Webinar: The Secret to Safer Steam Methane Reforming

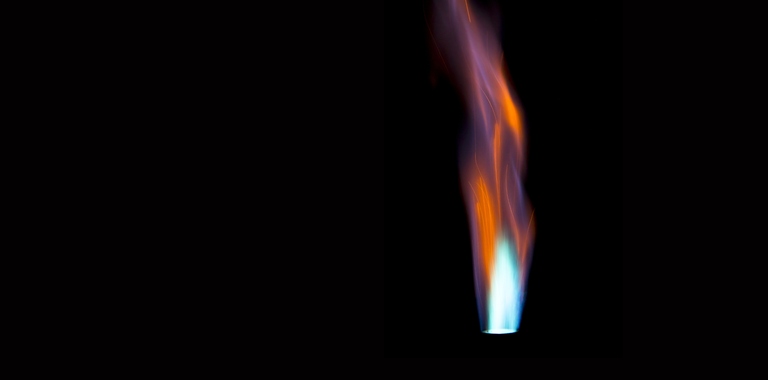

If there’s a safer way to do something, people should know about it. Today, steam methane reforming accounts for nearly all commercially produced hydrogen in the United States. It’s widely used – but not always perceived as safe. Why? The perception is driven by the potential risk involved in the start-up process. Fuel can accumulate and result in an explosion – if proper safety precautions aren’t taken.

Currently, many steam methane reformer operators use manual processes to verify proper flame operation. The result is unnecessary risk that has led to disastrous incidents. Let’s educate these operators that there’s a better way. We can automate flame sensing to improve safety, even in these high-temperature conditions that are too harsh for most technologies. These risk-reduction solutions are already available – we just need to get the word out.

Key Learning Objectives

- Describe the use of steam methane reformers and the critical role they play in multiple industries.

- Explain the risks involved in the start-up process of steam methane reformers.

- Evaluate current steam methane reformer safety practices concerning flame sensing.

- Identify technologies that work in these harsh environments.

Speaker

Mike Spalding

Application Engineer

An expert in ultraviolet sensing, Mike Spalding brings in-depth engineering knowledge of applications for flame sensing in hazardous environments including power generation and industrial heating. His career includes more than 20 years of industry experience with Reuter-Stokes, including work within its corporate parents, first GE and more recently Baker Hughes. He holds a degree in electrical engineering from Texas A&M University and resides in Twinsburg, Ohio.