What are common image quality indicators (IQIs)?

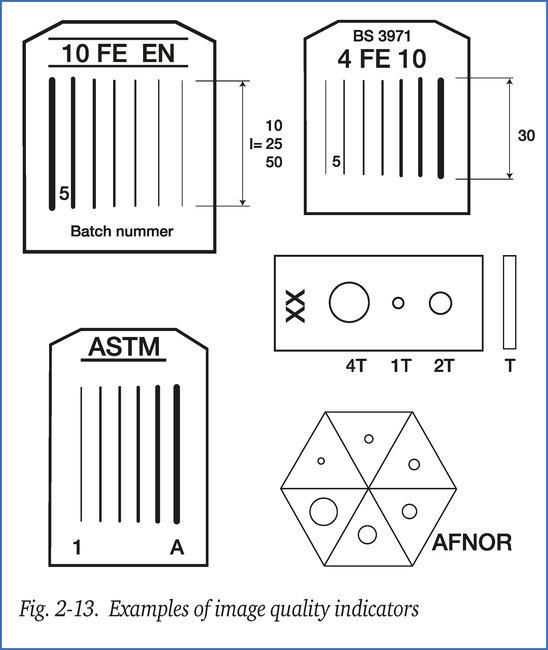

Figure 2-13 shows the five most common IQIs. Their origin and description can be found in the following standards:

- EN 462-01 Europe

- BS 3971 Great Britain

- ASTM 747 USA

- ASTM 1025 USA

- AFNOR NF A 04-304 France

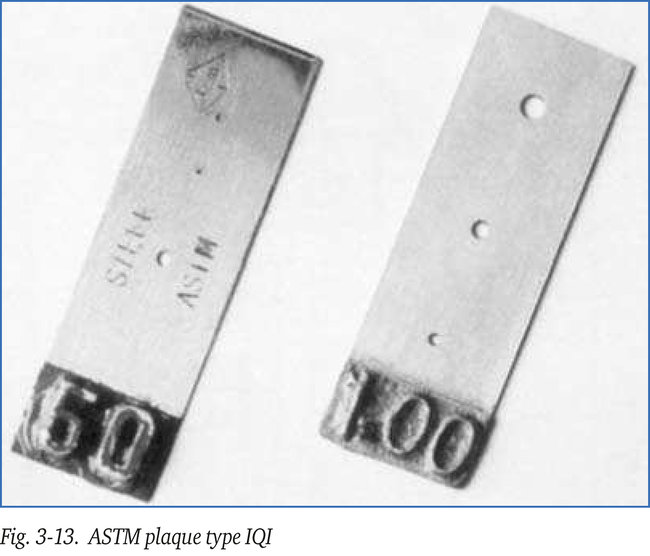

American IQIs

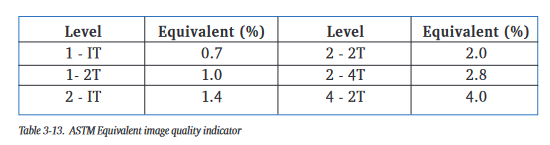

The plaques have markings showing their thickness in thousandths of an inch. Each plaque has three holes of diameters 1T, 2T and 4T. T being the thickness of the plaque. Thin plaques with T < 0.01” form an exception to this rule. Hole diameters for these plaques are always 0.01”, 0.02” and 0.04”, so do not comply with the 1T, 2T, 4T rule. These types of plaque are identifiable through notches cut in the edge, by which they can also be identified on the radiograph. Originally it was standard practice to use a plate of 2 % of the specimen thickness, but at present 1 % and 4 % plates are used too. If T is 2 % of the specimen thickness and the 2T hole can be seen on the radiograph, the attained sensitivity level is said to be (2-2T), etc. Equivalent sensitivity values in percentages are shown in table 3-13. At least three sides of a penetrameter must be visible on the radiograph. The thickness of the penetrameter in relation to the specimen thickness defines the “contrast sensitivity”. The size of the smallest hole visible defines the “detail sensitivity”.

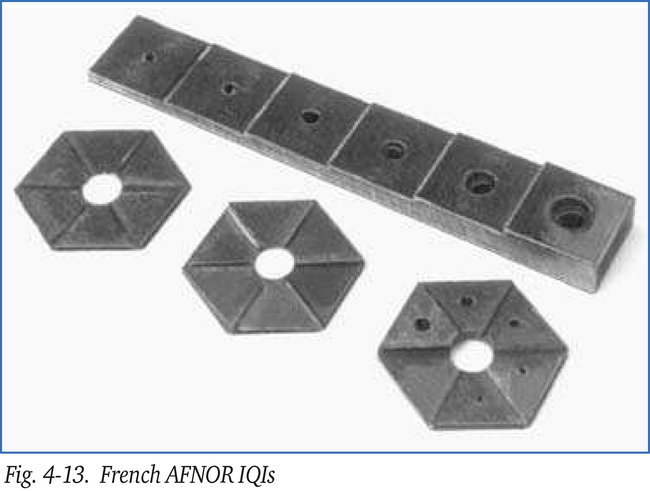

French IQIs

The AFNOR-type IQIs originate in France. They consist of metal step wedges of the same material as the object to be examined. The thickness of the steps increases in arithmetical progression. Each step has one or more holes with a diameter equal to the thickness of that step. There are various models of step wedges. The most common types are rectangular with square steps measuring 15x15 mm and hexagonal with triangular steps measuring 14mm. See figure 4-13. Steps thinner than 0.8 mm, have two holes of the same diameter. For a step to be regarded as visible, all the holes in that particular step must be clearly seen on the film. The French standard AFNOR NF A04.304 includes an addendum, which defines the “index of visibility”. For each radiograph a record is made of:

1. the number of visible holes (a)

2. the number of holes (b) of a diameter equal to or greater than 5 % of the material

thickness being radiographed.

The index of visibility N is given by the formula: N = a-b. The value of N may be positive, zero or negative. Image quality improves as the value of N increases.

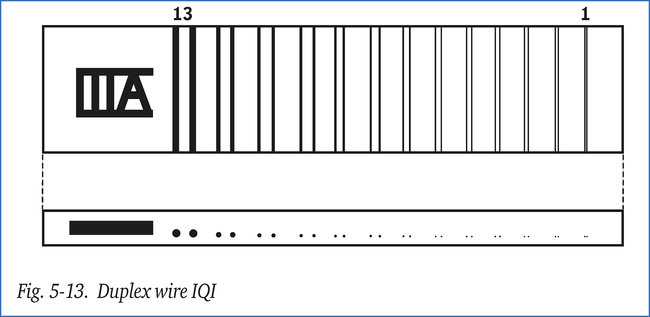

Duplex IQIs

The duplex IQI consists of a number of pairs (“duplex”) of wires or thin strips made of platinum or tungsten, of increasingly smaller size and diminishing distances for each pair. Figure 5-13 shows such an IQI made up of pairs of wires. The duplex IQI has been in existence for decades but is no longer current in conventional film radiography because of their high cost and limited possibilities of application. It is, however, increasingly used in digital radiography, because it is perfectly suited to determine contrast and (un)sharpness.