimizing risk. Take the guesswork out of your production profile with a SureFLO downhole flowmeter—backed by the world’s most trusted source for this technology.

SureFLO 298A quarter-century of experience as the market leader in downhole flowmeters means that you can count on the wellbore and reservoir data this device delivers. The SureFLO 298 flowmeter has a customized venturi design that can handle a variety of production rates and fluid properties. We ensure the right design is deployed for your application, so you get the most accurate data possible to improve operational efficiency. Applications include heavy oil and wet gas.

SureFLO 298EXEver wondered how a constriction in the well affects your productivity? The SureFLO 298EX fullbore downhole flowmeter brings you real-time production data without affecting your recovery potential. Its innovative design minimizes pressure loss associated with downhole tools, ensuring your well can produce with its natural lift. Intervention can be performed through the flowmeter without additional production downtime caused by well-intervention exercises. Conventional downhole flowmeters require two additional wireline runs: one to retrieve the wireline venturi sleeve and a second to set the venturi back in place after the intervention run. The SureFLO 298EX provides real-time data that enables you to determine whether the intervention has affected production in a desirable manner. The industry’s first fullbore-access downhole electronic flowmeter, the SureFLO 298EX provides unrestricted access to assure full production—and can achieve a high-accuracy measurement of 98%.

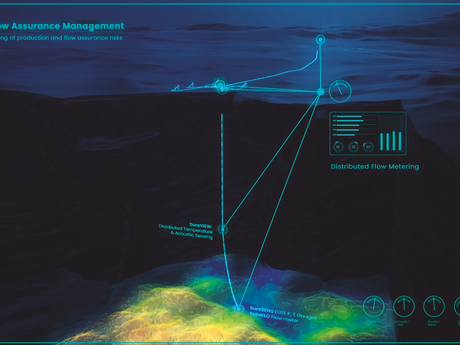

SureCONNECT downhole intelligent wet-mate systemThe SureCONNECT™ downhole intelligent wet-mate system enables monitoring and control along the entire well, for the life of the well. Real-time well-surveillance data are critical for making the decisions that will optimize production, reduce risks, and ultimately maximize returns. But historically, obtaining these data has been challenging due to the complexity of running and connecting lines over long distances downhole, and because of long-term reliability concerns in extreme environments. Operators are often blind to what is happening downhole, especially in the pay zone. The SureCONNECT downhole intelligent wet-mate system was developed to solve this ongoing issue. This modular system enables connection and re-connection of upper completion components to the lower completion with hydraulic, electric, and/or fiber-optic lines. Operators can now achieve real-time, interventionless monitoring and control across the entire wellbore of multi-trip completions—enabling data-driven decisions to optimize reservoir performance and proactively mitigate risks for the life of the well. The SureCONNECT system utilizes a downhole wet-mate connector that houses up to five channels and comes together to connect the upper and lower completions. Each channel supports two hydraulic lines, one electric line, or one six-fiber line. Using this modular approach, operators can choose the lines they want to include without customizing and designing a new system, driving reliability and consistency. For the first time, operators can achieve fiber-optic, real-time distributed temperature sensing (DTS) and distributed acoustic sensing (DAS) monitoring across the entire wellbore. The system is also compatible with other downhole technologies used to shut off zones and optimize production, creating standardization across intelligent-completion designs. The data provide a better understanding of the performance of natural fractures, complementing existing conventional well-surveillance data to drive better placement decisions in future field developments. The SureCONNECT system also eliminates the need to remove an operational lower completion during workover operations, significantly decreasing rig time, HSE risks, and equipment costs. Contact your local Baker Hughes representative to learn how the SureCONNECT system can help you achieve fullbore well monitoring and control for the life of your well. Applications

Features and benefits

|

Overview

Contactez un expert.

Votre demande a bien été envoyée.

Merci de votre intérêt. Un spécialiste vous contactera bientôt.