How an innovative test well and a technology consortium are working to help transition oil and gas companies towards baseload geothermal energy.

What if you could take a decommissioned oil or gas well and use the existing infrastructure to turn it into a closed-loop geothermal well capable of producing baseload power?

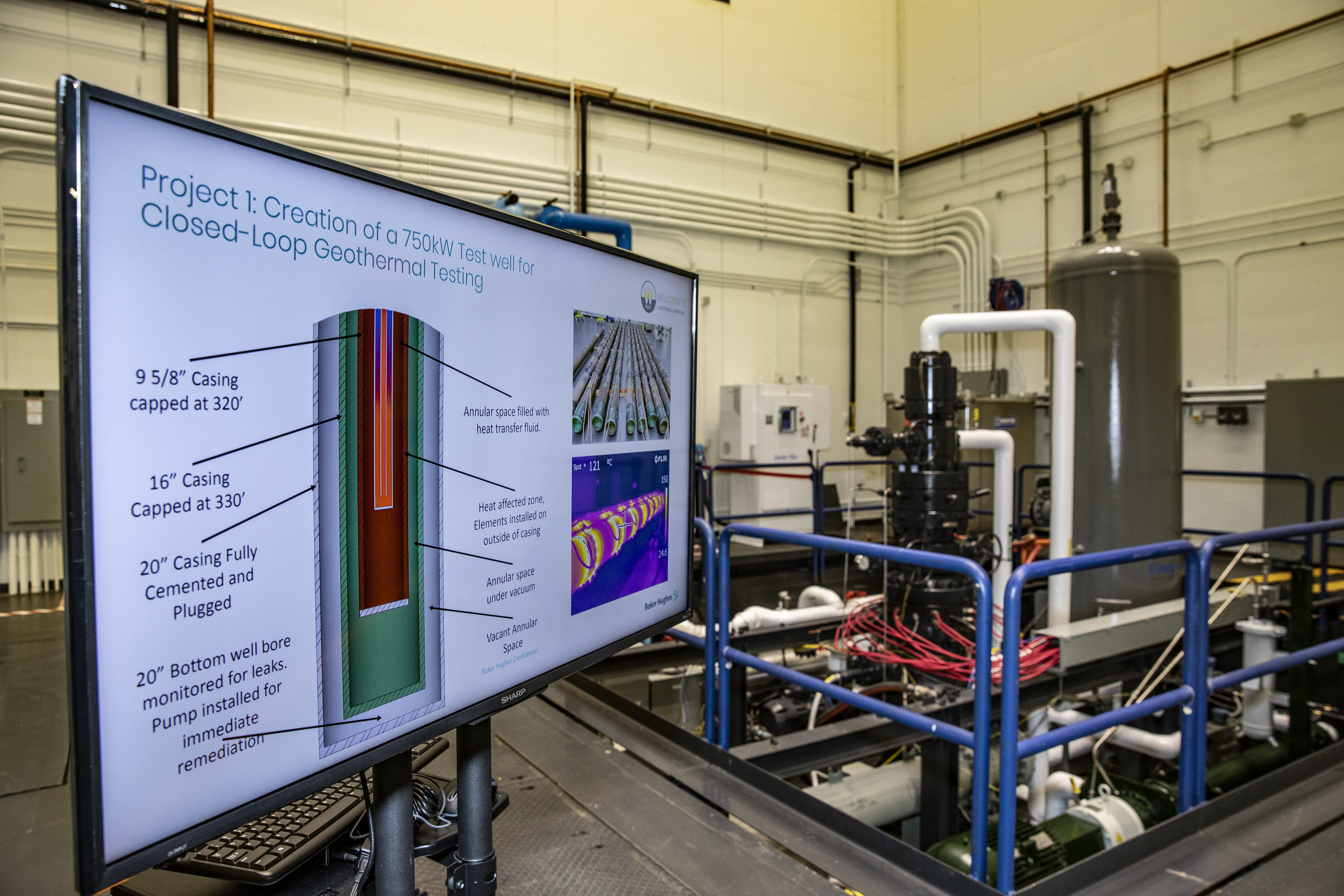

That’s exactly what the Wells2Watts geothermal energy consortium is actively exploring at the new test-well facility at the Baker Hughes Energy Innovation Center in Oklahoma City. The closed-loop test well inside the center – part of the Hamm Institute for American Energy – was commissioned in October 2023 and the results from early tests are now being analyzed by consortium partners.

“Our pure-play independent oil and gas customers see geothermal as an opportunity to reduce carbon emissions in their own operations and also to help with other companies’ net-zero strategies,” says Rob Klenner, Director of Geothermal Technology and Innovation with Baker Hughes and executive director of the Wells2Watts consortium.

The consortium was formed at the end of 2022 and has four operators – Continental Resources, INPEX, Chesapeake Energy and California Resources Corporation – now on board. Wells2Watts is using the test well to accelerate the development of technologies that can help scale geothermal to supply baseload energy, an important step forward in the energy transition.

“At the test well here in Oklahoma City we can test new geothermal technologies and also test how customers can use their existing infrastructure,” says Klenner. “For example, where they’ve drilled oil and gas wells with high temperatures – that available heat could be used for geothermal. The idea is that they can transition an oil and gas well that’s no longer producing and become a renewable energy producer.”

First, heat your pipes

The closed-loop test well accurately simulates subsurface environments and different configurations to validate engineering models to inform the next step when those learnings will be taken out to the field for pilot studies. Initial testing has used GreenFire Energy’s GreenLoop™ technology (Baker Hughes is an investor in the company), and ICE Thermal Harvesting’s heat-to-power system.

“The easiest way to think about the test well is that it’s a 300-foot-deep hot hole that we can control,” says Jason Angolano, Laboratory Manager at the Baker Hughes Innovation Center. “The inner bore is the inside of a 9-inch pipe, which can be heated to 450℉, which allows us to mimic a geothermal well.”

The energy to heat the geothermal test well is from the grid – and it’s a large load. “We have 90 electric heaters coiled around the pipe – grouted to it every three feet – and each one of those heaters draws roughly 8.4 kilowatts. By heating the pipe from the outside, we can accurately control it and demonstrate how sub-surface technologies operate at those high temperatures and pressures for closed-loop geothermal. Of course, the 300-foot wellbore is the test scale – normally it would be thousands of feet of wellbore, but it does allow us to mimic that section of a geothermal well.”

In addition to measuring and monitoring the performance of technologies as they’re demonstrated in the wellbore, the team is also interested in testing uses for the process fluid. “We can test ways using the output of the geothermal well for such things as heat to power, which is where the Wells2Watts moniker comes from,” adds Angolano.

The birth of new businesses using tried and tested technologies

Wells2Watts invites tech partners with novel geothermal technologies to join the R&D train at the Oklahoma City test well. Long-time Baker Hughes vendor Vallourec (which is also an investor in GreenFire Energy) was eager to take one of its key products down the well. The French-headquartered multinational has been making steel pipe and mechanical connections for the oil and gas sector for over 140 years.

Just as their customers are transitioning their operations to decarbonize, so is Vallourec. “In 2021 I was tasked with creating a new business line for Vallourec in North America, looking only at non-fossil energy opportunities under three main pillars: carbon capture, hydrogen and geothermal,” says Joe Hill, Vice President of New Energies North America at Vallourec.

“Vallourec has vacuum-insulated tubing which is perfect for geothermal applications and is our in-kind contribution for Wells2Watts,” says Hill. “Imagine vacuum-insulated tubing (VIT) as a ‘yeti’ cup – it’s keeping hot stuff hot and cold stuff cold. We pump cold water down one side of the tube and it heats up at the bottom of the well, producing hot water up the other side. Our insulated tube makes the geothermal well more efficient because it’s keeping the maximum amount of energy trapped in that working fluid all the way up to the surface. The issue with geothermal is that at the bottom of the resource the water is hot, but it loses energy as it rises towards the top. Our product – THERMOCASE® VIT – almost completely eliminates heat loss from the bottom of the hole all the way to the surface.”

Being able to demonstrate this in the test well is critical, Hill explains, because to date much of the proof-of-concept work around closed-loop geothermal has been computer modeling. “This test well is a one-of-a-kind facility that can prove out modeled technology and help us to advance closed-loop geothermal. Wells2Watts gives us the opportunity to say, ‘We can model it and then we can test it and if those things line up then it’s easier for consortium members to put money for an in-field project.”

Pursuing a common goal

Knowing that emerging energy technologies need support as they refine techniques and gain market traction, Hill says Vallourec wants to be more than a vendor and be a true partner for closed-loop geothermal projects.

“We don’t want it to be a matter of an operator saying, ‘I have a 10,000-foot well’, and we say, ‘Fine, here’s 10,000 feet of our VIT’,” says Hill. “We are going to engineer what makes sense for the project. As we’ve already discussed with Baker Hughes and other consortium members, there’s no need to take the VIT all the way to the bottom, where it’s already hot. You can use mono-bore tubes to a certain length and then transition to VIT where you start losing heat to the formation. We’ve had customers wanting everything from two kilometers to 10 kilometers of VIT and we work project by project and customer by customer.”

As THERMOCASE® VIT comes into play for renewables it’s clear that it is both an enduring and extremely adaptable technology – it was designed for offshore drilling almost 40 years ago.

Vallourec manufactures all its VIT in the USA. “All THERMOCASE® VIT is made at our manufacturing site in Houma, Louisiana. The mother tubes for Wells2Watts were produced in our steel-making facility in Youngstown, Ohio, then shipped to Louisiana for fabrication and then trucked to Oklahoma City.”

Hill sees huge potential in closed-loop geothermal as a renewable energy source and is happy to be demonstrating Vallourec’s product in the test well. “For us, Wells2Watts is about advancing and accelerating geothermal technologies,” he says. “If you have a dormant or underperforming oil or gas well that you would normally plug and abandon and now through geothermal you can turn it into energy, that’s a good story. It’s very important to us and we’re very excited to move to phase two of Wells2Watts.”

Moving swiftly into the field

The first field pilot for the Wells2Watt consortium is likely to go ahead later in 2024 with consortium partner California Resources Corporation (CRC).

“CRC’s Carbon TerraVault (CTV) business is a carbon capture and sequestration (CCS) business,” explains Chris Gould, Executive Vice President and Chief Sustainability Officer at CRC, and Managing Director of CTV Holdings. “We’re utilizing the skills and knowledge base of our employees who were previously extracting hydrocarbons to now injecting CO2 into depleted reservoirs to permanently store it away. Our interest in Wells2Watts is the possibility to repurpose our wellbores and depleted reservoirs to obtain geothermal energy.”

CRC and CTV are aligned with California’s goal to be carbon neutral by 2045, five years earlier than the Paris Agreement. “Our state has a sense of urgency around energy transition and carbon management, and geothermal energy will both play an important role,” says Gould. “CRC has the assets and skills for valuable renewable energy and carbon management activities.”

Gould says they are very conscious of the ticking clock to 2045. “Being a smaller company, our focus is on projects with tangible impact in the near term,” he says. “That lends itself to opportunities where we can get off the modeling track and onto the demonstration and implementation track. A test well where we can prove this technology out is very attractive!”

CRC has a field outside of Bakersfield in California that is seen as ideal for the first pilot outside of the test well in Oklahoma City. “It will be a demonstration project for heat recovery by repurposing the well,” says Gould. “Once the early work at the test well is wrapped up, we’re very open to providing the opportunity for field testing.”

If the demonstration project with CRC goes well, Gould says it “certainly could” become a live operation. It’s early days of course, but if you could bottle the enthusiasm of the Wells2Watts members you’d have a powerful energy source right there.

“This international consortium is a partnership with our customers, and we love that we’re able to work so closely with them and hear their needs,” says Angolano, “It’s been a journey of learning for everybody as we go deep to understand geothermal a lot better. Getting that understanding of how they can bring geothermal into their portfolios is what’s important to them.”

Sign up now

Subscribe to stay up to date on the latest innovations and people shaping the future of our industry.