Highlights

Benefits

- Proven component choices for Life of field configuration

- Enables use of efficient flow management solutions on differing well needs

- Provides choices for individual component or combined replaceability of light module

- Improved reservoir management opportunities and fiscal monitoring of individual well flow

Applications

- Subsea tree or manifolds placement

- Production or injection applications suitable for a range of flow media

- Suitable for electro hydraulic or all electric operations

- Shallow to deepwater applications in a single design

Overview

With multiple choices on individual development needs, Baker Hughes can provide alternatives to suit the optimum solution for each project development.

Such arrangements include options of

- Individual item recovery such as Choke Inserts,

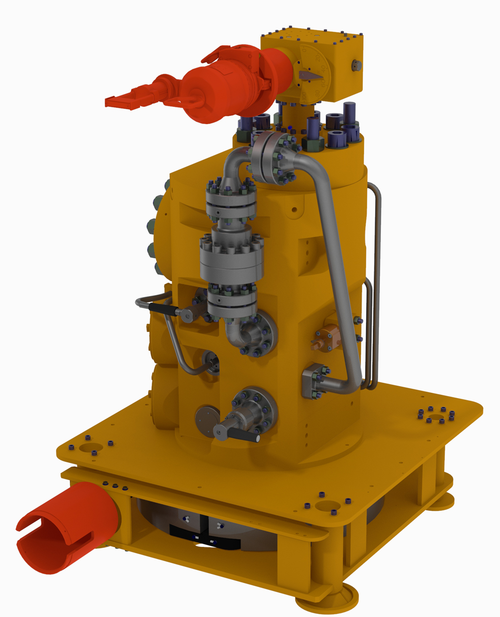

- Flow Control Module (FCM) configured with multiple items, recoverable simultaneously,

- Integrated Process Module (IPM) with combined multiple features.

In its simplest form, the items retrieved individually provides a simple solution with easy replacement without disrupting other Tree functionality but may require multiple interventions for differing components increasing operating cost.

The use of a flow control module provides perhaps simpler intervention activities through the ability to recover and replace multiple items in a single intervention. This provides the comfort that the field life has been extended without further intervention mobilisation to address another component. Accompanying the benefits is however a slightly increased capital cost due to incorporating the multiple individual parts, the fabricated Flowpath between the parts, the larger retrievable structure and its impact on the wider Tree arrangement.

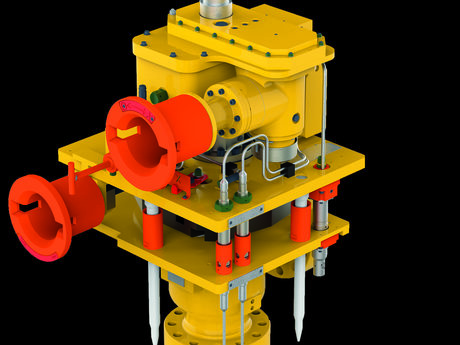

The Integrated Process Module provides a cost-effective simplified solution of combining multiple features and functions seen in Flow Control Modules into a single retrievable assembly enabling significant weight and size reductions over that of Flow Control Modules and paired with simple retrieval and the smaller envelope also eases tree system structure size, weight and installation.

Developed through a collaboration between Emerson's Roxar™ Wet Gas Flow Meter Technology and Baker Hughes' Electric Choke, the Integrated Process Module brings a new level of efficiency and convenience to the industry with reductions of 40% in weight and 50% in size over typical flow control modules, the IPM enables greater operational flexibility for installation, safety, and reliability.

IPM

The IPM's compact design and enhanced functionality make it a game-changer for subsea operations reducing the overall footprint of subsea installations, leading to more cost-effective projects, faster deployment, and increased operational efficiency.

Developed through a collaboration between Emerson's Roxar™ Wet Gas Flow Meter Technology and Baker Hughes Choke, the Integrated Process Module brings a new level of efficiency and convenience.

With a simplified design, the IPM requires fewer components, eliminates any special tooling needs during intervention subsea. This breakthrough feature not only saves valuable time and resources but also enhances operational safety and reliability.

Choke

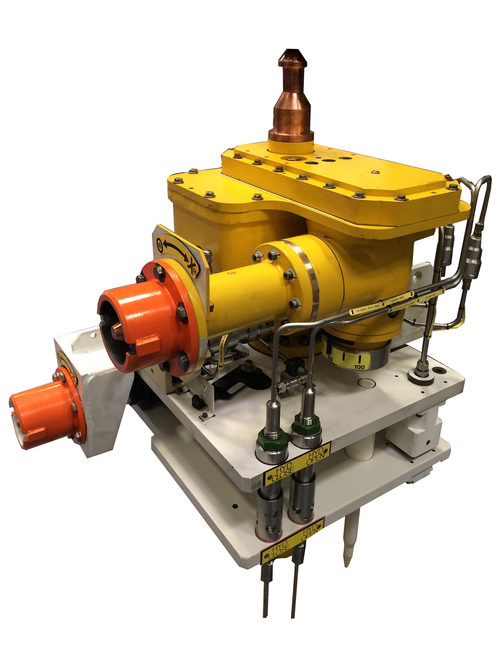

The FaStep Hydraulic Stepping Choke has been designed and qualified to exceed industry standards with endurance testing to more than two million steps, fast actuation of upto 30% greater than that of other industry products and coupled with superior controllability stepping resolution that provides enhanced reservoir management.

Comprising a single-stage High Friction HF-LCV design, our ‘plug and cage’ trim design has been used successfully on debris/sandy service applications –This proven trim technology controls the flow, minimizes erosion, vibration and noise within the system. For water injection applications, a multi-stage trim can be provided to mitigate the onset of cavitation.

The valve actuator consists of a core gearbox with a proven high-integrity ‘ratchet and pawl’ design and pulsed/ stepped hydraulic cylinders that provide the motive power with a configurable over-ride solution within the choke.

Engineered in nominal 2", 5" or 7" sizes to operate in up to 10,000 ft (3,048 m), with pressures of up to 10,000 psi and temperatures between -51°F to 350°F (-46°C to 177°C), using proven materials for reliability and longevity.