Real-time data to detect abnormalities and potential faults

In asset-intensive industries, condition monitoring sensors enable organizations to monitor equipment in real-time. By monitoring the condition of assets, companies can detect failure patterns, predict breakdowns, and optimize maintenance, thereby shifting from ineffective, reactive maintenance to more proactive and predictive approaches. Resulting in reduced downtime. Improved safety. Effective management of risk within their operations.

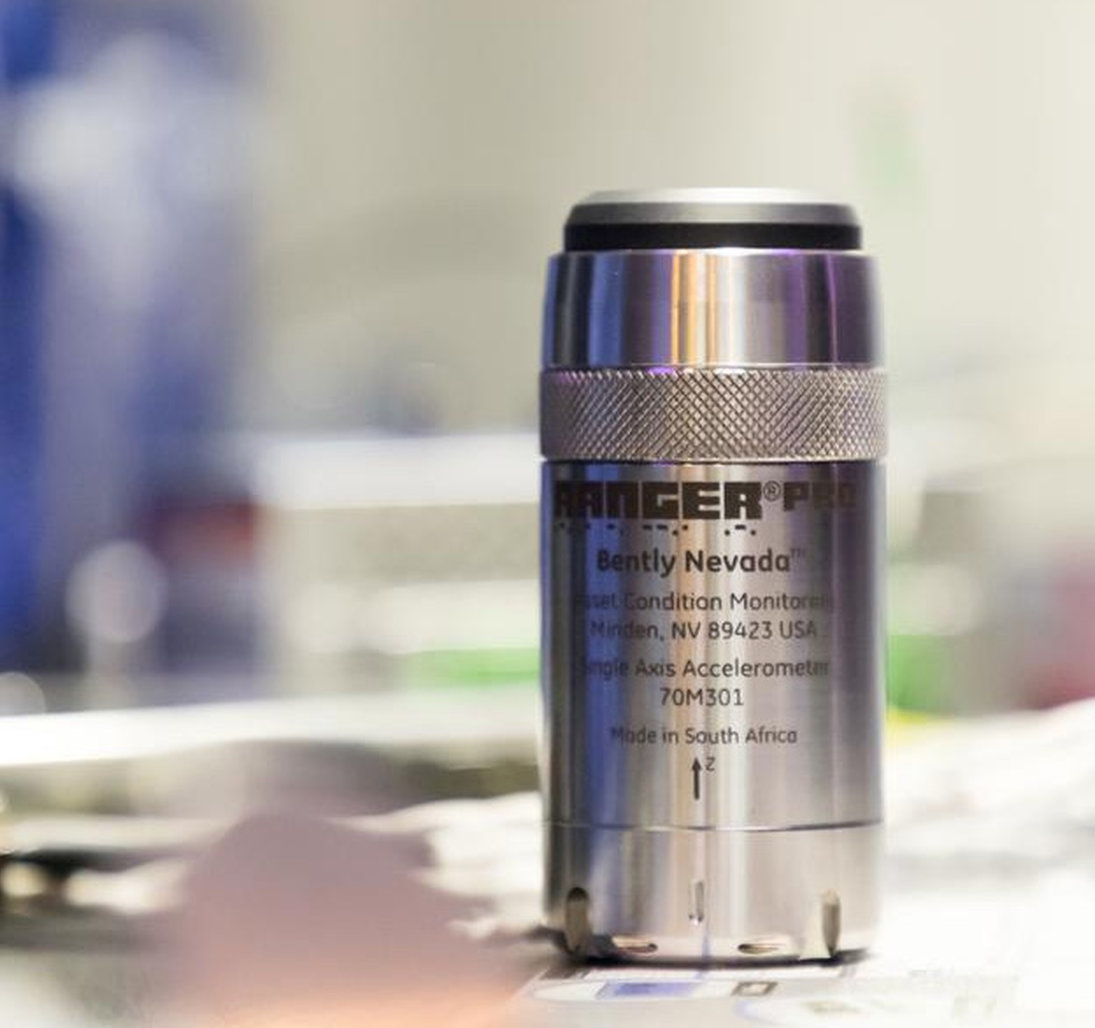

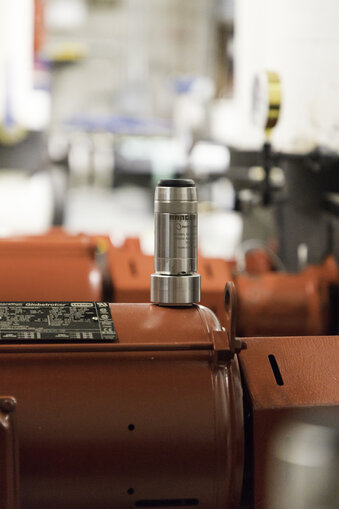

With over 10 million sensors installed worldwide and seven decades of experience, Cordant offers a comprehensive portfolio of sensors that are renowned for monitoring the health of customers’ equipment to help reduce maintenance costs and prevent unplanned downtime and machine failure.

Optimize maintenance costs and enhance asset health

Monitor assets accurately, reliability and continuously

Sensors that enable you to monitor the health of your assets accurately and efficiently, thereby improving process control and enhancing asset health.

Real-time data collection

Data collected real-time enables you to make timely decisions and drive immediate corrective action.

Adopt efficient maintenance processes

Leveraging sensor data enables a predictive approach to maintenance by identifying pending equipment defects for timely repairs before failure occurs.

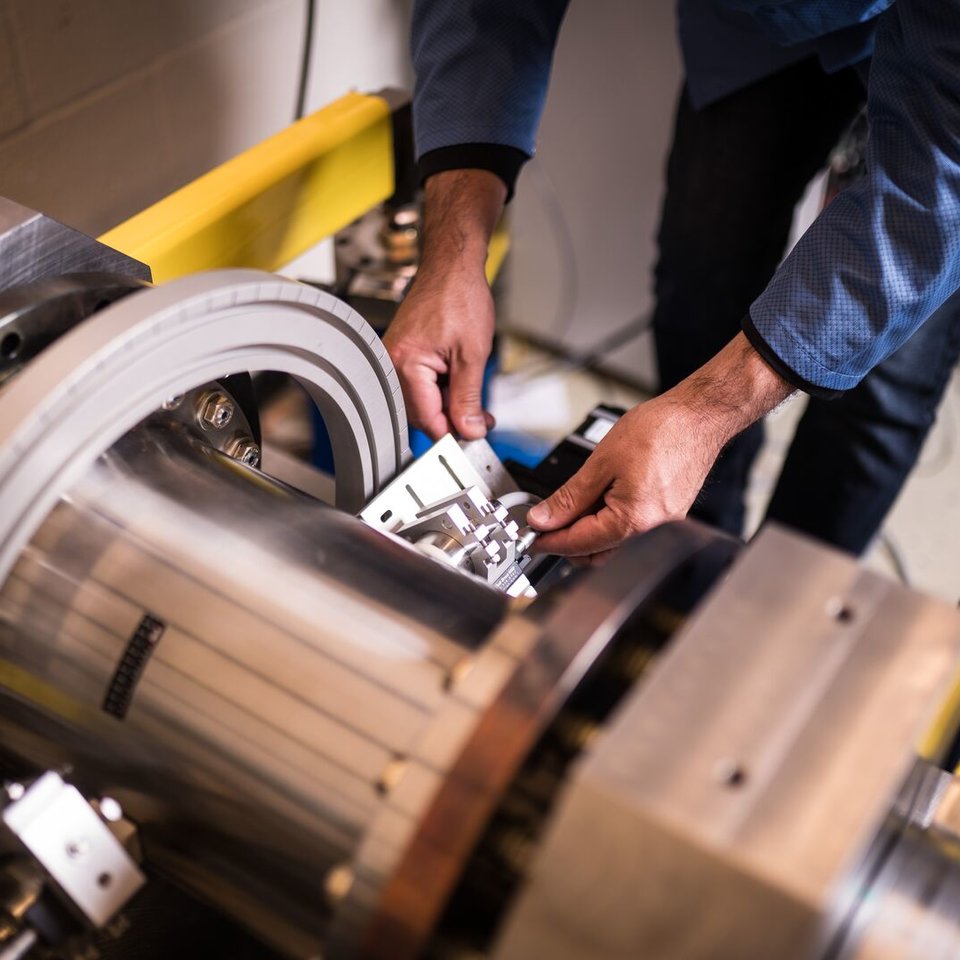

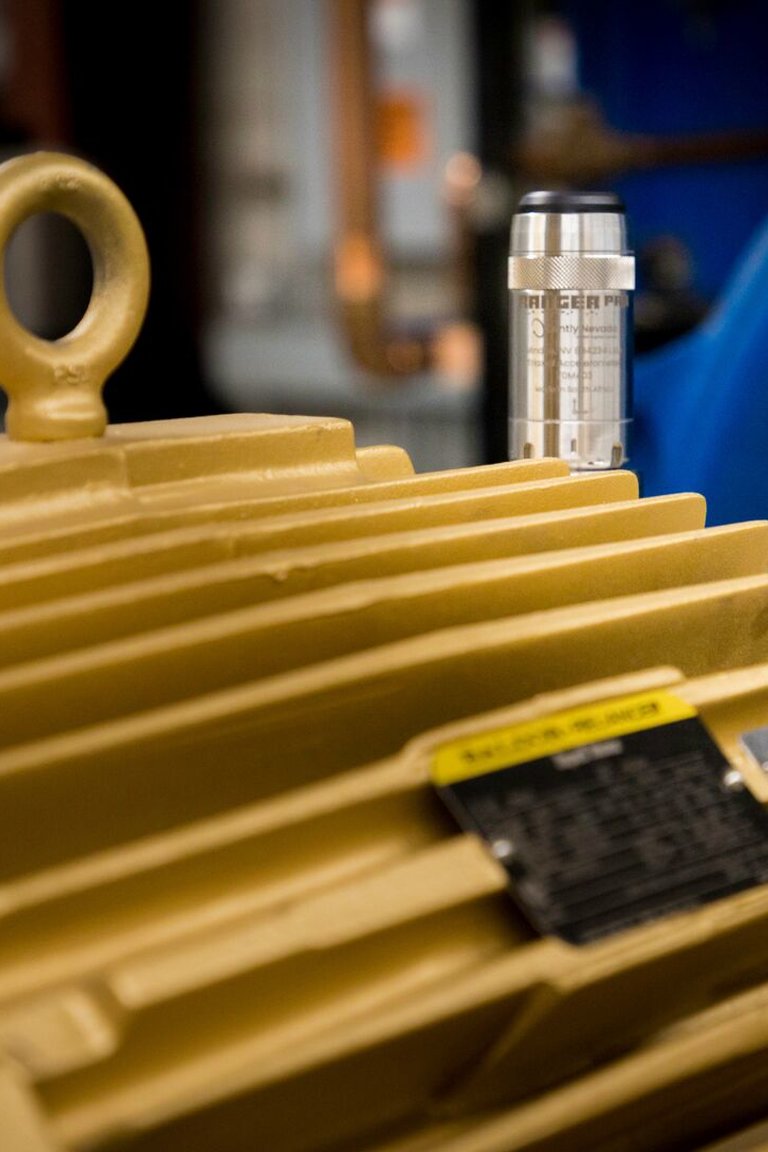

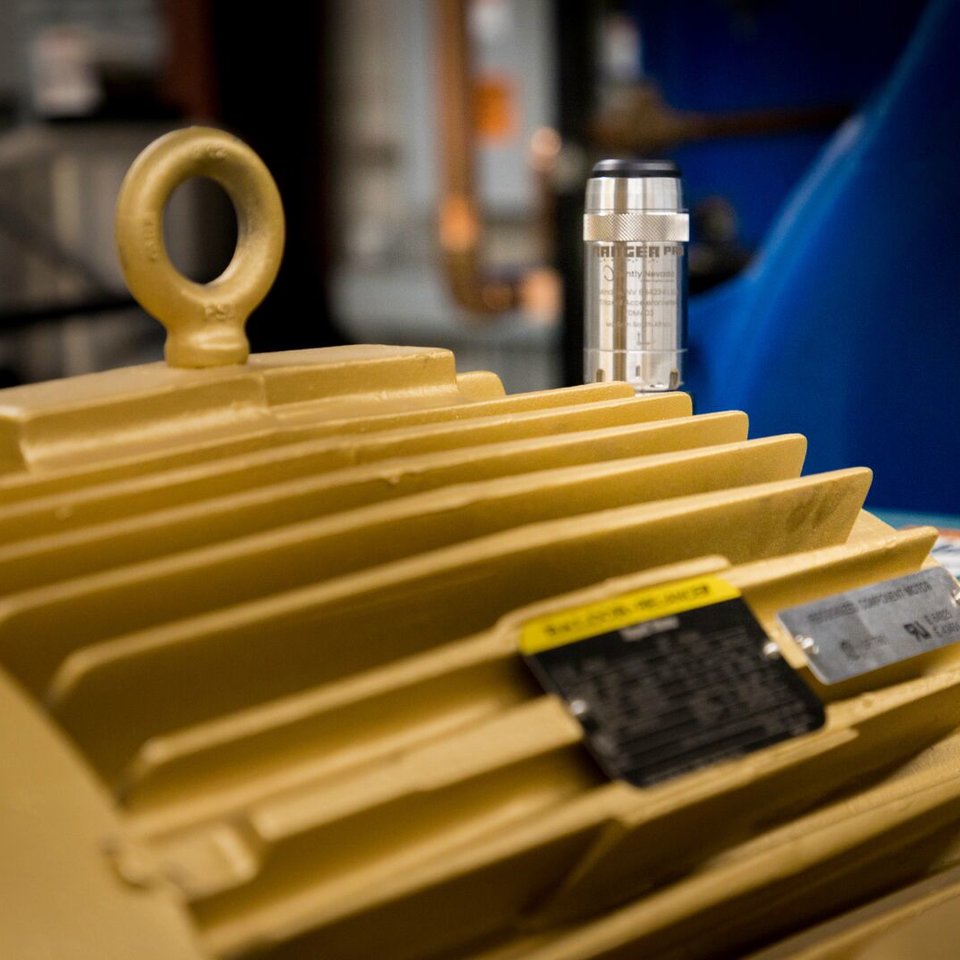

A comprehensive portfolio of sensors to monitor asset health

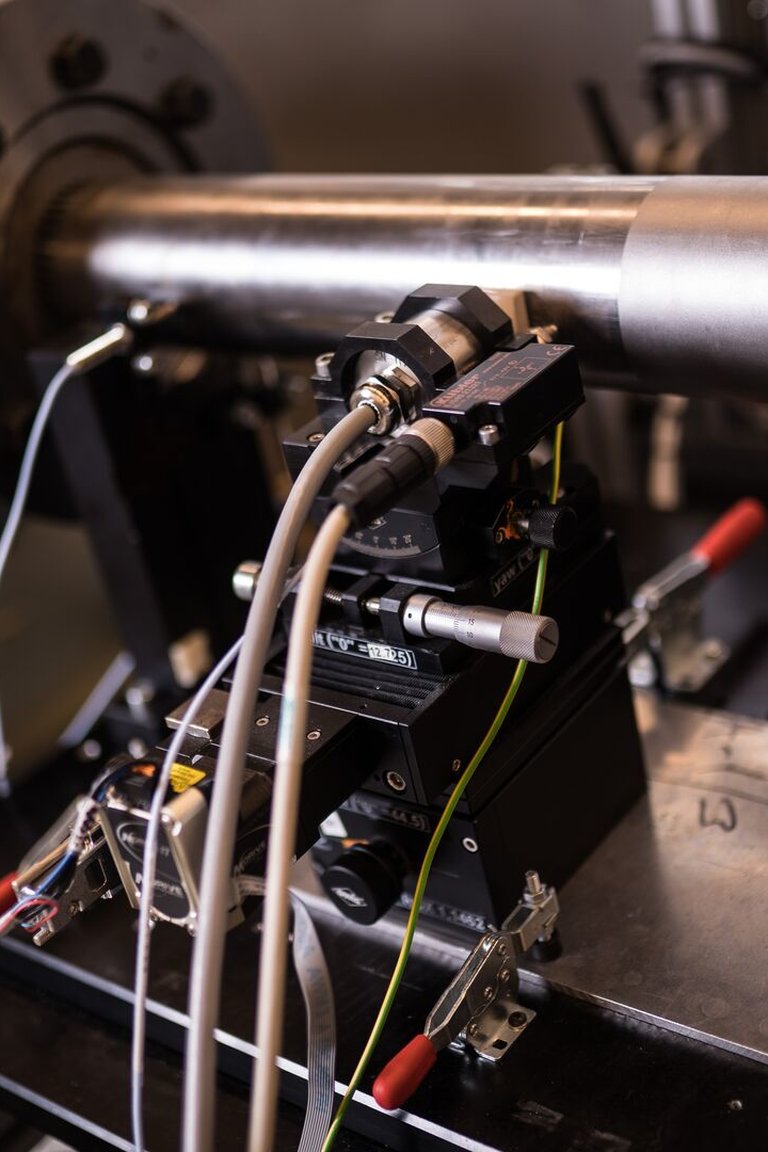

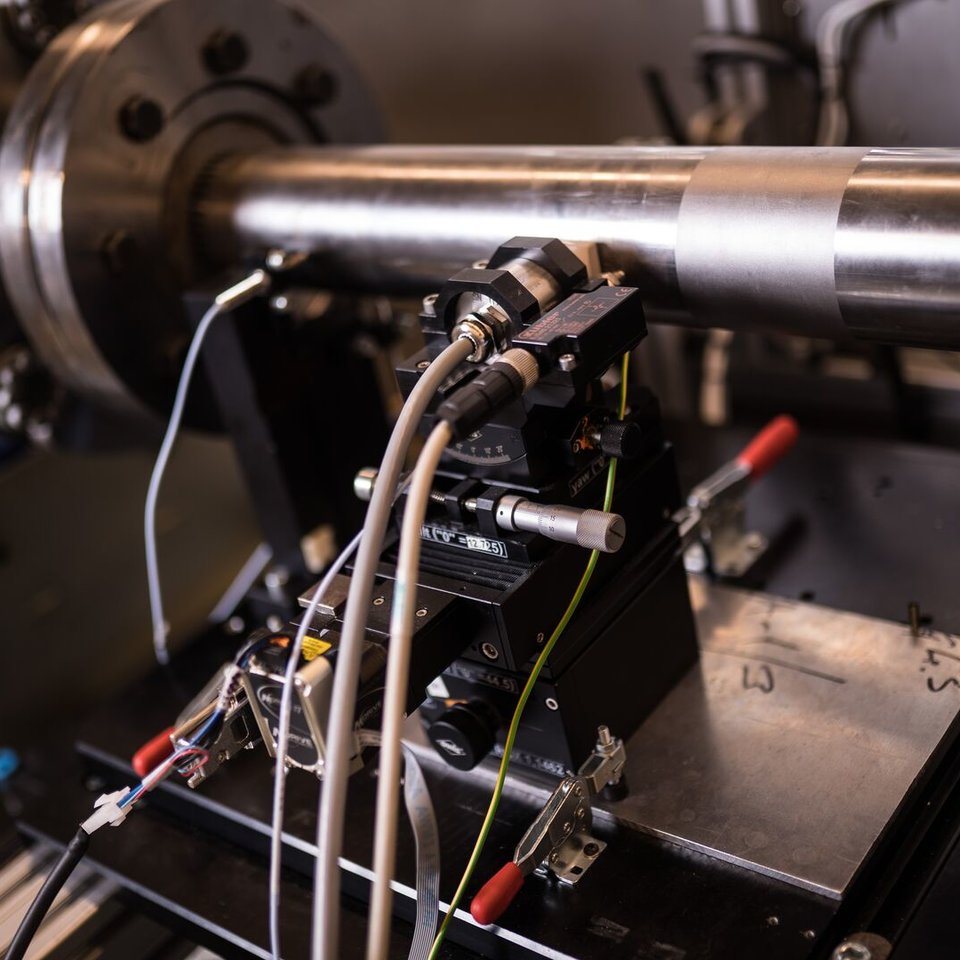

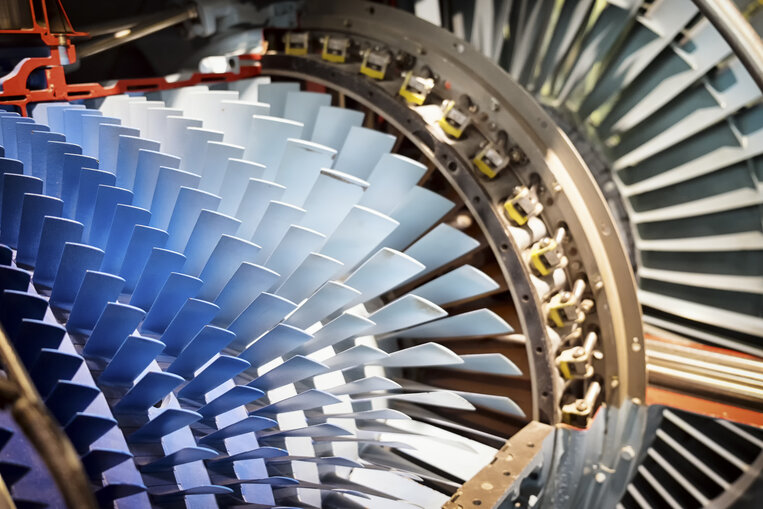

Measure rotor shaft position and vibration

Proximity sensors to measure rotor shaft position and vibration and deliver superior performance in harsh environments across a wide range of applications. The sensor technology family includes proximity probes, sensors and transducer systems to detect the presence of acceleration, velocity and pressure