Providing proper barriers is a critical step in any successful well plug-and-abandonment (P&A) operation. Baker Hughes can help design, install, and confirm the placement of a permanent barrier prior to well abandonment.

Baker Hughes offers the industry’s most comprehensive range of bridge plugs and cement retainers, including plugs rated to the most stringent ISO 14310 V0 classification.

Our engineers will work with you to identify and install optimized mechanical barriers for both full-bore and through-tubing abandonment isolation. Whether your challenge is permanent isolation or temporary abandonment, our full range of mechanical bridge plugs, cast-iron cement retainers and bridge plugs, and inflatable technologies can be deployed using drillpipe, coiled tubing, or wireline. And, if you need reliable performance in an high-pressure/high-temperature (HP/HT) environment, our bridge plugs offer pressure ratings of up to 25,000 psi (1,724 bar) and temperature ratings as high as 500°F (260°C) at V0 classification, supporting even the most hostile P&A operations

Safe, efficient, temporary well abandonment

For temporary deepwater well abandonment, the Blue Whale™ inflatable service packer (ISP) provides reliable wellbore isolation while reducing project costs. Prior to this technology’s commercialization, isolation in large-diameter casing and open holes offshore required a broad spectrum of packers, procedures, and secondary tools of a specific size and configuration for each job. The Blue Whale ISP replaces a collection of tools with a single, simple tool that provides reliable operation in a range of hole inner diameters (IDs), from 7 to 36 in. (178 to 914 mm) — reducing rig time, storage requirements, and transportation costs without compromising barrier integrity

Cement programs matched to downhole conditions

Our cementing experts can engineer and implement Set for Life™ cement spacer systems matched specifically to each well’s abandonment requirements, ensuring a proper mechanical barrier for reliable zonal isolation. By testing each cement slurry, scientists in our advanced cementing laboratories ensure that the cement we install delivers the gas-tight cement seal your well demands, without the risk of shrinkage.

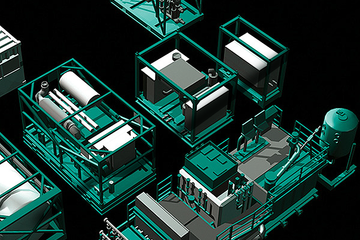

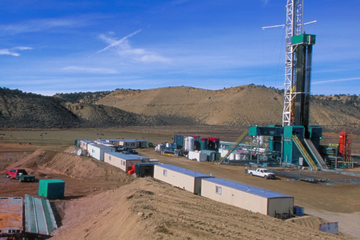

For remote operations without bulk storage and conventional mixing equipment, our Liquid Stone™ liquid cement system can be prepared as a premix. The system is then batch-mixed at the well site and pumped using a coiled-tubing unit. For larger-scale operations, we can provide all the support equipment you need, including a full complement of skid-based pumps, blenders, tanks, manifolds, and hoses. During the operation, we monitor and control the cement pumping from purpose-built data cabins.

For inland waters, Baker Hughes also has several self-supporting cementing barges to safely and efficiently conduct both temporary and permanent well abandonment operations.

Contact your local Baker Hughes representative to find more information regarding our P&A barrier installation options.