Reducing energy consumption at the edge

Cordant MachineEdge is an autonomous, AI-driven optimization solution for pump systems designed to improve energy efficiency and maximize reliability for customers in refining, petrochemical, chemical, and other process industries.

The innovative solution optimizes the combined performance of pump systems — pump, motor, and control valve. Using AI models and advanced analytics, Cordant MachineEdge predicts machine operating points and system conditions, and then autonomously sets the optimal motor speed without impacting the process control system. Cordant MachineEdge reduces energy consumption, resulting in lower energy costs and emissions, and improve machine reliability.

Supporting Your Energy Efficiency Goals While Extending Machine Life

Reduce Energy Consumption

Operate pump systems as one efficient, interdependent system, that automatically optimizes the combined machine performance to reduce energy usage.

Improve Machine Reliability

Manage equipment within the preferred OEM operating range to reduce excessive wear and tear caused by vibration, radial loads, and cavitation, to extend machine life.

Minimize Emissions Footprint

Run more efficient operations at the plant level with hundreds of pump systems optimized resulting in a significantly smaller carbon footprint.

Resulting in significant, collective savings

¹ Based on energy cost savings only. Does not include the value of CO2 emission reductions or maintenance and downtime cost reductions. Assumes electricity cost of $0.085 kWh USD (EIA US Industrial Avg.)

² Estimates based on retrofitting 250 pumps, with average energy consumption of 75 Hp (8760 operating hours, at 80% nominal speed); average energy savings of 40%, based on electricity cost of 0.0843 $/kWh (EIA US Industrial Average, 2022); emissions savings based on grid emission factor of 0.0003887 tCO2e/kWh (eGRID US Average, 2019)

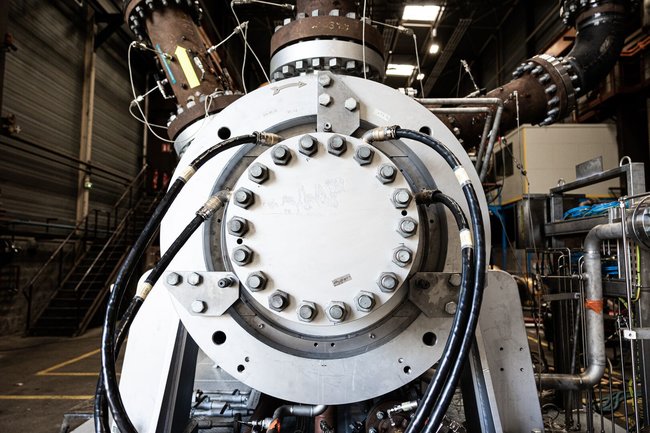

How Cordant MachineEdge optimizes existing pump systems

Combine and analyze key machine data points

This process starts when Sensor Input Data from the motor’s current and voltage sensors are combined and analyzed with its Knowledge Base information, such as motor, pump and control valve performance data, machine relationships, hydraulic principles and more.

Predict machine and process conditions

Leveraging this expanded data, Cordant MachineEdge will process Inference Data to predict machine and process conditions, and determine the best baseline motor speed that optimizes the future state of four interdependent variables: total energy consumption, motor operating point, pump operating point and control valve operating point.

Takes corrective action

Based on these predictions, Cordant MachineEdge determines the optimum motor speed and sends the appropriate frequency signal to the integrated power electronics that automatically controls the motor at the new baseline speed.