Overview

At Process & Pipeline Services (PPS), we understand how crucial it is for our clients to have efficient, reliable pipeline networks that ensure safety, maintain integrity and maximize throughput.

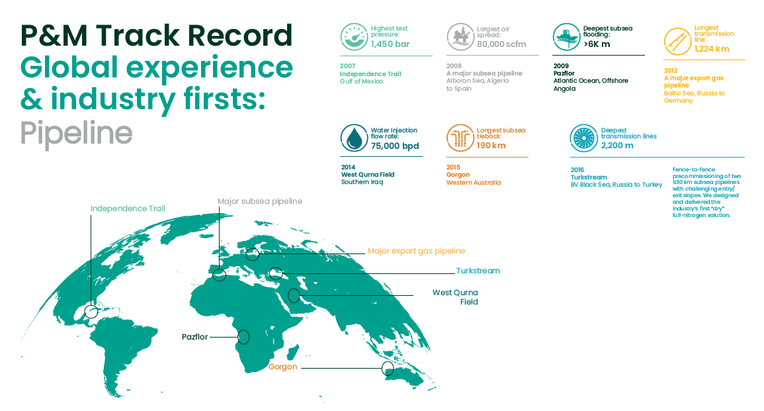

From pioneering early pipeline technologies to executing some of the world’s most complex projects—Nord Stream 1 & 2, Greater Tortue Ahmeyim, Gorgon Jansz-Io, TurkStream, and Texas Tuxpan - our track record speaks for itself.

Why Choose Baker Hughes PPS?

Our success is built on decades of experience, continuous innovation, and the trust of our global clients. We combine advanced technology with deep domain expertise to deliver tailored pipeline solutions across the full asset lifecycle.

Our Core Capabilities:

- Advanced Pipeline Pre-Commissioning

Expertise in managing complex challenges, whether due to: water depth, pipeline diameter, spread size, or remote deployment. - Pipeline Cleaning & Maintenance Campaigns

Comprehensive mechanical and chemical cleaning programs using proprietary PPS-designed chemicals and methodologies to ensure optimal flow and asset integrity. - Methane Emissions Reduction Solutions

Innovative approaches to reduce methane emissions during gas pipeline maintenance and blowdown operations with services such as mobile gas recompression and nitrogen purging. - Pipeline Decommissioning Services

Engineered solutions for safe, efficient, and environmentally responsible pipeline retirement.

Setting Records in Depth, Distance, and Performance

From record-breaking subsea depths to the world’s longest transmission lines, we deliver unmatched expertise and innovation across every stage of the pipeline lifecycle.

Discover our services

Pipeline pre-commissioning

At Baker Hughes’ PPS, we are a single source provider of pipeline pre-commissioning services. Our services employ a modern, reliable fleet of equipment – flooding and testing pumps, compression and high pression boosting, nitrogen generation, subsea units - backed by knowledgeable, experienced engineering and field teams. Our local capabilities will deliver all over the world with the same stringent standards, and same attention will be given to extreme and challenging projects than very regular scopes.

The pre-commissioning of pipelines involves flooding, cleaning and preserving, testing, dewatering, and drying of new systems. These services are performed to confirm the pipeline’s integrity, but also to make certain quality-controlled conditions are achieved. For the pipeline operator, this ensures an uneventful startup and continued successful operations.

We will support our clients working to re-purpose their pipelines for CO2 (carbon dioxide) or H2 (hydrogen) applications. Our expertise in decommissioning (gas and liquids), deep cleaning and drying will ensure success of such projects, offshore and onshore.

Upon completion of pipeline laying and all associated construction activities, we can support the pre-commissioning process with providing the following services: pipeline flood, clean and gauge pig from the offshore laydown head towards the onshore pull-in head. This will remove any debris such as sand and silt that may have entered during pipe lay and prove the integrity of the pipeline internal bore confirming that no damage was sustained during pipe lay. We own an extensive and diverse fleet of flooding and triplex pumps allows tailor made and optimal design of spreads, allowing optimized footprint for maximal performance.

At Baker Hughes’ PPS, we hold a large spread of compressors, boosters, and membrane units, allowing extensive reliability and control of the operations, especially in remote areas, all over the world.

Our Baker Hughes’ PPS DENIZEN™ coiled tubing downline system (CTS) was designed to overcome the shortfalls of the traditional downline methods. CTS is typically used for subsea pipeline dewatering and fluid injection. The deployment of the skid and over boarding structure have been specifically developed for pipeline pre-commissioning applications. Key benefits of using CTS compared to classic downline are:

- delivery time of the coils and ease of having contingency

- smaller footprint on deck

- higher reliability

- more efficient mobilization and transport

At Baker Hughes’ PPS, we offer a comprehensive alternative to the large equipment spreads that are typically required for deep water pre-commissioning. Optimize your project budget with our patented DENIZEN™ Subsea System, while minimizing weather-related delays, reducing the project carbon footprint and enhancing personnel safety. The technologies we employ on the subsea systems are mature, reliable, and complemented by an experienced team of technicians and engineers who see each project through, from concept to execution. From flooding to hydrotesting and subsequent dewatering,

Umbilical lines are the lifeblood of subsea developments. Delays, repair, or rework processes can be expensive and time consuming. That’s why verifying the condition of the umbilical through testing and monitoring is critical to mitigating risks and costs. At Baker Hughes’ PPS, we provides complete turnkey services for pre-commissioning and commissioning umbilical systems from load-out at the manufacturing facility, through installation, to product introduction and start up. Our objective expertise and unmatched experience ensure cleanliness and integrity while verifying that the lines conform to your predefined specifications.

At Baker Hughes’ PPS, we have a long history of providing nitrogen services. With our fleet of nitrogen pumps, liquid nitrogen transports, mobile liquid nitrogen storage units and nitrogen membrane units dedicated to the midstream and downstream sectors, we are able to handle any nitrogen service project.

As the world shifts toward a low-carbon future, existing energy infrastructure is being reimagined to support emerging technologies.

One of the most promising strategies is the repurposing of liquid hydrocarbons and natural gas pipelines for the transportation of hydrogen (H₂) and carbon dioxide (CO₂), both critical components in the decarbonization of industry and energy systems.

In addition to our in line inspection (link) capabilities, Baker Hughes PPS supports operators with their network evolution. A lot of technologies and equipment are common with our pipeline pre-commissioning and maintenance experiences, ensuring teams readiness.

More specifically, we can provide information and assessments at early stage of the projects – especially on the most critical parts of the repurposing which are:

- for H₂ pipelines: decommissioning solutions (e.g. gas evacuation with mobile compression units onshore), and cleaning. Offshore applications

- for CO₂ pipelines: deep cleaning methodology, dewatering and drying. Study of possibility of dry pre-commissioning activities

Pipeline maintenance

Pipeline maintenance services enable your pipelines to operate at maximum efficiency by keeping them clean and reducing downtime during offline periods. Our team has knowledge and capabilities to design and perform cleaning and testing protocols but will also be a partner of choice in case of emergency. As an example, we’ll keep your pipeline flowing if a pump breaks or during repairs, or we can provide mobile gas compression equipment during pipeline blowdown, or modification exercises, which can help maintaining a gas flow or pressure and reduce methane emissions. . Our large inventory of equipment helps to reduce downtime and costs, and if you’re unsure on the best cleaning program of a pipeline we’ll be able to provide an assessment and dimension technical solutions.

When repairs are needed, our experts in pipeline decommissioning, including de-inventory and nitrogen purging, will collaborate with you to safely prepare for hot work. Before the line goes back into service, hydrotest can be performed to confirm line integrity and dried it to your specified dewpoint, so your product meets specifications.

The typical industry solution for pipeline maintenance services involves engaging multiple suppliers, with the risk of a lack of coordination around mobilization and demobilization windows. The integrated Baker Hughes’ PPS solution brings all these activities together under a single project management team. For mutual goal–safe operations, asset integrity, and enhanced profitability.

Our mechanical, chemical, and gel cleaning methods allow us to match your pipeline conditions and help with cost efficient debris removal. We clean crude oil, refined products, water, natural gas, and specialized petrochemical pipelines, including difficult-to-treat ethylene systems without impacting product quality.

Recent growth in pipeline repurposing projects places deep cleaning capabilities among key topics, since this is a critical stage to ensure efficient drying. Our engineering team is available to review scopes and provide specifics deep cleaning and drying solutions.

Large scale CCUS (Carbon Capture Utilization and Storage), Hydrogen or Ammonia projects contribute to Green House Gas emissions reductions around the world. They often require pipeline networks to be adjusted and/or developed, essentially to transport CO2 or H2.

Our pipeline pre-commissioning activities will support any new pipeline, but often, reusing existing pipeline networks can lead to a more cost-efficient deployment. Requalification for these pipelines is needed to comply, similar to the requirements at the initial pipeline design stage, for CO2 or H2 transportation.

Baker Hughes’ PPS is the only company able to provide best in class service and equipment that will ensure first time right in-line inspection and off-line tool propulsion in one turnkey package. Intelligent pipeline inspections provide the most sophisticated data for the integrity of a pipeline system and, in conjunction with hydrostatic testing, are a fundamental part of safe operation. ILI tools are generally propelled with pipeline product; but occasionally, conditions exist where another medium is needed for propulsion. Learn more here.

Our decommissioning services support end of life for topside and subsea assets with a focus on environmental safety and regulatory compliance.

Specialized cleaning ensures the removal of residual hydrocarbons, along with sludge, debris and any other deposits from the internal surfaces of process and pipeline systems.

The provision of a clean and uncontaminated surface finish and the disposal of generated waste products using existing process and disposal routes are critical objectives during any decommissioning project.

Our decommissioning service areas of hydrocarbon freeing, system cleaning, filtration, separation and flaring provide a reduction in hazardous waste and associated disposal costs, while reducing risk to people and the environment.

Baker Hughes’ PPS’s environmental service offering delivers a track record of reducing the impact of carbon emissions associated with decommissioning activities.

At PPS, we specialize in mobile natural gas recompression—also known as mobile pipeline evacuation. Our units are designed to safely and efficiently transfer natural gas from a source location to a receiving area, such as a different pipeline segment or an adjacent pipeline.

Common Applications

Our services are commonly used for:

- Transferring gas between pipeline sections

- Evacuating gas into underground storage reservoirs

- Supporting intelligent pigging operations

- Managing pipeline pressure and gas flow conditions

We provide flexible solutions for any operation requiring precise gas control.

Key features of our mobile gas recompression services

- Dual expertise

We are both a service provider and a manufacturer of mobile gas evacuation systems. This unique combination allows us to deliver high-quality services that meet Oil & Gas HSE standards, backed by the technical expertise of an OEM. - Tailored equipment fleets

Our equipment is adapted to meet regional and operational needs. Our U.S. fleet, based in Houston, Texas, features different specifications from our European fleet, based in Eindhoven, Netherlands. - Large & small volume capabilities

We specialize in large-volume gas recompression—handling up to 22 million Nm³ (777 MMSCF) in a single operation. We are also expanding our capabilities to efficiently manage small and medium volumes, down to 10,000 Nm³ (350,000 SCF). - Integrated gas & nitrogen services

PPS is the only company offering both mobile gas transfer and nitrogen services. This enables maximum gas recovery and minimal emissions. - Custom solutions

If your project requires more than standard gas recompression, we can design and deliver fully customized solutions tailored to your specific needs.

We believe transparency around carbon footprint is essential. We provide both quantitative (kg CO₂e) and qualitative (Scope 1 and 3) data to help operators understand the environmental impact of their operations. Contact us to learn more.

Ready to optimize your gas operations?

Natural gas transfer can be efficiently controlled using nitrogen displacement, tailored to the specific characteristics of the system, whether a pipeline, network, or storage tank. Provided the nitrogen flow rate is managed correctly to minimize mixing, a physical separator (pig) would not be required.

We engineer optimized flow strategies to ensure effective gas displacement with minimal mixing between natural gas and nitrogen. Only the minimal natural gas/nitrogen mixture (typically less than 0.5% of the total pipeline volume) requires management through venting or flaring.

Typical applications include:

- Displacement of small to medium gas volumes (less than 60,000 Nm³ or 2.1 MMSCF)

- Situations requiring rapid on-site mobilization

- High-pressure discharge scenarios

Flaring can serve as an effective complement to gas recompression and nitrogen purging services in specific scenarios. When using high-efficiency flares (greater than 99% combustion efficiency), the resulting CO₂ emissions have a significantly lower environmental impact compared to methane.

Mobile flaring is a viable solution for handling small gas volumes or gas mixtures that cannot be recompressed or purged.

Share your application details with us, and we’ll identify the most suitable technical solution—typically a tailored combination of mobile gas compression, nitrogen services, and mobile flaring.

At Baker Hughes PPS, our high-efficiency gas recompression systems can reduce pipeline pressure to as low as 0.2 barg, minimizing residual gas. However, in large-diameter or long-distance pipelines, even this small pressure can represent a significant gas volume.

We offer a combined nitrogen displacement and gas recompression solution to further reduce emissions and enhance operational efficiency. This integrated approach:

- Minimizes natural gas emissions by displacing residual gas with a nitrogen/natural gas mix

- Maintains project timelines, as nitrogen flow enhances the performance of the gas booster

- Delivers a fully inert pipeline, ensuring safety and readiness for maintenance or decommissioning

Reduce Methane Emissions with Mobile Flaring and Gas Recompression Solutions

Methane has a significantly higher global warming potential than CO₂. That’s why, in certain scenarios we offer a combined solution using mobile gas recompression, nitrogen displacement, and mobile flaring to manage large volumes of residual gas—particularly the nitrogen/natural gas mix.

This approach is especially effective when transferring gas from large-diameter or long-distance pipelines, where residual volumes can be substantial.

Our turnkey service ensures:

- Minimized environmental impact

- Maximized operational efficiency

- Optimized project costs

Contact us to learn how we can tailor a solution to your pipeline gas recovery and emissions reduction needs.