|

Overview

A key component in the production systemProduction systems typically have complex multiphase flow streams where oil, gas, water or particles like sand may be combined. Our subsea separation systems combine technologies that can handle gas-liquid, liquid-liquid or solids separation (or a combination of them) for flow management. They also condition the flow for further boosting, transportation or reinjection, while reducing the risk of flow assurance issues during production.

Increased production with reduced CAPEXSubsea separation offers better conditions than topsides separation for avoiding flow-assurance issues like the formation of emulsions and hydrates. Handling of production fluids can be done closer to the production wells and more efficiently at higher pressures. Our subsea-separation solution can de-bottleneck your topside production facilities by freeing up storage and transport capacity—giving you the potential to increase production and reduce related CAPEX.

Expertise allied to experienceBaker Hughes has the required expertise and experience to design and supply the optimal subsea separation system for you. Our field-proven technology and experience includes Equinor’s Troll C, the world’s longest-running subsea-separation and -reinjection system—operating since 2001 and enabling significant increases in the field’s oil production.

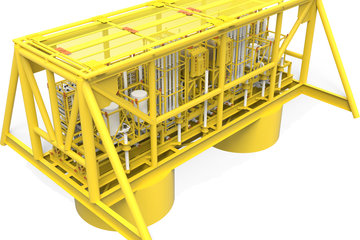

Robust and simple solutionsOur building-block approach includes an open-interface that allows us to partner with suppliers of complementary technology to ensure we design a robust and simple solution that meets your field requirements. We can also provide a reliable full-system design where separation is integrated with our subsea-boosting and -compression solutions for transportation and/or reinjection.

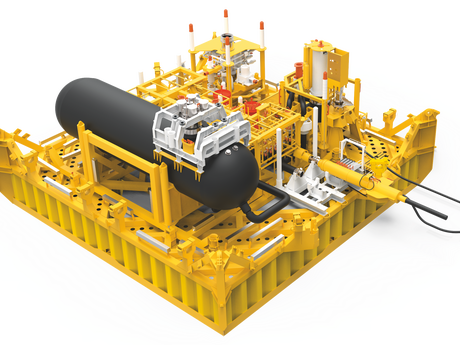

Gravity separatorsOur gravity separators are also tough and simple. They can achieve three-phase separation (gas, water, and oil) and are designed with sand-handling capabilities. Our semi-compact gravity separators are an improvement on traditional gravity separators and provide robust solutions for deepwater applications, where they can be combined with internal separation-enhancing devices and bulk separation equipment for gas, water and/or sand handling.

Compact separatorsOur compact separators are designed to handle high-pressure environments. In ultra-deepwater applications, conventional gravity separators have limitations due to the high-pressure environment. In these conditions, smaller-diameter vessels used in compact separation become more attractive. While gravity settling and coalescence are the dominant mechanisms in conventional gravity separators, compact separation solutions enhance coalescence of the different phases by other means—typically centrifugal forces or turbulence. In-line, pipe-type and cyclonic separation devices all form part of our compact separation solutions.

Features and benefits include:

|

Get in touch with an expert.

Your request has been submitted.

Thank you for your interest. A specialist will be in touch with you shortly.