Modern, connected devices for action-oriented insights

In heavy industries, the way you maintain and manage your assets can have a significant impact on your operational goals. Whether it’s avoiding catastrophic failure and safety risks, or optimizing maintenance costs, every industrial facility has unique asset health needs.

Cordant™'s range of intelligent and connected devices ensures you have the right tools and data architecture in place to collect meaningful data about your assets. By leveraging advanced analytics and action-oriented insights, you can gain valuable insights and make informed decisions that enable you to meet operational goals.

Prevent asset failures and downtime

Monitor assets in real time and ensure early detection and resolution of impending equipment failure to minimize costly (and potentially catastrophic) impacts and downtime.

Optimize maintenance costs

Condition-based monitoring ensures maintenance activities are prioritized and proactively scheduled when it is needed – and not before. Saving you costs in maintenance and shutdowns.

Extend asset life, and save spares costs

Correct maintenance and preventive measures can safeguard equipment from unexpected shutdowns and ensure its longevity while also optimizing the cost of spare parts replacement.

We know asset health, we've got you covered.

+60 years and pioneers in condition monitoring

For more than 60 years, we’ve been supplying condition-monitoring solutions to machinery-intensive industries. We combine the highest quality products and responsive customer support with a service team that takes the time to understand the uniqueness of your plant, your personnel, and your goals.

Industries we serve:

Oil and Gas, Power, Chemical, Mining, Steel, Manufacturing, Wastewater

One vendor for all your needs

The maintenance industry is full of various monitoring solutions and technology partners. It can be daunting to select the best one for your facility, whether you're just starting or have all the necessary tools. However, our asset health solution is more than just a collection of products. We offer a true plant-wide unified hardware, software, and services asset health solution, which only a few companies can provide.

Our offering includes;

- Machinery protection and condition monitoring

- Sensing

- Software

- Services and training

Putting your performance at the core

News and Resources

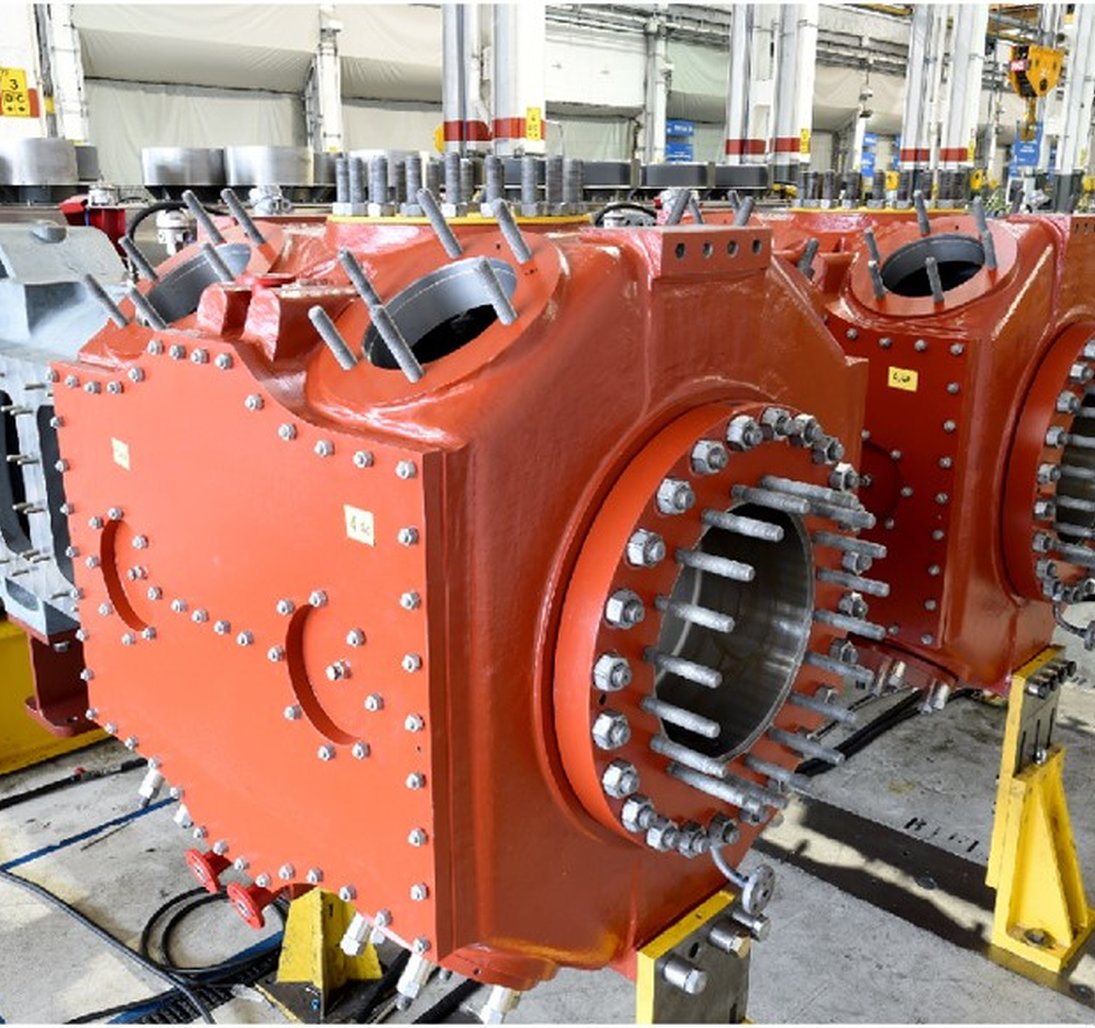

Reliability and maintenance teams collaborate to increase reliability

NATREF's reliability team established the framework on a recip compressor retrofit in coordination with Maintenance and Instrument teams by optimally utilizing spare slots in an existing 3500 rack and connecting to System 1 condition monitoring platform.