Advanced Industrial X-Ray & CT Inspection Systems

Our award-winning Phoenix|x-ray solutions combine advanced industrial radiography and CT systems for an extremely wide range of inspection and metrology applications from scientific and industrial CT and 3D metrology to extremely high-resolution electronics inspections. Industry-leading innovation and expertise is built into every element of our proprietary hardware, software and services – making sure you’re able to find every defect with greater speed and accuracy than ever before.

You won’t need to compromise the accuracy of your results for speed with our powerful, uniquely-designed X-ray CT systems for a wide spectrum of 2D and 3D laboratory and atline inspection tasks, including 3D metrology and analysis. Inspect small to large samples of many different materials, objects and components with the highest precision.

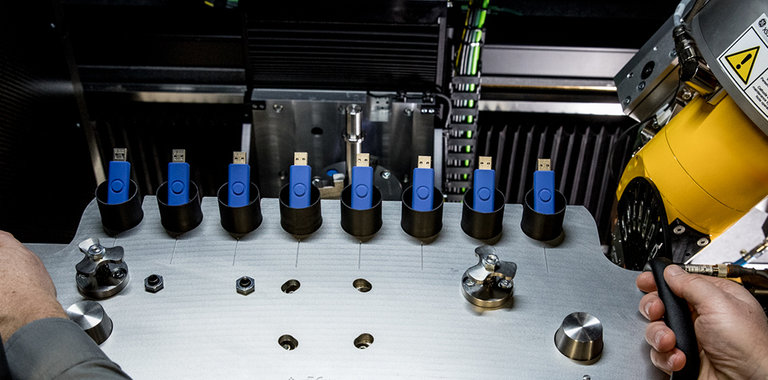

Increase productivity without compromising image quality with in-line and at-line 3D inspection solutions. Our Phoenix Speed|scan CT64 scanner makes fully-automated in-line scanning possible, enabling 4x faster inspections than earlier models and over 100x faster inspections compared to conventional industrial fan-beam CT for large light metal castings.

Access our latest technologies and expertise through our inspection services – from on-demand inspections at our Customer Solutions Centers (CSC), to rentals, training, customization, and consulting services. Inspection scanning services leveraging our latest Phoenix|x-ray CT solutions are available by the hour, scan, or project, in addition to our remote services for 24/7 technical support, problem diagnosis support and more.

Discover Our Products

Phoenix X|aminer

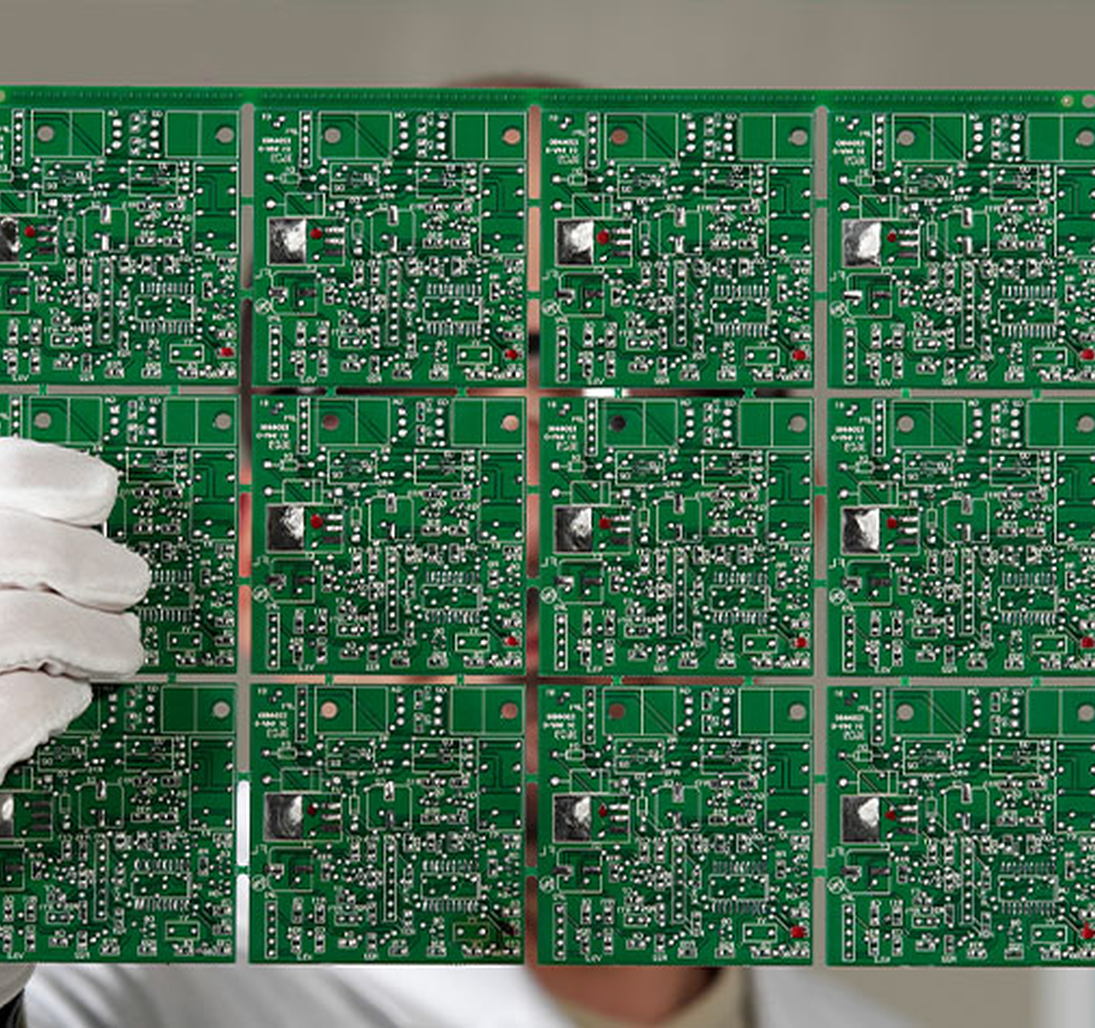

Entry level 2D microfocus X-ray solution of unprecedented price-performance ratio for quality control of electronics such as components and PCBA, offering brilliant productivity and profitability across the globe with hundreds installations and over 10 years great reputation on the market.

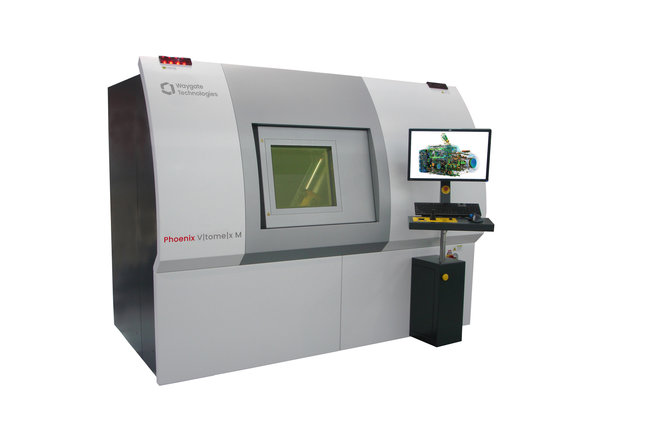

Phoenix V|tome|x M300

The world’s first microCT scanner designed for 3D metrology and analysis with scatter|correct technology to automatically remove scatter artifacts for higher image quality. High-quality 3D micro- and nanoCT results and outstanding metrology precision with 300 kV penetration power enable improved safety and throughput.

Phoenix V|tome|x C450

A powerful, compact 450 kV precision CT scanner with optional Metrology edition specially designed small high for absorbing parts and large parts.

Its production-oriented, low-maintenance design offers speed and flexibility allowing for combined semi-automated non-destructive testing and 3D metrology.

Phoenix Nanotom® M nanoCT® scanner with premium performance

The Phoenix Nanotom® M is a nanofocus X-ray CT system for scientific and industrial computer tomography (microCT and nanoCT®) and 3D measurement technology. The system offers unique spatial and high-contrast resolution for a wide range of samples and applications. The fully automated execution of the CT scan, reconstruction and analysis process ensures easy operation and fast, reliable CT results. Precise and reproducible 3D measurements of complex objects and the automatic creation of initial sample test reports within an hour are possible.

Phoenix V|tome|x L 300

The Phoenix V|tome|x L 300 is a versatile high-resolution walk-in cabinet microfocus system with nanoCT® option for 3D computed tomography (structure failure analysis & metrology) and 2D non-destructive X-ray inspection.

Phoenix V|tome|x L450

As the next technical expansion stage of the Phoenix V|tome|x L300 system, the Phoenix V|tome|x L450 provides even more flexibility, sample size and with its 450 kV / 1500 W minifocus and its optional 300 kV microfocus X-ray tube more penetration power to make it an excellent solution for void and flaw detection and 3D metrology of castings, large assemblies and AM parts.

Talk to one of our advanced industrial X-ray and CT inspection experts.