Highlights

Highlights

Benefits

- Best-in-class (over 44%) simple-cycle efficiency in mechanical drive; 55,000 tons less CO₂ per year versus its main competitor

- Free power turbine for maximum operating flexibility

- Engine swap capability for minimum maintenance downtime

Features

- 44:1 pressure ratio; intercooled cycle reduces compressor work by 30%

- Free power turbine has a wide speed range (2,880 to 3,600 rpm)—so no gearbox needed in either 50/60 Hz applications

- DLE 2.1 technology (25 ppm NOx emissions)

Applications

- LNG

- Industrial

- Combined heat and power

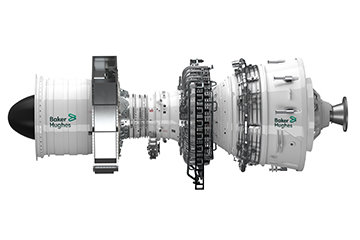

Overview

With more than 70 units working in power generation with over 800,000 combined operating hours, the LMS100PB+ gas turbine provides the highest simple-cycle efficiency in the world thanks to its unique intercooling technology.

Specification

Mechanical drive

ISO conditions (15°C, sea level, 60% relative humidity, zero inlet and exhaust pressure losses), with natural gas fuel. Efficiency and power in power generation configuration at generator terminals. Package dimensions exclude driven equipment.

Specification

Power generation (50/60 Hz)

ISO conditions (15°C, sea level, 60% relative humidity, zero inlet and exhaust pressure losses), with natural gas fuel. Efficiency and power in power generation configuration at generator terminals. Package dimensions include driven equipment.

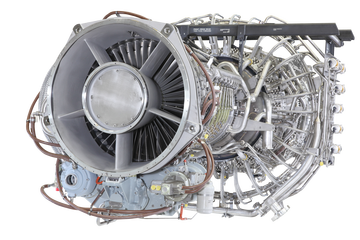

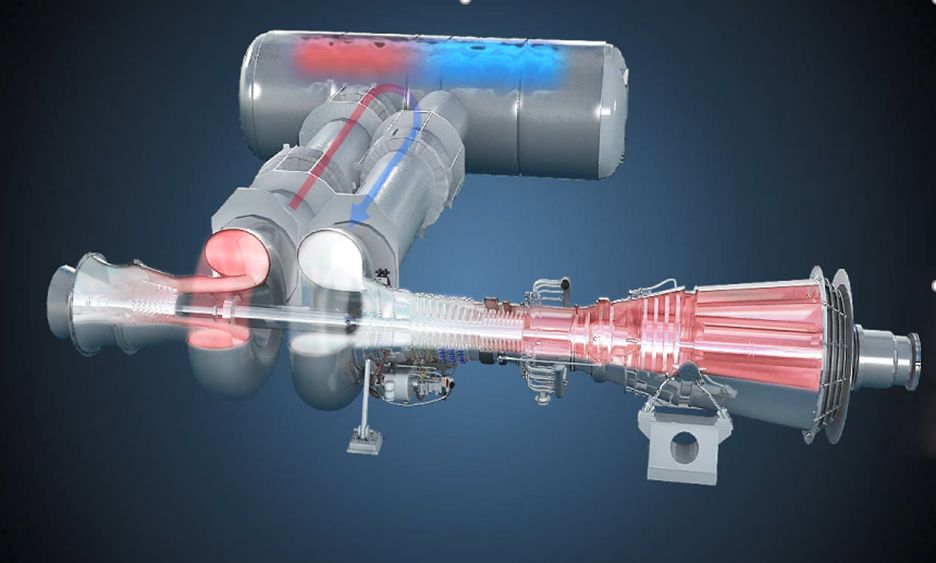

Intercooling technology

The LMS100PB+ gas turbine is the only modern industrial gas turbine to use intercooling technology, which reduces the compressor work by 30%, and enables a total pressure ratio of 42:1, while maintaining compressor exit temperature well below the material capabilities. This characteristic makes the LMS100PB+ the most efficient simple-cycle gas turbine in the world.

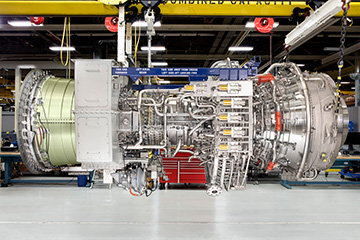

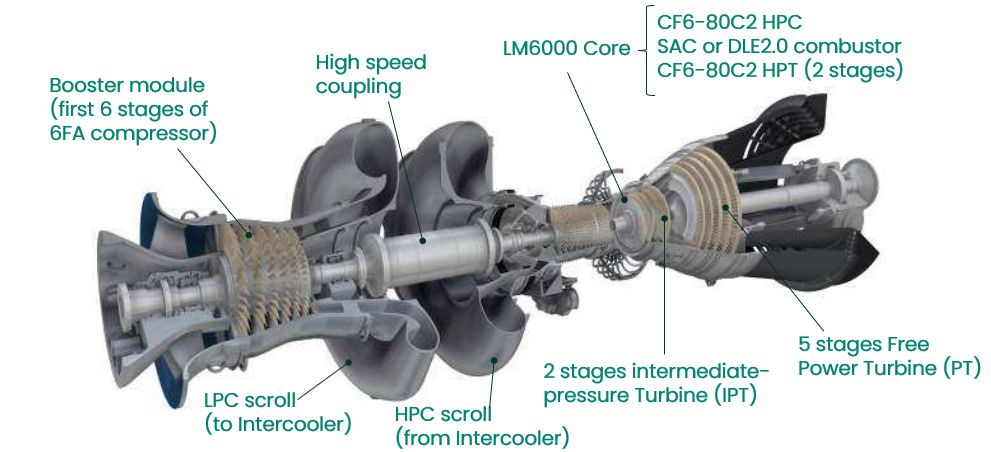

Proven design

The engine combines aeroderivative and frame technologies. The core (high-pressure compressor, combustion chamber, and high-pressure turbine) is from the widely referenced LM6000 aeroderivative gas turbine, with over 1,300 installed units and 40 million operating hours in the field. The booster (low-pressure compressor) is derived from the first six stages of the 6FA gas turbine.

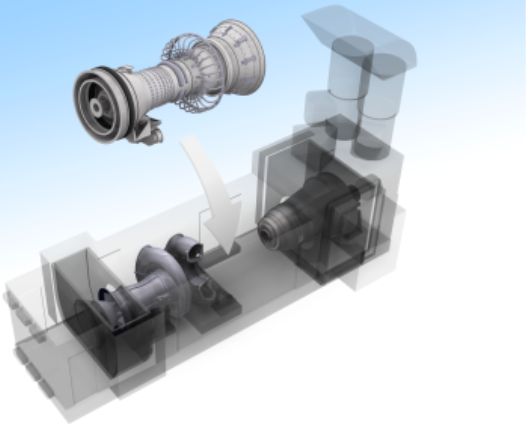

Maintainability

The modular construction and the lightweight aeroderivative design weighs in at less than six tons. This enables supercore swap (core + intermediate-pressure turbine) in less than two days, minimizing downtime during maintenance activities.

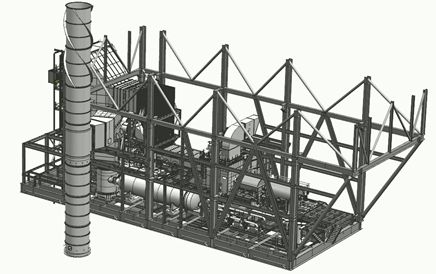

Modular solution

Designed to minimize on-site installation requirements, the fully integrated module contains the LMS100PB+ gas turbine with its package and auxiliary systems, balance of plant including the intercooler, driven compression equipment, and control room. The single-lift, plug-and-play module measures 52x21x25 m (LxWxH) and weights just over 1,000 tons. Upon request, a complete string test of the entire module at full power can be performed before shipping.