Overview

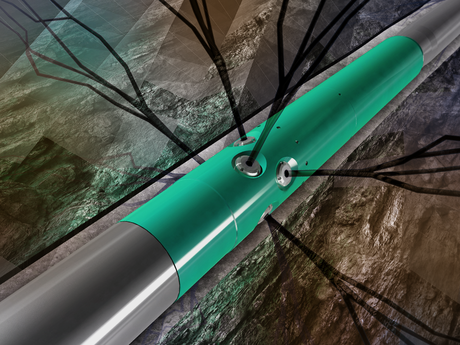

Reduce overall pumping time with quick, continuous hydraulic fracturing using our FracPoint™ ball-activated multistage fracturing system. The FracPoint portfolio contains single-entry and multiple-entry sleeve options for cemented and openhole applications.

After the system has been installed, stages are isolated using openhole packers or cement. The sleeves are then activated, using various-sized frac balls dropped from the surface as the fracturing treatment is pumped, providing nonstop fracturing operations. After fracturing is complete, production can begin immediately, and our IN-Tallic™ disintegrating frac balls disintegrate in the well to ensure a clear flow path without through-tubing intervention.

Create cluster perforations with multiple-entry sleeves

FracPoint multi-point (MP) sleeves mimic the cluster perforations of a plug-and-perf completion, but require 50% less fracturing time. The MP sleeves use graduated balls and ball seats to open up to five sleeves per stage with a single frac ball for increased efficiency.

Achieve precise placement with single-entry sleeves

FracPoint single-entry sleeves enable precision placement of fracture treatments along the wellbore. Successively sized ball seats correspond to different-sized IN-Tallic frac balls, enabling the sequential treatment of individual stages. As each stage is fractured, the ball for the next stage is dropped. Once the ball lands on seat, a set amount of pressure opens the sleeve and that stage is fractured.

To enable maximum efficiency and optimized frac cycle times at all lateral depths, FracPoint sleeves can be combined with the OptiPort frac system, as well as composite and dissolvable frac plugs.