Determine the image quality of digital radiography (MTF and DQE)?

Image quality is the total result of resolution, contrast and noise.

Conventional X-ray films exhibit an extreme high intrinsic resolution due to the fine granularity of the radiation sensitive crystals (a few microns). The resolution of the resulting image is far better than the human eye can resolve. Hence the use of IQIs for film is an adequate measure of resolution and image quality which meets the qualification needs of industry. As such there is no need for any additional resolving criteria. However, for digital radiography with a much lower intrinsic resolution (typical 100 micron or less) a different situation exists. To select or purchase the proper digital system, information which quantifies the resolving power of a digital system is needed. Although generic methods to measure optical resolution do exist, they are not yet specified for digital radiographic systems.

To fulfil the need for a qualification of resolution, prior to anticipated release of future standards, suppliers of digital radiography systems already use methods and definitions which are common in other sciences. Resolution is defined as the smallest separation (distance) between two objects that the human eye can distinguish. Because the human eye is not easily quantifiable, an objective method to indicate resolution is needed. Resolution is dependent on contrast

(grey levels) and separation (distance).

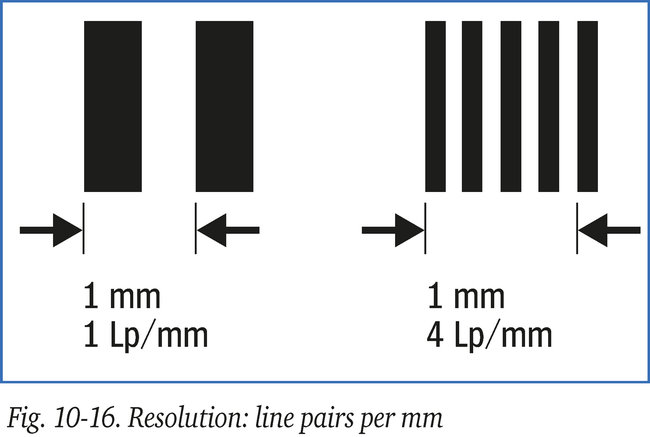

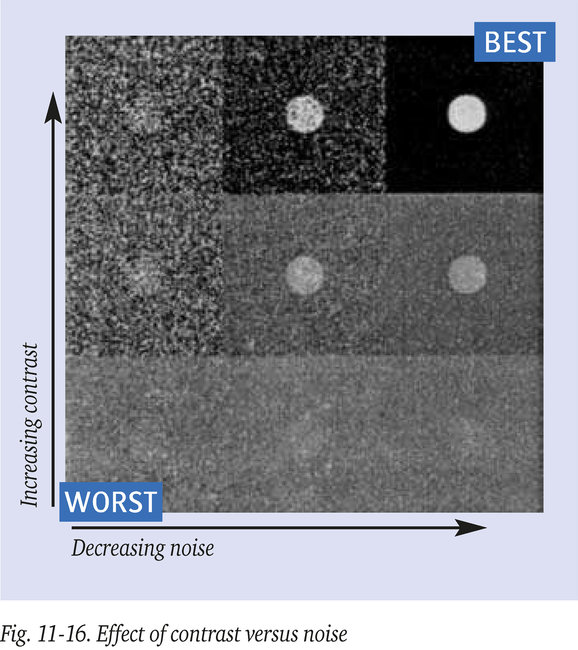

Resolution is expressed as the number of lines that can be distinguished in one mm, see figure 10-16. The scientific measure to quantify the mutual effect of distance and contrast on resolution is the “Modulation Transfer Function”, for short MTF. Each component in an imaging chain has an individual MTF. The MTF of a whole system, is the product of the MTF’s of the individual components. By measuring MTF, a relative value ranging from 0 to 1 (or 0 to 100 %) , the resolving capability of a system is given. This characteristic value is typical for a system. This means that flaws will be more easily visible at a higher MTF. A system should have an MTF that matches the MTF associated with the most demanding application. However the quality of a digital image is not only determined by the systems MTF-value but also by the exposure conditions. Exposure conditions such as thickness of the object, focal spot and source to film distance

influence geometric unsharpness (blur) as well as contrast and noise of the system and image, see figure 11-16. Therefore the definition of “Detective Quantum Efficiency”, for short DQE, has been introduced. The DQE value, is a mathematical expression indicating the overall aspects of image quality and is a combination of MTF, sensitivity and noise:

DQE ≈ Image quality / Dose

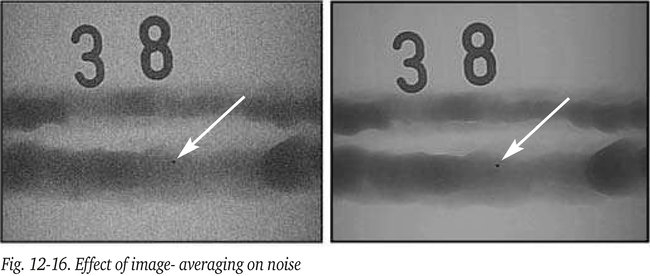

Noise in turn depends on speed, thus the time needed for an exposure to create an image which might include signal averaging to achieve the required image quality. Reduction of noise by averaging the signals from a number of exposures increases the image quality considerably as illustrated by the images of figures 11-16 and 12-16. Unfortunately signal averaging in turn lowers the DQE proportionally due to increased exposure time.

In general, the DQE-value consolidates the plate- or panel performance of many individual parameters (resolution, efficiency/exposure time, noise etc.) in a single number. DQE value

ranges from 0.0 to 1.0, numbers in practice differ from 0.05 to 0.9.

In summary: MTF quantifies the performance of the plate or panel, DQE quantifies the overall performance, thus MTF of plate or panel including the exposure itself. In other words: DQE quantifies the ability of a detector to accurately provide the information present in the X- or gamma rays including the imaging process. Thus the DQE value

indicates the final image quality and the inspection time required for a given application.

Remark: Despite the efforts to introduce MTF and DQE in the NDT industry - a value which for the actual users of CR and DR is rather abstract and hard to comprehend - in practice the IQI is still (in 2006) the only indicator of image quality. Almost always the duplex IQI is

applied for CR and DR. The duplex IQI consists of sets of two metal wires close together