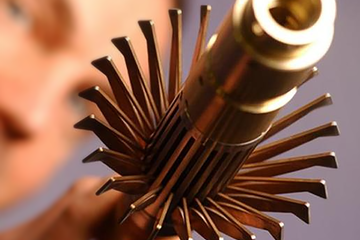

Evaluating the integrity of your casing is critical to ensuring the optimal operation of your producing assets. Casing inspection services from Baker Hughes give you precise pipe integrity and corrosion evaluation to accurately assess the strength of your casing and tubing strings.

Detailed integrity analysis

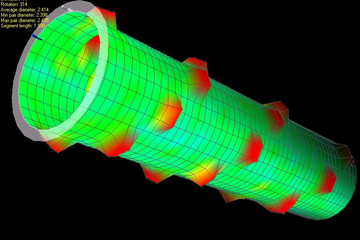

Tools like the High-Resolution Vertilog™ (HRVRT™) service provide a wealth of casing integrity information that guides your remediation planning. The service uses magnetic flux leakage (MFL) to locate and quantify both internal and external corrosion defects in your casing string—with increased accuracy for length, width, and depth. This data serves as input for accurate burst pressure calculations while characterizing defects near the wellhead.

Your operation benefits in several key ways.

Optimize your remediation planning. Get detailed insights to the integrity of your casing to eliminate unnecessary remediation work and minimize any unplanned production outages related to corrosion

Verify the effectiveness of your corrosion mitigation. Accurately track the progression of corrosive penetration into the tubing over time to evaluate the performance of your cathodic protection and corrosion inhibitor treatment programs

Locate problem areas with ease. Distinguish between metal-loss (due to corrosion) and metal-gain (due to hardware) features and distinguish between general corrosion and isolated pitting

Reduce measurement time. Shorten the time for data collection and analysis with flexible and efficient data acquisition options that improve data accuracy and operational safety

Contact us to learn more about how Baker Hughes casing inspection services can accurately evaluate the integrity of your casing for improved operation and remediation planning.