High-Resolution Computed Tomography (CT)

For medical diagnostic purposes, techniques have been developed to obtain a radiographic image with a resolution of approx. 0.5 mm. Powerful computers are used to transform all absorption variations that occur when irradiating with a moving source, into a comprehensive image. The technique is now also used in industry, e.g. for checking miniature electronic circuits as built into mobile telephones. Systems with a resolution of only a few micrometers have already been successfully applied.

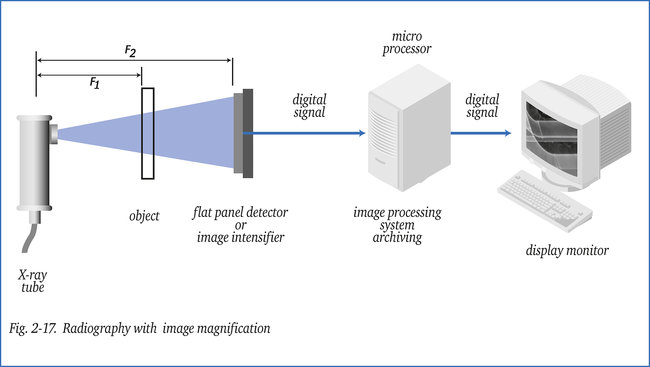

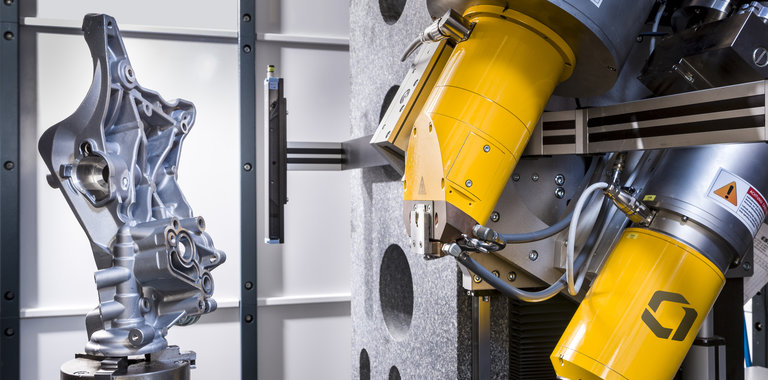

In the arrangement shown in figure 2-17, now the object to be checked rotates (continuously or stepwise by a robot) to obtain a CT-image. The object is scanned section by section with a very narrow beam of radiation (X- or gamma-ray). The receiver in this case is a flat panel detector.

Each individual detector element measures, during a short exposure period, the total absorption across a certain sectional plane of the object. A large amount of data has to be stored and processed, in particular when an image of high resolution is required. A three-dimensional representation (3D-CT) of the radiographic image requires vast computing capacity.

In CT, absorption values are determined with a very high degree of accuracy, which means that the contrast of an image can be varied over a extraordinary wide range. Absorption/density variations of 0.02 % can be displayed in a range of density 6 and over. This offers great possibilities for image processing.

With present day computers, depending on resolution required, the reconstruction-time of a 3D-image runs from 2 to 60 minutes. Increasingly, 3D-CT is used on high-quality castings, even with the extra facility of automatic object and defect identification. The subject of CT

is more elaborately described in the booklets (German) “Die Röntgenprüfung” and (English) “The X-ray Inspection”.

To analyse defects, 3D-CT systems exist which are able to accurately size random oriented cracks or other (planar) defects with a width of only > 25 micron. Such a system can be used to evaluate (flaws detected with other methods) in for example austenitic welds

(e.g. nuclear components) a task almost impossible to perform with ultrasonics.