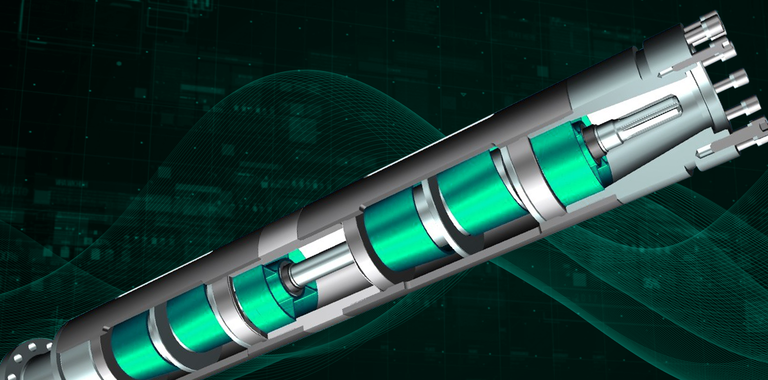

Optimize your electrical submersible pumping (ESP) operations with thrust chambers from Baker Hughes.

Designed on the concept that every action has an equal and opposite reaction, our thrust chambers absorb the resulting down thrust resulting from pushing a large amount of fluid out the discharge end of the pump.

This down thrust force is converted to heat. As the amount of thrust absorbed is increased, an oil cooler is added and increases in size to dissipate the heat.

Choose from various models, depending on the amount of thrust your systems needs to absorb.

SDTC:

- Uses angular contact bearings to absorb thrust

- No oil cooler required

- Slinger rings used to lubricate and cool bearings

HDTC:

- Uses larger angular contact bearings to absorb thrust

- Uses the smallest oil cooler

- Cooler mounts on HPump frame

- Injected oil sprays onto bearings

XDTC:

- Uses a hydrodynamic tilt pad bearing to absorb thrust

- Uses a medium sized oil cooler

- Cooler mounts on HPump frame

- Flooded design is full of oil during operation

UDTC:

- Uses a large hydrodynamic tilt pad bearing

- Largest oil cooler mounts on pad next to unit

- Flooded main chamber is full of oil during operation

Oil Coolers:

- Utilize a filter to always provide clean oil

- Include an immersion heater to prevent condensation forming in the oil

- Use a single motor to circulate and coil the oil

- Use a flow and/or pressure switch to provide health status of the system

Contact us to learn how our thrust chambers can optimize the pumping efficiency of your ESP systems.