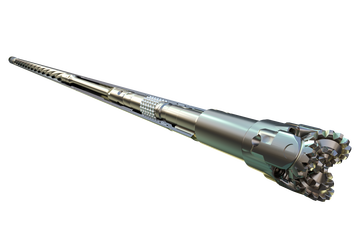

Workover motors from Baker Hughes offer proven reliability and performance in your milling, drilling, or cutting operations.

Our Navi-Drill™ series of positive displacement workover motors is designed on the operating principle of a progressing cavity pump. The motor’s rotor and the stator form a series of sealed cavities such that when fluid is pumped into the tool, the rotor will be driven in an eccentric, rotary motion relative to the stator. Allowing the fluid to pass while transmitting rotational power to the drive train and mill makes it ideal for use in your coiled tubing applications.

Workover motors for every application

Regardless of your intervention need, our workover motors have you covered.

- Select motors that cover a full range of milling operations with regard to tool size, bit speed, torque, and flow rate

- Choose from a range of motors that operate effectively with most types of fluids in a wide range of fluid weights and viscosities, including nitrogen, air, mist and foam

- Select from different elastomers for your motor, depending on the temperature, the type of motor, and the downhole environment

- Find special motor configurations that can reliably deliver outstanding performance in higher temperature environments

Design innovations for challenging environments

Navi-Drill motors are available in two main product designations.

The VIP™ 2.0 series delivers versatile increased performance, with design features that include:

- Power sections that operate in moderate to severe environments and incorporate different elastomers and lobe configurations to work efficiently in varying temperature and fluid combinations

- Transmission and bearing sections designed to withstand forces generated during normal coiled tubing milling and cutting operations

- Modular components that lower operating costs while enhancing the interchangeability of different power sections

Based on innovative equidistant power section technology, the Navi-Drill X-treme™ series motors are built for greater reliability and efficiency. Design innovations include:

- The power section’s contoured stator has 90% less rubber content compared to conventional positive displacement motors

- The thin, uniform layer of field-proven rubber compound allows for higher efficiency, lower friction, and less distortion

- The power section is more tolerant to higher temperatures, pressures, and fluid solids—all of which translate to improved reliability and significantly increased power output

- Different motor body types and specifications are available for special applications such as restricted riser heights; applications requiring reduced on-bottom milling times; and underbalanced well interventions using foam, nitrogen, or air.

Contact us to learn how workover motors from Baker Hughes can optimize your thru-tubing intervention operations.