Small Modular Reactor Research & Development Initiatives

This is an excerpt from our white paper 'Energizing the Future: Exploring the Promise of Small Modular Reactor Technologies'

Though commercialization of Small Modular Reactors remains uncertain, innovations in modular construction, digitalization, and automation are expediting SMR deployment and driving cost reductions.

Beyond developing and optimizing advanced reactor designs, there are several crucial ongoing research and development initiatives:

Materials Science Research

Materials science research is essential for developing reactor materials that can withstand high temperatures, neutron flux, and corrosive environments in SMRs.

Testing

Other research and development initiatives focus on testing and qualifying materials for reactor components, including fuel cladding, structural materials, coolant systems, and containment structures.

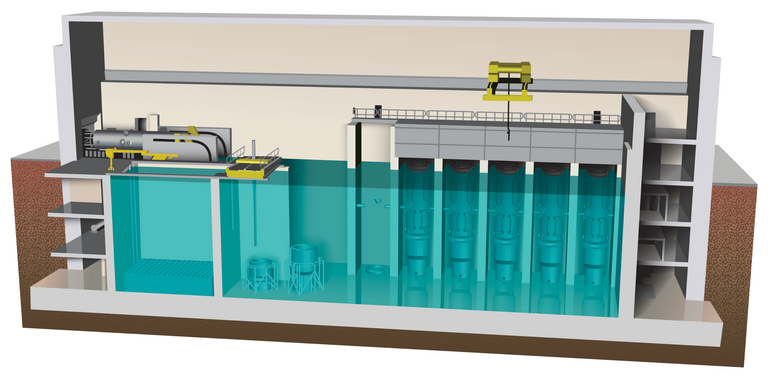

Modular Construction

A significant effort is underway to optimize modular construction techniques and manufacturing processes for SMRs, including factory fabrication, assembly line production, and quality control measures. Research aims to reduce construction costs, accelerate project schedules, and improve the efficiency and reliability of SMR manufacturing.

Digitalization

Certain R&D programs are exploring digitalization, artificial intelligence, and automation technologies to optimize SMR operations, maintenance, and safety. Research focuses on developing digital twins, predictive maintenance algorithms, and advanced control systems to enhance reactor performance and reduce operational risks.

Grid Integration

Grid integration studies, energy systems modeling, and techno-economic analysis to asses the role of SMRs in future energy systems is another area of active R&D. This research aims to evaluate the technical, economic, and environmental impacts of SMR deployment, identify optimal deployment scenarios, and inform policy and regulatory decisions.