What is CT scanning inspection technology?

In medicine, physicians know that you can get more accurate imaging (and information) from a CT scan, than a traditional x-ray. The same holds in manufacturing quality assurance, and Reuter-Stokes has taken the next step by adding this vital inspection technology to its in-house production process.

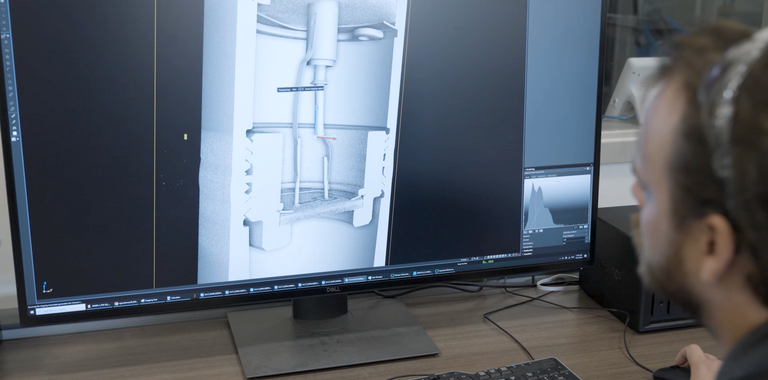

CT scans, more formally known as x-ray computerized tomography, provide a three-dimensional view of solid-state materials that can be examined in "slices" or "layers" rather than the static 2D images produced by traditional x-ray inspections.

This inspection technology delivers more information than standard x-rays with their overlaying features visible in the view through the sample, allowing visualization of the part from any virtual section. This allows analysis of a part's internal features without cutting or disassembling it as you would in a destructive test.

While destructive testing methods allow you to get inside the part, you do run the risk of destroying the defect you're trying to find when you cut apart the product - and you have only a few mechanical cuts, while CT allows you to virtually cut in hundreds of slices to be sure to find any defect. Another challenge is determining if the root cause of the defect occurred during the destructive inspection - CT scanning eliminates these issues.

Using industrial CT scanning with much higher detectability than in medical CT, it's possible to zoom in on a part's tiniest features and get deeper into the object. You can also evaluate a part's dimensional information and internal geometries - things that are difficult to do with x-rays and or with conventional CMM techniques, respectively. This also helps avoid needing to perform destructive measurements to get these geometries. These measurements can be accurate down to micrometers.

What are the benefits of CT scanning inspections?

3D CT scanning offers multiple benefits over traditional x-ray inspections, including:

• Better resolution and cleaner images

• Better penetration and visualization of a part's interior

• Easier measurement and inspection for dimensional tolerances

• Video sweeping of 2D slices across from an axis of orientation

• Digital analysis of images

• Image storage

When you're able to see inside a product and its various layers, you get a full view of its internal and external geometry with accurate spatial resolution, comparing each slice against a CAD model. This provides a full picture so you can easily identify design issues and discrepancies, pinpoint flaws, and perform other quality control tests to ensure your parts are structurally and functionally sound.

How does Reuter-Stokes use CT scanning inspections?

Reuter-Stokes has historically used external scanning service providers, including fellow Baker Hughes business, Waygate Technologies. Waygate Technologies is an industrial inspection solutions provider and the world leader in nondestructive testing (NDT).

We can cite multiple case studies of successful CT scan inspections that helped us remedy potentially costly defects. In one scenario, CT scans successfully identified the root cause of an insulation resistance failure and helped us verify the corrective action. It allowed us to clear existing components for use as-is.

Another testing situation helped us trace a flaw's origin by eliminating multiple probable causes non-destructively. This contributed to continuous improvement for this part, giving us insight that will help us eliminate possible failure modes in future designs. Additionally, CT scans also can help us see details that are important when considering and qualifying vendors.

We have been using CT scanning to inspect braze quality in ceramic feedthrough inspections. In doing this, we examine both slices of a part in distinct locations and also do a 3D reconstruction of the part. This allows us to look closely at all details to see if the brazing is working as it is designed and intended. You can do it with 2D x-ray, but you would see shadows on the picture, and it wouldn't be as crisp or provide details at a micro-level.

Why did Reuter-Stokes move to in-house CT scanning?

As we scanned more parts using services from Waygate Technologies, we realized investing in our own CT equipment would make sense and contribute to our quality assurance focus for such reasons as:

• Reduced scrap

• Better quality production

• Faster part delivery thanks to accelerated root-cause analysis

• Continual improvement in assembly processes

• Quicker new product development efforts

In the nuclear sector in particular, there is absolutely no room for error. Our sensors must provide accurate and reliable data. As a result, the manufacture and production of Reuter-Stokes technology must be similarly exact - there is no room for error!

Using the CT scanner, we can analyze all the components and materials used in the manufacture of our technology. If there is something amiss on dimensions, a defect, or a contamination present, we can pick it up. Identifying any faults in the early stages of manufacture saves significant amounts of time and reduces our cost of quality overhead.

Without the CT scanner, there would be a trial-and-error approach to identifying issues; In one example with the CT scanner, we were able to identify a defect in a component in just one hour.

A key advantage is that we can integrate the system at the design stage of a new product. This helps us to avoid making decisions at this stage that could reduce efficiency and slow us down. We are now in a position to bring new products to market earlier.

Left: Paul Turkal, Senior Welding and Material Labs Manager;

Right: Jonas Burke, Senior Engineer, Materials Science

More about the machine

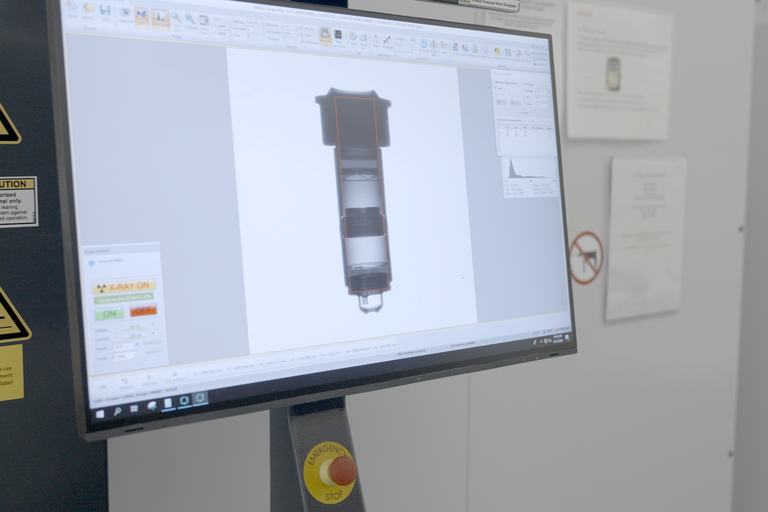

This versatile high-resolution dual-tube 180 kV nanofocus/300 kV microfocus system for 3D computed tomography (microCT) and 2D non-destructive x-ray inspection handles large samples up to 50kg and up to 900 mm in diameter with extremely high precision.

The unit can test various materials and densities, ranging from gold to plastics in sizes from 0.1" to 30" in diameter and 0.5" to 20" in length.

With its unique Scatter|correct cone beam CT technology, we can scan high scattering parts with extremely high image quality like line CT, but several hundred times faster.

This gives us a flexible multi-purpose in-house inspection solution for void and flaw detection and 3D metrology of parts, ensuring the safety, quality, integrity and consistency of Reuter-Stokes products.

Model: Phoenix V|tome|x L300 Microfocus CT System from Waygate Technologies