Cutting the Cord (and the Cost) With Wireless Sensors

We live in a wireless world. Odds are good that you are reading this via a wireless connection. Sure, you may have fiber or cable supplying internet to your home or office (or home office as is the case these days) but your device of choice, be it a mobile phone, tablet, or even a full-fledged desktop, is likely tethered to the world at large via a wireless protocol.

This universal acceptance begs the obvious question: Why not consider wireless for industrial applications and gain the same productivity and convenience found in our home and office environments?

This is not a debate on wired vs wireless by any means. The reasons for wired yesterday vs today are just as valid, and in many instances, a wired connection is not only preferable but necessary. Wireless is simply advancing to levels that make additional industrial uses more applicable. The advances in bandwidth, security, power consumption, processing power, data storage, and environmental housings are some of the many reasons to explore where wireless can contribute to or even supersede previous applications where wired connections were simply not feasible.

So would you like to learn more about how wireless sensors can add both cost-effectiveness and reliability to your condition-based monitoring program? Great! Let’s start by introducing the industry leader in wireless condition monitoring sensors, the Ranger Pro.

Bently Nevada's Ranger Pro

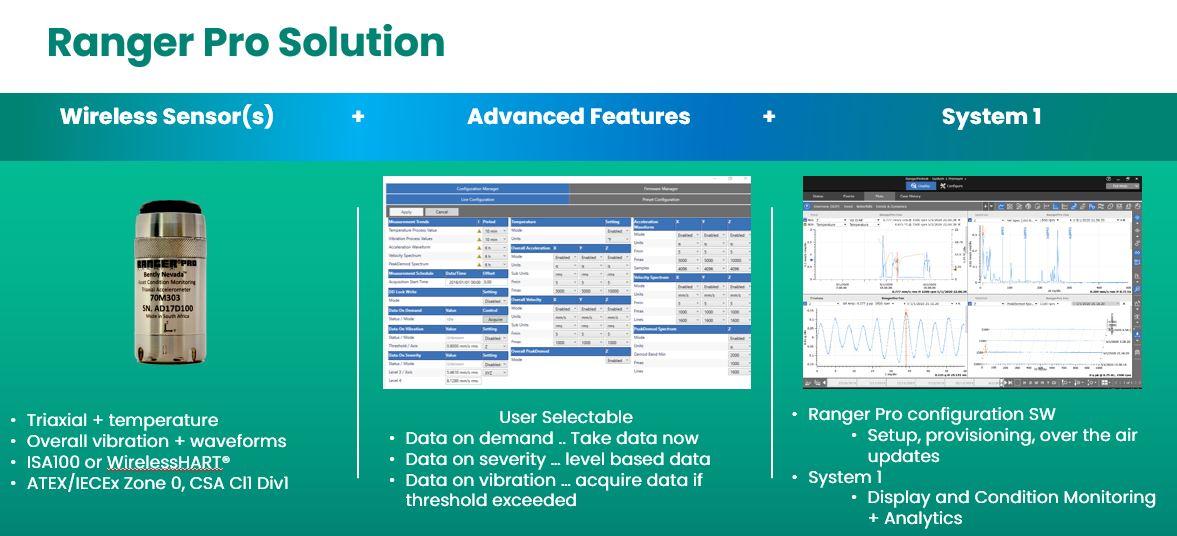

Bently Nevada offers a robust wireless solution for your condition monitoring needs in the form of the Ranger Pro, which can be adapted for use in multiple machinery applications.

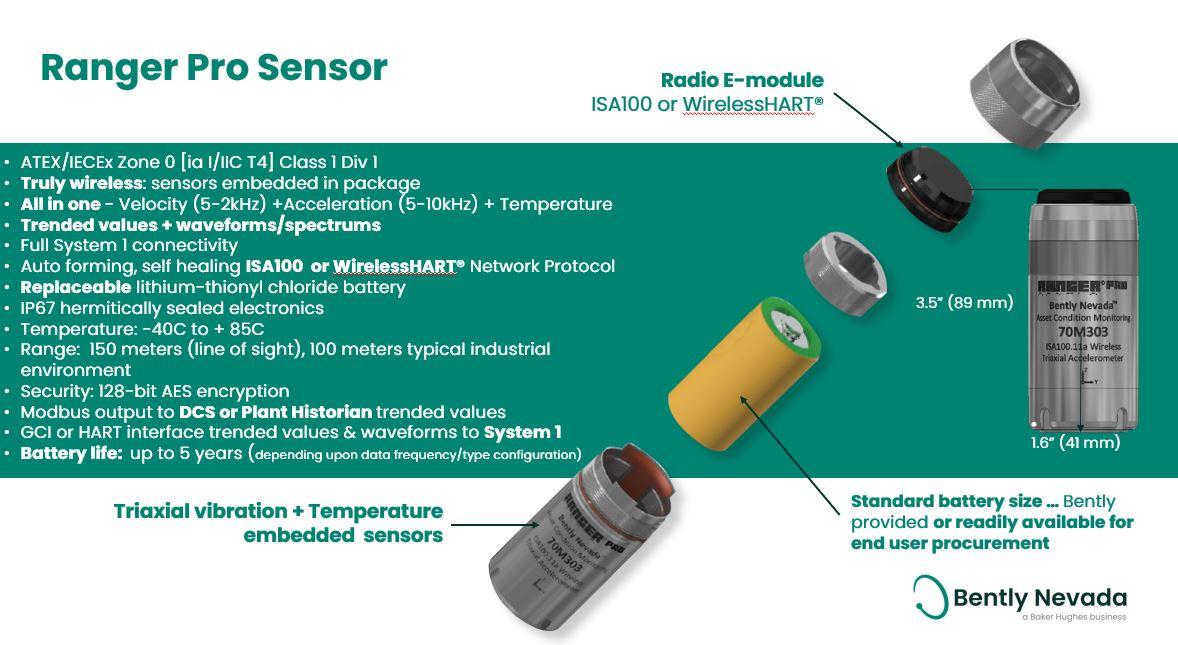

So what exactly is the Ranger Pro Wireless Sensor from Bently Nevada, aside from the obvious? The Ranger Pro Wireless condition monitoring sensor allows you to monitor velocity, acceleration, and temperature plus timebase waveforms, spectra, and PeakDemod spectrum. It's built for plant reliability managers and operators in power generation, oil and gas, and related industrial markets.

You can configure Ranger Pro Wireless Condition Monitoring to work in a variety of environments and applications:

- Uniaxial and tri-axial capable velocity and acceleration detection.

- Environment temperature reporting.

- Class 1 Div 1 (EX ia) hazardous certified

- Mounting hardware options to fit most applications.

- Standard replaceable lithium-thionyl chloride battery.

- IP67 dust and water-resistant.

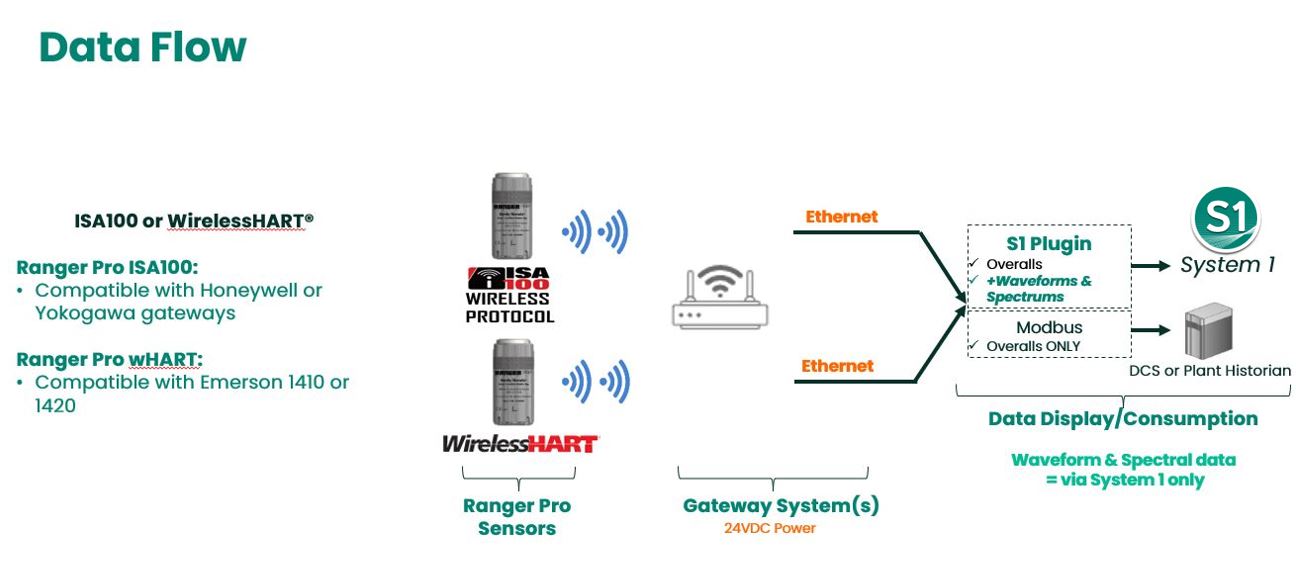

- ISA100 or WirelessHART protocol.

It is important to note that wireless range varies depending on environmental obstacles, gateway antenna type, and the orientation of the sensor relative to the gateway antenna.

Benefits of our wireless system

The Ranger Pro Wireless condition monitoring sensor is a simple, easy to implement solution for use in hazardous or difficult to access environments where wired or portable solutions become impractical. Thanks in part to the sensor’s inherent flexibility, the Bently Nevada Ranger Pro Wireless condition monitoring sensor enables you to do the following:

- Monitor and optimize the health and reliability of low- and medium- criticality machinery.

- Establish or expand existing reliability programs thanks to wireless monitoring.

- Make maintenance decisions based on current data, versus having to wait for in-person data collection.

- Reduce maintenance costs through deeper machine health insights, and data-backed decisions.

- Decrease unplanned machine failures by targeted maintenance that can be planned for minimal production interruption.

- Increase your organization’s machinery life.

You can use the Ranger Pro Wireless Condition Monitoring System to get immediate notifications, short- and long-term trending data, and diagnostic reporting. With Ranger Pro, you can transform your current portable data collections into portable data analytics by leveraging Ranger Pros as data collector sentries to identify those assets that warrant further analysis via portable or other means.

More reasons to go wireless with Ranger Pro

So aside from the flexibility of being deployed to various machinery types, what other benefits can you expect for your organization by adopting a wireless sensor strategy?

Data Collection Costs

By optimizing “reporting by walking around” via accurate, real-time data collection, your Ranger Pro Wireless system will save you labor costs, erroneous diagnoses, and unplanned production outages. The time savings are obvious, as you can get data instantly, but think too about the manpower savings, especially in larger organizations that have hundreds of machines, and where personnel qualified to interpret the data aren’t always the same people who are qualified to collect the data. This benefit is particularly valuable where dangerous or hazardous environments are present.

Installation Costs

Our compact, wireless design coupled with superior battery life makes the Ranger Pro the obvious choice for ease of installation, even in hazardous or hard to reach settings for the less critical assets. Think about those last two, hazardous and hard to reach settings. Running yard after yard of cable in a corrosive environment may require insanely expensive, specialized cabling that even in the best of circumstances will have to be inspected, maintained and replaced regularly. Then think about the customized sensor solution that has to be fabricated to adapt to a hard-to-reach piece of equipment, where cabling might require some additional engineering that could be nullified by the installation of a wireless sensor. Avoiding those material, labor, and design costs can more than pay for a wireless sensor in some applications.

Hazardous Area Installation

Our Ranger Pro wireless sensor complies with part 15 of the FCC Rules and similar EU RED, which mandates that operation must be subject to the following conditions:

- This device may not cause harmful interference.

- This device must accept any interference received, including interference that may cause undesired operation.

Additionally, the Ranger Pro is CSA certified for Class I, Division1 Groups A,B,C & D, ATEX/IECEx certified to Ex ia IIC T4 Ga and Ex ia I Ma standards. Finally, the Ranger Pro meets the 2011/65/EU directives for RoHS.

Seamless connectivity

Of course, all of this operational excellence is moot if your wireless sensor cannot connect with your condition monitoring software. Fortunately, the Ranger Pro has been engineered from the ground up to work seamlessly with System 1 and other third-party solutions.

System 1 support

After installing your Ranger Pro devices, you can set start times for multiple devices to begin data acquisition using Ranger Pro Configuration Software. Ranger Pro collects overall vibration, temperature measurements, timebase waveforms, spectra, and Peak Demod spectrum using Generic Client Interface (GCI) or HART-IP with System 1 condition monitoring software. You can filter overall and dynamic timebase and spectra data, giving you just the data you need, when you need it while still preserving all of the data for a detailed machine health history.

Network installation

Typical network installations employ several Ranger Pro Wireless Condition Monitoring sensors, Ranger Pro repeaters, wireless device managers/gateways, and access points. Ranger Pro is available in either uniaxial or tri-axial vibration detection set-ups. You can also quickly provision, configure, update, or change Ranger Pro devices over-the-air.

Security

The Ranger Pro leverages industry-proven protocols (ISA100 or WirelessHART) for 128-bit AES encrypted packets so you can rest assured your data and your network are protected and can be seen only by those who you want.

Connectivity

Is your organization tied to a specific wireless protocol? Are you in a WirelessHART or an ISA1001.11a environment? Well, with the Ranger Pro, you don’t have to choose as our sensor supports both protocols. 150 meters sensor to access point, 100 meters sensor to sensor, line of sight. (As with any wireless device, the actual range depends on obstacles present, gateway antenna type, and orientation of the sensor relative to the gateway antenna.)

Battery life

Obviously, a truly wireless solution requires that it run off a reliable battery supply. And a short battery life would defeat the purpose of trying to avoid the manpower sink of having to manually collect data at the machine, so your wireless sensor should have long battery life. The Ranger Pro, which employs an industry-standard replaceable battery that achieves a battery life of up to five years, depending on the operating mode and configuration settings.

Specification summary

So whether you are looking to break free of the costs associated with wired connections and their maintenance, or the manpower costs in having to collect data in-person, or you have hazardous or hard to reach applications that you want condition monitoring data on, a Ranger Pro wireless sensor from Bently Nevada can rise to the task and give you secure, real-time, accurate machinery health data while saving you resources.

We are in the ultimate downstream stoppage scenario right now, which affords forward-thinking organizations a unique opportunity to look at ways in which they can improve their current organizational processes overall and take advantage of ways to enhance their existing asset health programs in anticipation of future production events.

If you would like to learn more about Bently Nevada’s Wireless Ranger Pro sensor on your own, please visit the Ranger Pro Webpage:

Additionally, please feel free to contact your sales manager to schedule a time to discuss what a Ranger Pro wireless sensor plan can do for your condition monitoring program, or you can contact us here