Unlock hidden value: Add fixed equipment to plantwide condition monitoring ecosystem

Part 2

In part 1 of this article, I laid the foundation for why customers tend to spend more on fixed assets than rotating and reciprocating (R&R) assets and explained how they can more actively monitor fixed assets armed only with the data that is most often available from them: process data.

In part 1, I also provided two case histories from an innovative US-based refinery showcasing how they are using Cordant™ Asset Health, built on System 1™ to monitor these fixed assets—in addition to using it in its more “conventional” application to monitor their rotating and reciprocating machinery. Here are two additional examples of how this customer is using Cordant™ Asset Health and its analytics capabilities to monitor fixed assets and provide intelligent advisories.

Managing fixed assets with Cordant™ Asset Health: Two Additional Case Histories

#1: Rupture Disk Monitoring

Pressure relief valves (PRVs) protect piping, vessels, compressors, and other pressurized assets from excessive pressure conditions. While a PRV is intentionally designed to open under over-pressure conditions (i.e., 120% of design process pressure), the process conditions are often extremely corrosive. If the process gas were allowed to continuously contact the PRV, the valve would quickly corrode, resulting in leakage or seizure. Both conditions are unacceptable as leakage results in reportable incidents and associated penalties from regulatory agencies, while valve seizure could cause the pressurized asset to fail catastrophically.

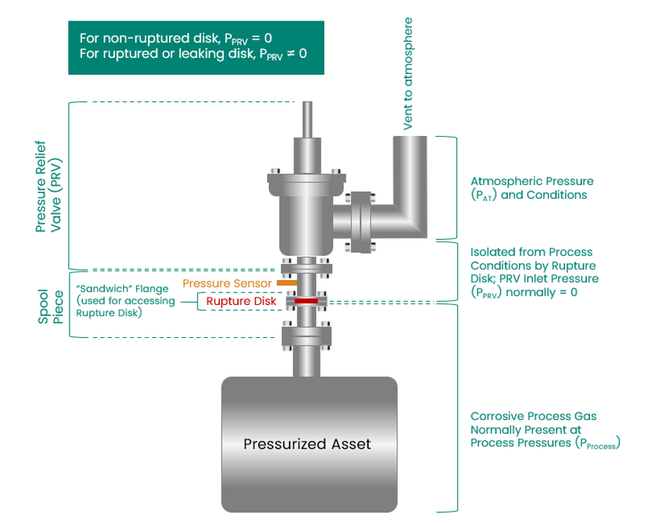

To isolate the PRV from the corrosive process gas, a rupture disk is used. The disk is a sacrificial, thin metal membrane designed to fail at a predetermined pressure. Further, it is designed using materials that are impervious to the corrosive process gases. As shown in the figure, the disk is placed in series with the PRV. This arrangement ensures the following:

- The PRV will not normally be exposed to the corrosive process fluid/conditions, thus preserving the PRV’s integrity

- Even a defective PRV (such as one that does not fully seal itself in its valve seat) will not leak to the atmosphere under normal process conditions

Under normal conditions, an intact rupture disk isolates the PRV from seeing process pressures; thus, PPRV ≈ 0. A fully ruptured disk results in PPRV = PProcess. A faulty disk, such as with a pinhole leak, results in PPRV ≠ 0. Thus, anytime PPRV is non-zero under normal process conditions, the disk is either ruptured or faulty (e.g., pinhole leak, etc.) and corrective action needs to be taken.

To help this customer manage their rupture disks and ensure regulatory compliance, a pressure sensor (or switch) is installed in the spool piece to measure PPRV. A simple rule in the Analytics engine detects when PPRV is non-zero and sends an e-mail notification to the engineers responsible for the affected area of the plant. They then inspect the disk and replace it with a new one if found ruptured or otherwise defective.

A failed rupture disk does not result in an atmospheric leak unless the PRV is itself leaky. However, the PRV will corrode unless the rupture disk is promptly replaced. Thus, even if it is not now leaking, the PRV will eventually leak as a result of contact with corrosive process gases. For this reason, regulatory agencies require a ruptured disk to be replaced within 15 days and appropriate records kept. As such, the Analytics rule also sends an e-mail notification to operation supervisors who are responsible for submitting an ICV (inter-lock control valve) bypass form. The ICV bypass form allows continued operation until the rupture disk is replaced. These records are audited by relevant regulatory agencies and the customer’s ability to show these agencies that a process is in place to constantly monitor the integrity of the rupture disk helps avoid violations and associated penalties.

#2: Stack Analyzer Monitoring

This refinery is required by law to monitor flue gas from their FCC (Fluid Catalytic Cracker) unit for CO, SO2, and NOX—all environmentally sensitive emissions regulated by law. The emission levels must be recorded and kept within allowable limits at all times. Monitoring is accomplished using a real-time gas analyzer that computes the concentrations of these emissions. However, to avoid violations and associated fines, it is necessary to periodically compare the gas analyzer’s results with laboratory results, verifying that the analyzer is not underreporting. Cordant™ Asset Health software is used to capture both the gas analyzer outputs and laboratory results and compare them to one another.

Discrepancies are flagged and appropriate personnel are notified using the Analytics engine.

Further, using Cordant™ Asset Health's ability to generate management-level alarms, violations are kept in check by notifying personnel whenever emissions approach maximum allowable limits. At 80% of the violation value, an alarm occurs, automatically notifying the unit supervisor and process engineer. This warns them of a possible environmental violation before it occurs, providing sufficient time to proactively intervene by adjusting the process.

If you’d like more information about Cordant™ Asset Health and its ability to help you manage fixed machinery assets contact us.