Identify, analyze and prioritize resources for effective defect elimination

Cordant™ Asset Defect Elimination is a system used to identify cause and effect relationships for a defined problem, event or incident. This effective causal identification is critical to generating effective solutions and thereby solving recurring or systemic problems and eliminating defects across the enterprise. Cordant™ Asset Defect Elimination manages the process of defect/problem prioritization and analysis triggers. The tool is used to conduct analysis with a scalable depth of analysis based on severity of the problem, develop effective solutions, track progress and implement outcomes, leverage effective solutions across entire organizations where applicable.

Problem Analysis and Prioritization

Support all levels of analysis from the simple to more complex quantified analysis within one environment. Enables flexible and bulk data analysis. Supporting multiple methodologies, you can apply the right level of analysis to suit the defect or problem based on custom triggers.

Connect Solutions to Strategy in EAM Systems

Enrich your reliability analysis and strategy development. Get the benefit of a seamless connection between defect elimination action and solution tracking with EAM systems, where work requests are required. Extract and analyze relevant EAM data where required to support analysis.

Connected for data-driven continuous improvement

Cordant™ Asset Defect Elimination integrates with Asset Strategy Management and Asset Health for full circle asset performance management that prioritizes business objectives and drives digital transformation.

The Evolution of Asset Defect Elimination

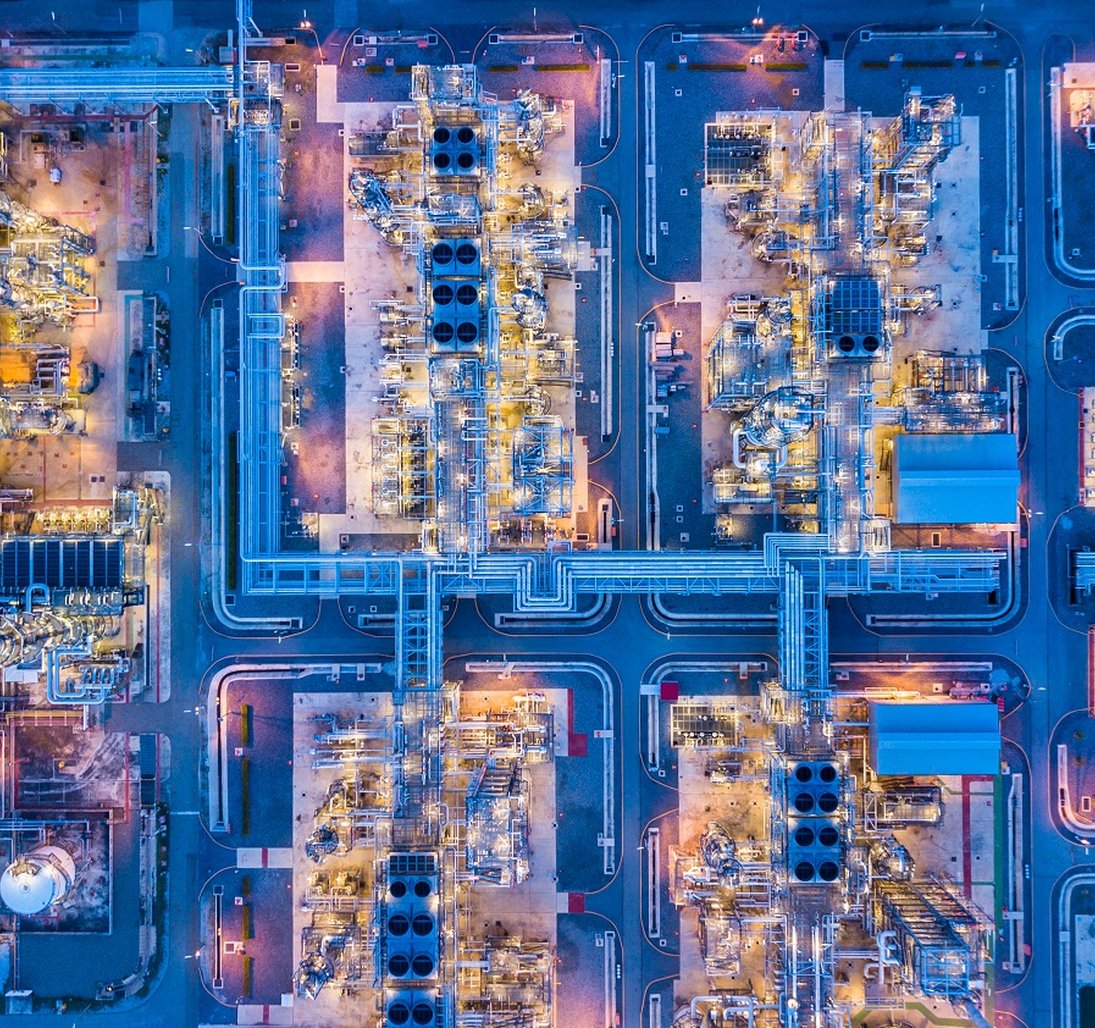

Asset-intensive industries like mining, energy, and utilities are under increasing pressure to reduce costs, mitigate risks, and adapt to workforce shortages and market volatility. Traditional asset management approaches are no longer enough to stay competitive. Discover how integrating data, AI, and automation across your asset management ecosystem can drive efficiency, improve decision-making, and create a sustainable competitive advantage.

A 360° view of assets drives continuous improvement

How Cordant™ Asset Defect Elimination helps

Effectively analyze problems to mitigate risk

Cordant™ Asset Defect Elimination enables flexible and bulk data analysis. Supporting multiple methodologies, you can apply the right level of analysis to suit the defect or problem.

- supports multiple methodologies

- store evidence

- benchmark causal categories

Leverage learnings and connect to reliability strategy

Using one system to capture and manage all analysis, learnings, solutions, and implementation enables learnings to be applied to all sites and departments. This is further supported by a data model that codifies the language used for causal analysis and allows this to be tagged to specific assets while driving system cause prioritization.

Prioritize and classify defects enterprise-wide

Defects and resolutions can be prioritized based on business exposure and benefit, and level of effort can be determined based on severity and problem types. Ensures focused effort, traceability of solution implementation and high ROI.

News and Resources

Case Study: Standardizing RCA

Global chemical company standardizes RCA across more than 40 sites