Highlights

Highlights

Benefits

- Avoid H2S migration into the motor and cable with metal-on-metal primary seals

- Confirm proper connection prior to deployment

- Mitigate fluid ingress into the motor with minimal fluid leak paths

Applications

- Wells with high levels of H2S

- Wells with high gas content

- Wells that experience thermal cycling

Overview

Ensure the electrical integrity of your electrical submersible pumping (ESP) systems in harsh downhole conditions with the CentriLink SHIELD™ harsh-environment motor lead extension (MLE) from Baker Hughes. Adapted from field-proven safety valve technology for completions in demanding deepwater environments, the CentriLink SHIELD MLE’s robust design mitigates the potential for gas and fluid ingress into the motor and the power cable.

Design advances improve system reliability

The CentriLink SHIELD MLE seamlessly integrates with CENtrilift™ XP motors and CENtrilift XP motors with Vanguard™ construction. The MLE includes several design features that prevent installation-related issues that can negatively impact system uptime.

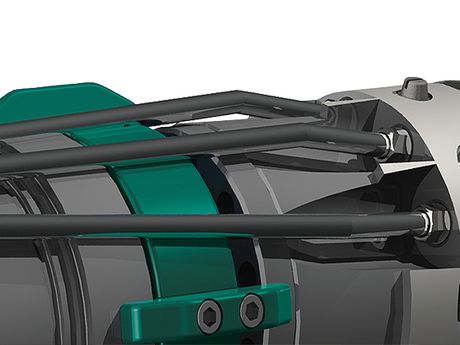

The MLE incorporates three metal-on-metal primary seals that feature a compression fitting assembly attached to non-corrosive Monel encapsulated copper conductors. The seals seat securely into a tapered port in the motor head assembly.

By eliminating the elastomeric materials and the majority of the potential leak paths typical in standard plug-in MLE designs, the CentriLink SHIELD MLE handles pressure changes and reduces the potential for H2S migration into the motor and cable. As a result, your system is protected from catastrophic damage resulting from rapid gas decompression.

Individually encapsulated conductors allow your ESP system to continue operating even if one conductor shorts out. This gives you the time to plan an intervention and avoid production interruptions. The optimally spaced conductors also mitigate electrical arcs that lead to phase-to-phase electrical failures.

Ensure faster installations and robust connections

Verify that a tight seal has been achieved prior to running the ESP downhole with the CentriLink SHIELD MLE’s pressure test ports. The ports are located above the seals to prevent introducing a potential leak path. All three seals are pressure tested simultaneously to minimize the time required to complete the process.

Because the MLE is traditionally the most vulnerable component during ESP installation, the CentriLink SHIELD MLE was designed with a low-profile, recessed connection to the motor to prevent possible damage as the ESP is deployed downhole. The self-aligning connection reduces installation time while eliminating the potential for human error during the MLE-to-motor connection process.

Contact us today to learn how the CentriLink SHIELD MLE can improve your ESP system longevity in challenging downhole environments.