Highlights

Benefits

- Ability to sense wire breakages from 15 meters away

- Detect unloaded tensile wires under ancillary equipment

- Contribution to life extension initiatives

Features

- Provision of integrity assurance

- Management of end-of-life scenarios

- High frequency data collection providing analysis assurance

Applications

- Installed to the outside sheath therefore no compromise to riser integrity

- ROV, diver or topside deployable

- Applicable to flexible risers from all manufacturers

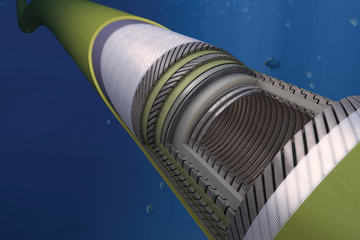

Structural Integrity Inspection and Monitoring System for Protecting Flexible Risers

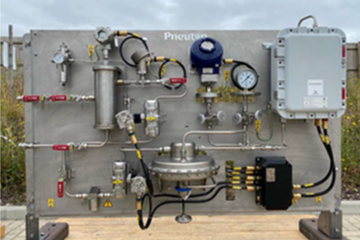

MAPS® is the industries premium technology for the management of flexible risers from all manufacturers. The technology is a non-destructive, non-contacting technique for measuring stress within the steel armor wires with a unique capability to assess the integrity of the primary load-bearing elements within the pipe design. MAPS® is available as an inspection service or an installed monitoring system with continuous data collection.

New Level of Integrity Assessment

Conventional inspection technologies require the exact defect location and equipment must be positioned over the affected area. Critical pipe locations are often difficult to reach because they are subsea or ancillary equipment can prevent access. MAPS® technology can identify a wire defect including breakages from 15 metres away, including assessing integrity in and near the splash zone and up to the top termination, where there may be no access to the pipe. Scanners can be used above or below sea level which are installed by rope access, diver or ROV.

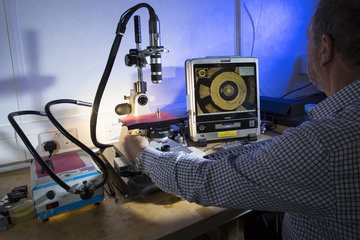

Engineering Principle

MAPS® Technology detects the change in applied stress within the steel armouring wires of a flexible riser when the bore pressure is changed. If a wire does not demonstrate a change in applied stress under a change in pressure, then the wire is deemed non-load bearing which is an indicator that the wire has suffered fatigue damage. It is measured using an electromagnetic stress measurement system, which operates using a basic physical property of ferritic steel as the magnetic properties are sensitive to mechanical stress. The inspection system magnetically couples to the steel armouring layers through the flexibles outer sheath which does not require sensors or special components to be incorporated at the riser manufacturing stage.