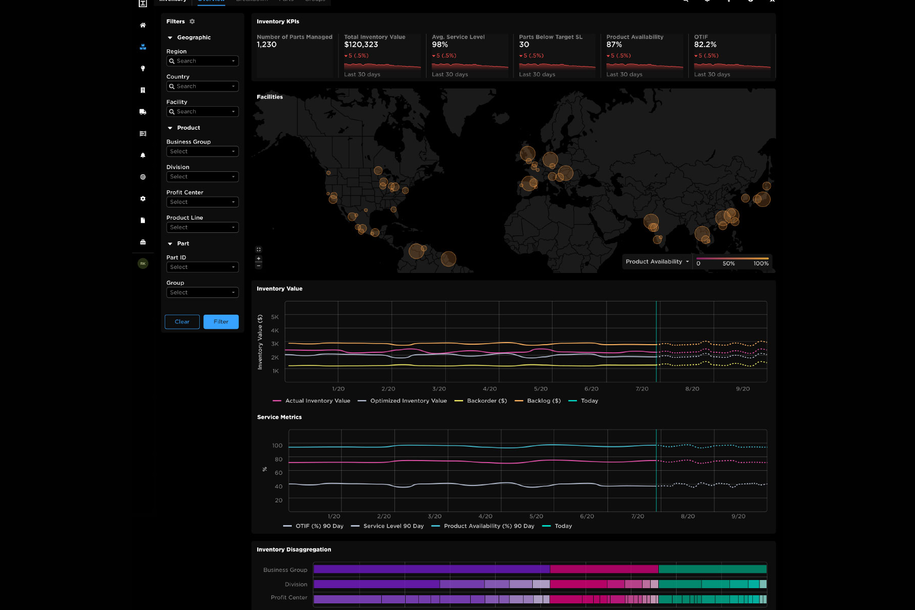

BHC3TM Inventory Optimization applies advanced AI, machine learning, and optimization techniques to help companies reduce inventory levels of parts, raw materials, and finished goods. While maintaining confidence that they will have sufficient safety stock to meet customer service level agreements.

Reduce inventory, improve service levels, and maximize OTIF

BHC3 Inventory Optimization Video

Demonstrated Benefits

Next Generation AI-based Supply Chain Operations

Pain Point

BHC3 Inventory Optimization Solution

Inability to view global supply chain in real-time

Full supply chain digital twin exposes all types of inventory in real-time

Excess raw material and parts inventory

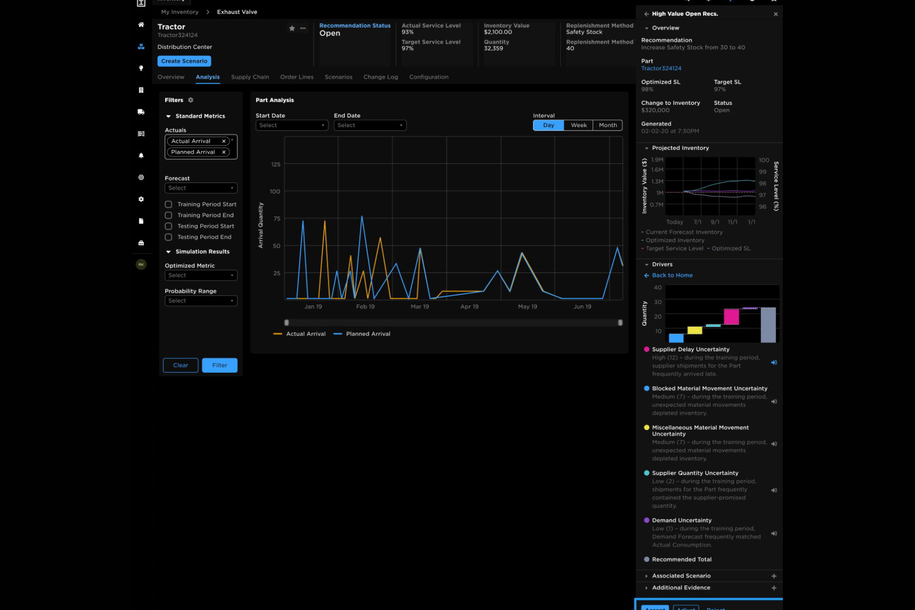

AI-based optimization recommends reorder parameter changes (e.g., safety stock)

Demand forecasts lack granularity

Part-level demand forecasts learn from actual historical variability in consumption

Cannot view part-level impacts nor explore Bill of Materials (BOM)

BOM exploration with part-specific service level details expose inefficiencies

Poor On-Time-In-Full (OTIF) delivery performance

AI-based lead time predictions and configurable alerts for projected late orders and supplier deliveries to meet OTIF targets

Disparate supply chain systems

Bidirectional integration with existing ERP and MRP systems support closed-loop action and feedback

Key Capabilities

Full supply chain digital twin

- Gain real-time visibility across all inventory.

- Create a single unified view of the supply chain integrating all ERP, MRP, and supplier data as well as external data.

- Trace parts through the supply chain to uncover insights and reorganize supply chains.

AI-based safety stock and reorder parameter recommendations

- Act on AI recommendations and view evidence package.

- Optimize inventory of parts at each facility level.

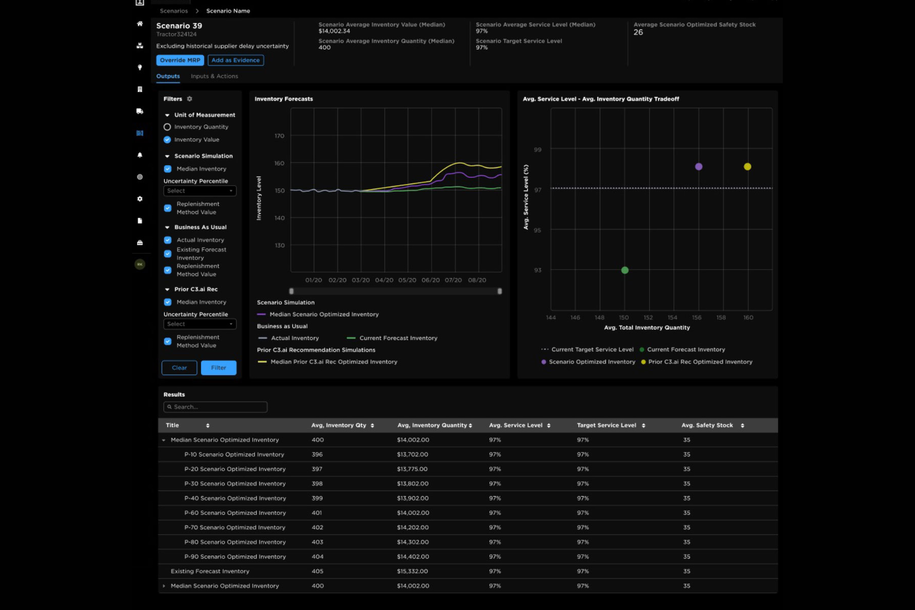

- Conduct scenario analysis before changing critical parameters.

Dynamic response to supply and demand variabilities

- Use actual data, not averages, to improve demand forecasting.

- Model each supplier with its unique variabilities.

- Use real-time weather and news data to highlight delay risks.

BOM exploration and detailed probabilistic scenario analysis

- Explore and analyze current and historical BOM configurations.

- Traverse BOM from finished goods to purchase parts.

- Conduct comprehensive "what-if" scenario analysis.

AI-based lead time predictions and configurable alerts

- Predict OTIF issues by identifying orders at-risk of delay.

- Receive recommendations to mitigate delay risk and increase OTIF.

- Configure facility-specific alerts and recommendations.

Direct integration into existing ERP and MRP systems

- Unify data from all global ERP instances

- Use bidirectional integration with existing systems of record

- Achieve improved S&OP performance

Benefits for Energy Professionals