SMR Design Characteristics

This is an excerpt from our white paper 'Energizing the Future: Exploring the Promise of Small Modular Reactor Technologies'

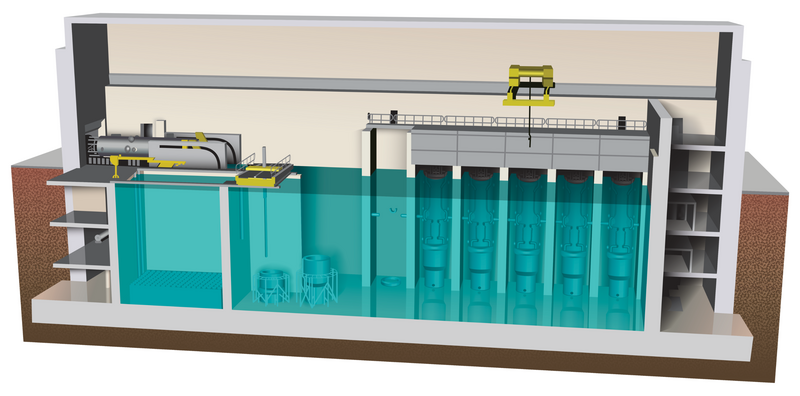

Small Modular Reactors, or SMRs, have several distinct features and design principles that set them apart from traditional large-scale nuclear reactors, including:

Enhanced safety features

Small Modular Reactors prioritize safety by using passive safety systems that require no external power or operator intervention to function. These systems rely on natural processes like gravity, convection, and chemical reactions to shut down the reactor and remove excess heat in an emergency. Redundant safety systems and diverse safety barriers are also incorporated to mitigate the consequences of potential accidents or equipment failures. Further, SMRs are designed to maintain inherent reactor stability under various operating conditions, reducing the likelihood of accidents or unplanned shutdowns. Advanced control systems and feedback mechanisms help stabilize reactor operation and prevent instabilities or power excursions.

Modular construction

Modular construction involves fabricating reactor components in a factory setting and assembling them onsite. This approach offers several advantages, such as standardized modules that can be replicated and mass-produced, rigorous quality control measures, parallelization of activities, and significant cost savings due to reduced construction times, lower labor costs, and minimized onsite work.

Scalability

SMRs offer scalability in size, capacity, and configuration. They can be deployed individually or in clusters to meet varying energy needs. SMRs are designed to integrate seamlessly with existing grid infrastructure and can be adapted for various applications beyond electricity generation.

Cost-effectiveness

SMRs are cost-effective and have reduced capital investment compared to large-scale nuclear reactors. Their modular design allows for standardized production of reactor components in factory settings, reducing manufacturing costs. The smaller size of SMRs enables more efficient use of materials and resources, further contributing to cost savings in construction. Additionally, SMRs can be built in stages, reducing the upfront capital investment required for project development. SMRs have a smaller scale and modular design, which lowers financing risks. This approach spreads financial risk over multiple project stages, increasing investor confidence.

Flexibility in deployment and grid integration

SMRs offer advantages due to their modular design, enabling standardized production, shorter construction times, and scalable deployment. Multiple units can operate in parallel, adjusting power generation to match fluctuating demand. The versatility of SMRs suits various locations and applications, including baseload, load following, and peaking power. Integrating well with existing grids, SMRs enhance stability and reliability as distributed resources, reducing reliance on centralized plants and long-distance transmission. Their modular, scalable nature facilitates efficient grid integration and load following while providing process heat for industrial, heating, and desalination needs.