A problem in need of a fix

Steam methane reformers produce hydrogen and carbon monoxide, together known as synthesis gas or syngas. Syngas is produced by reacting natural gas and steam in the presence of a catalyst and under high temperature, 950 - 1100°C. In addition to being the feedstock, natural gas is also used as the fuel to heat the production material in catalyst tubes. Using high volumes of flammable materials makes steam methane reforming a high risk process. The startup procedure poses the most risks. If not controlled, uncombusted natural gas can accumulate in the firebox and then explosively ignite. Outdated safety systems have been used for decades and it is incorrectly assumed that they are sufficient.

The Yara Tertre steam methane reformer was designed and built in the 1960s. There are nine rows of 20 Hamworthy burners per row. Like many reformers in the early years, the start-up process was not automated, but instead used human visual examination and checklists to bring the SMR up to the minimum operating temperature. Unfortunately, when human elements are involved, there are increased risks.

Over the years, the Yara Tertre process has run smoothly, but an explosion occurred in 2009 during start-up. It was caused by an erroneous introduction of uncombusted natural gas into the firebox followed by explosive combustion. Two people were injured and the SMR was destroyed. Yara rebuilt the equipment, implemented improved safety systems and restarted the plant in 2011.

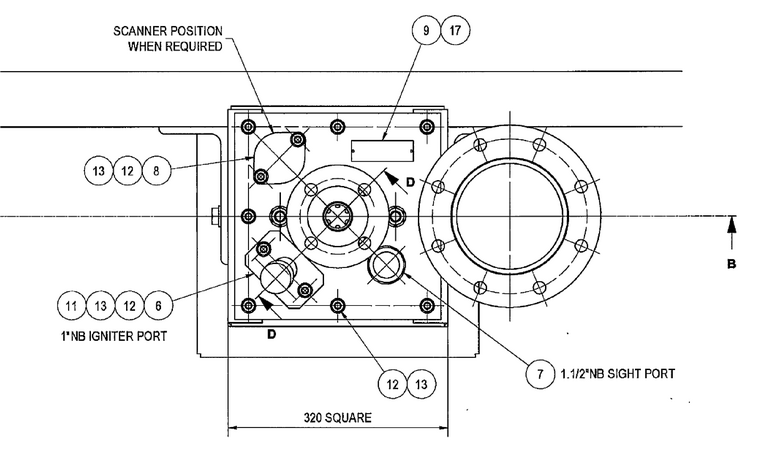

A top view of the Yara Tertre burner design and shows the ignition and visual ports as well as the preferred sensor mounting location.

Among other changes, 36 flame sensors were installed on the arch burners of the firebox and were connected to the burner management system (BMS) to lessen the human element risk. The flame sensor outputs were used as inputs to the steam methane reformer start-up procedure to ensure safe commencement of operations.

Because of the burner configuration, the sensors that were installed could not detect the flame in the sensor position of the burner. The failure to detect the flame is because the location for the sensor position offered an indirect view of the flame which provides a lower intensity of light. Due to this problem, the sensors had to be installed in the igniter port. The igniter port does have a direct view of the flame. During start-up, the flame sensors had to be removed from the burner so an igniter could be inserted in the port and flame sensors were reinstalled after ignition.

Once again, the flame sensors selected were not up to the task. The Yara Tertre is a top-fired design and the arch burner flame sensors are in a penthouse above the firebox. With the burners in this location, ambient temperatures on the burner fronts can exceed 150°C, which is well beyond the temperature capability of most flame sensors in use today. The sensors installed in 2011 had a maximum operating temperature of 93°C and the sensors failed due to the high temperatures in the penthouse. Because of this they were bypassed and eliminated from the start-up process. The technology was not robust enough to handle the temperatures, so a harsh environment sensor had to be found to solve the problem.

Reuter-Stokes provided a solution

Yara needed a flame sensor that could provide high reliability in the harsh environment of the steam methane reformer penthouse. They also needed better sensitivity that could detect flame with an indirect view. Yara partnered with Reuter-Stokes, who had been on harsh temperature applications on OEM gas turbines over the last three decades. The flame sensor chosen was the Reuter-Stokes Flame Tracker Dry 325 (FTD 325) - an innovative harsh environment UV sensor with exceptionally high sensitivity.

Reuter-Stokes’ FTD 325 is comprised of a hot end that attaches to the burner sight tube, a mineral insulated cable that is 30 feet long, and a cool end for amplification and signal conditioning. The sensor is a single-piece assembly and is hermetically sealed from end to end. The hot end has a maximum operating temperature of 325°C, well beyond the ambient temperature near the burner fronts in the reformer penthouse. This temperature capability was the missing link to installing a successful solution in the penthouse.

Yara Tertre wanted to test one of the FTD 325 sensors on the steam methane reformer before committing to a complete installation. Yara first took temperature measurements on four burners over a 24-hour period. Infrared temperature measurements were made on four different burners near the scanner position on the burner front, with measured temperatures ranging from 108°C to 159°C. Yara installed an FTD 325 on one of the burners in the sensor position. The sensor was able to perform flame supervision using the indirect view of the flame and ran for six months with very satisfactory performance and no reliability problems.

Based on the successful six month test with a single FTD 325 sensor, Yara installed an additional 17 sensors on arch burners. The sensors are used during the startup process, which is the highest risk part of operations. They placed two sensors on each of the nine rows of burners. The hot ends were connected to the scanner positions on the burners. The cool ends were mounted on the wall at the end of the burner rows. The 4-20 mA current loop outputs are simple to connect to the burner management system.

Several permissive checks are performed, including a purge of the firebox. Then the FTD 325 sensors are used during the light on sequence to ensure that a row of burners is confirmed lit before lighting the next row. Each row is similarly lit and checked before the next row is ignited. Best of all, they are not installed in the igniter port and don’t interfere with the ignition process. They are reliable enough to stay in place for years in these harsh environments.

FTD 325 Hot end connected to the sensor position of the burner

FTD 325 cool ends with excess MI cable in a loop

Conclusion

Yara Tertre and Reuter-Stokes have successfully partnered on the project. The steam methane reformer was started in October 2018 with the 18 FTD 325 sensors in operation. With their progressive approach to safety, Yara leads the way in industry readiness.

Since then, the sensors have performed well in the harsh environment of the penthouse with no failures. There have been at least ten starts since the 2018 installation and the FTD 325 sensors have been used in each start.

Because the Reuter-Stokes FTD 325 sensor is engineered for the extremes of harsh environment sensing, it can operate under conditions where other sensors cannot.

FTD 325 plays an important role in making steam methane reformers safe. Other sensors have tried to achieve these required temperatures and failed.

With the long history of monitoring harsh environments on gas turbines, the Reuter-Stokes FTD 325 was able to easily eliminate the human element and restore confidence in this high-risk application.