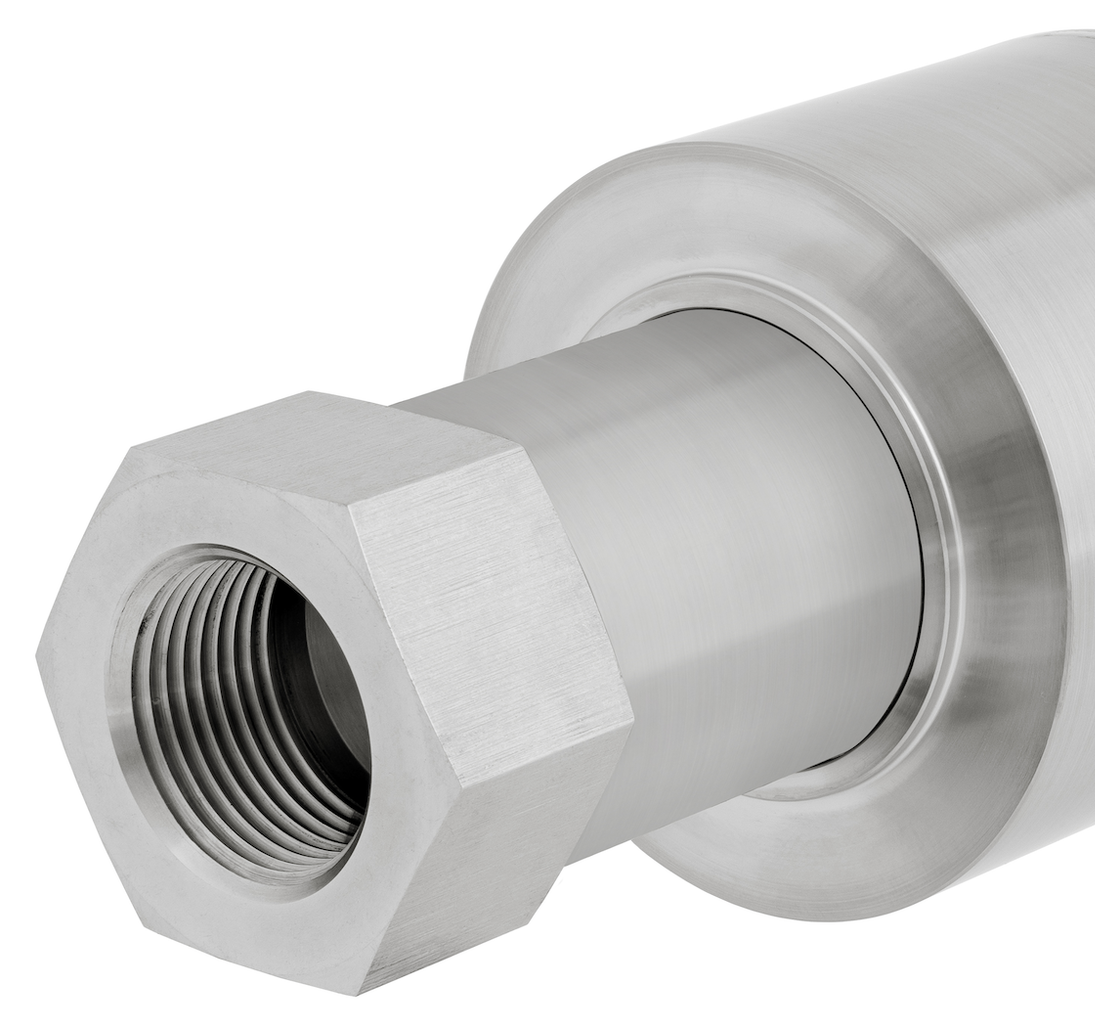

Rugged, Reliable Flame Sensing Technology

Our sensors operate up to

120°, 150°, or 325°

Celsius

A ready solution for

HARSH ENVIRONMENTS

Reuter-Stokes burner application flame sensor solutions provide reliable flame supervision in extreme conditions.

Built on technology with over

500 million

Operating hours

Find Your Solutions

Certifications & Regulatory Compliance

All Reuter-Stokes flame sensors are hazardous area certified.

- Class I Division 2 and Zone 2 models for Power Generation market

- Class I Division 1 and Zone 1 models for Oil and Gas market

Certifications include North American, ATEX, and IECEx as well as multiple country specific certifications.

Select Reuter-Stokes sensors are capable of SIL 3 operation, Exida certified.