One of the most common images associated with oil and gas operations is a burning flame spouting out of a tall, pole-like structure at a facility. But what exactly is that and why is it happening? Is it bad for the environment? Here are 5 facts to know about flaring.

1. For starters, what exactly is the pole with a flame we often see at industrial sites?

The tall, thin structure with flames or steam coming out of the top is called a flare stack. It’s a gas combustion device used at industrial sites to burn off waste or other unwanted gases.

2. So why is the flare stack producing fire?

A flare stack produces a fire as part of controlled burning taking place for a few typical reasons: 1) as part of testing to stabilize pressure and flow from a well 2) managing waste gas that can’t be captured or processed 3) for safety or emergency situations to release pressure. Flare stacks are mostly found in refineries, chemical and petrochemical plants, natural-gas processing plants, offshore exploration platforms, well heads and landfills.

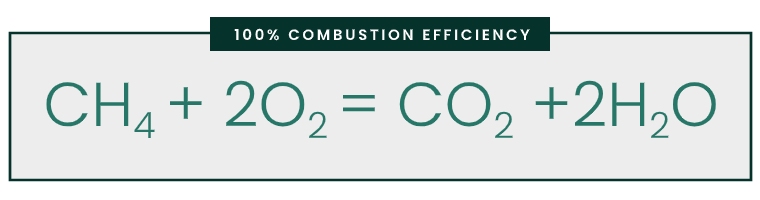

3. Does flaring release carbon emissions?

The flare stack’s main purpose is to combust vent gas—a large portion of which is methane. When methane (which you might remember from chemistry class as CH4) is burned, it produces carbon dioxide (CO2) and water (H2O).

If the methane is not burnt, it will be released into the atmosphere as-is, and it is invisible or looks like steam (for downstream flares).

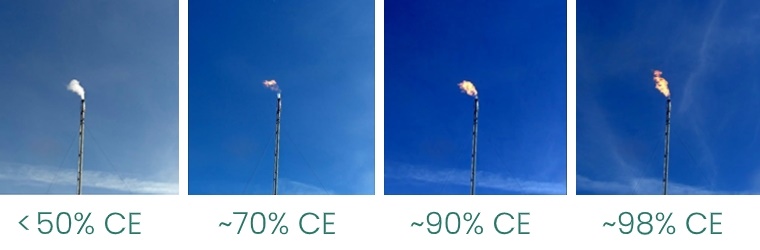

Methane is 25 times more damaging to the environment than carbon dioxide when it comes to warming the planet over a 100-year period. This explains why that flame is so important. Operators need to have flare stacks optimized for combustion efficiency, so as much methane as possible is burned, converting it into carbon dioxide and minimizing a facility’s long-term carbon dioxide equivalent emissions.

4. What are some common misconceptions about flaring?

First of all, people see fire and automatically think it’s dangerous. But the reality is, if someone sees a flare stack venting methane masked with steam, that’s far worse. The bigger and brighter the flame coming out of a flare stack, the less of an impact that facility is having on the environment, from a carbon-emissions standpoint.

5. How can oil and gas companies continue to flare if they want to reduce emissions?

Companies can reduce routine flaring by finding uses for the gas, instead of burning it. Capturing this gas gives operators and opportunity to produce more energy. However, technology today also allows operators to monitor and measure combustion efficiency in real-time – meaning they can reduce the amount of carbon emissions released by flares. With flare optimization solutions available today, facilities can now operate at 96-percent efficiency or higher. This improvement can cut up to 12,100 metric tons of CO2 equivalent emissions per flare annually.

You can find additional information about flare optimization solutions here.

Energy Forward Stories

Sign up to stay up to date on the latest innovations and people shaping the future of our industry.