Oil and Gas | Subsea

Delivering sensing solutions in the demanding world of oil and gas solutions

Oil & Gas | Subsea

For over 50 years, Druck has been creating technology that has serviced the Oil and Gas and Subsea industries, partnered with more than a century of innovation and revolutionary technology from Baker Hughes, we harness the power of engineering, data, and science to redefine what's possible.

Drucks qualified pressure sensors and long-standing technological advancements have gained an industry wide reputation for excellence, gaining vast experience in design and qualification of custom-built pressure measurement solutions.

Druck is uniquely placed within the market to provide subsea sensor solutions encompassing a broad range of applications from drilling to Floating Production Storage and Offloading (FPSO) areas.

For example we are involved in:

- Wellhead pressure/temperature/flow

- Control pod pressure/temperature

- Downhole tool pressure/temperature/flow

- Subsea processing pressure/temperature/flow

- Pipe wall thickness

- FPSO flow/moisture/flare gas

- FPSO hydraulic power unit pressure

- Blow Off Preventers sensors (BOP)

- Subsea sensor simulators

The fusion of the innovative technology and packaging skills of the heritage Druck and Panametrics oil and gas companies, coupled with the financial stability, investment capability R&D and advanced manufacturing processes of Druck provides a powerful new partner to project manage your oil and gas measurement needs.

We will deliver low-risk solutions, innovative and high-performing products and the

finest customer support bringing the best results to you and your customers

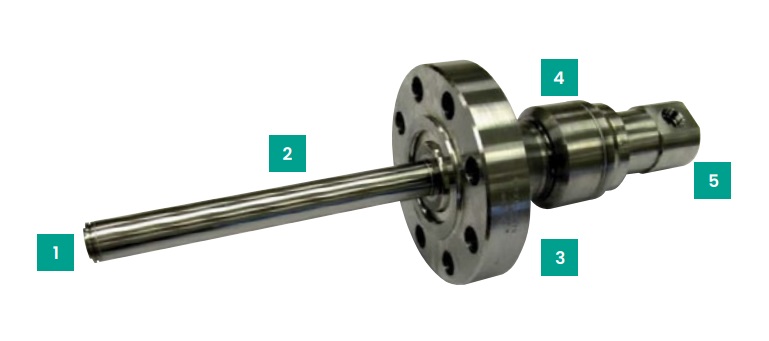

Pressure and temperature measurements across the tree are critical to controlling the well and to the asset management of the field. The expansion of the field-proven PTX 400 wellhead PT/TT sensor to a wide capability product with accuracies up to 0.025% FS and a full suite of analogue and digital interfaces provides customers with a full product solution within a controlled delivery period.

1. Module – Proven piezoresistive silicon technology for pressure and PT100 technology for temperature, single or dual configuration.

2. Nose tube – Customer length specified and electron beam welded to the flange and module.

3. Flange – Customer specified mechanical flange. Duplex stainless with an Inconel overlay on the process media areas.

4. Electronics housing – Single or dual PCB configurations located in the sea water area for ultra long life and high performance/stability.

5. Electrical seawater connection – Flexible configuration for any diver, ROV or jumper proprietary mechanical design requirement

Product capabilities

- Large 2500 installed product base

- Rapid tree delivery capability

- Ownership of the piezoresistive and resonating technology

- New state of the art manufacturing facility

- Single multifunction site of 650 people

Electrical interface

- 4 to 20 mA (all analogue)

- 20 to 4 mA (all analogue)

- 4 to 20 mA high performance

- 20 to 4 mA high performance

- PROFIbus high performance

- MODbus high performance

- CANbus high performance

The PTX 400 series sensor is a qualified set of sub components, which are brought together to produce a contract specific sensor solution.

The configuration of the unit is detailed in the following schematic and configuration table

- Module

- Nose

- Flange

- Electronic housing and mechanical interface

- Electrical connector

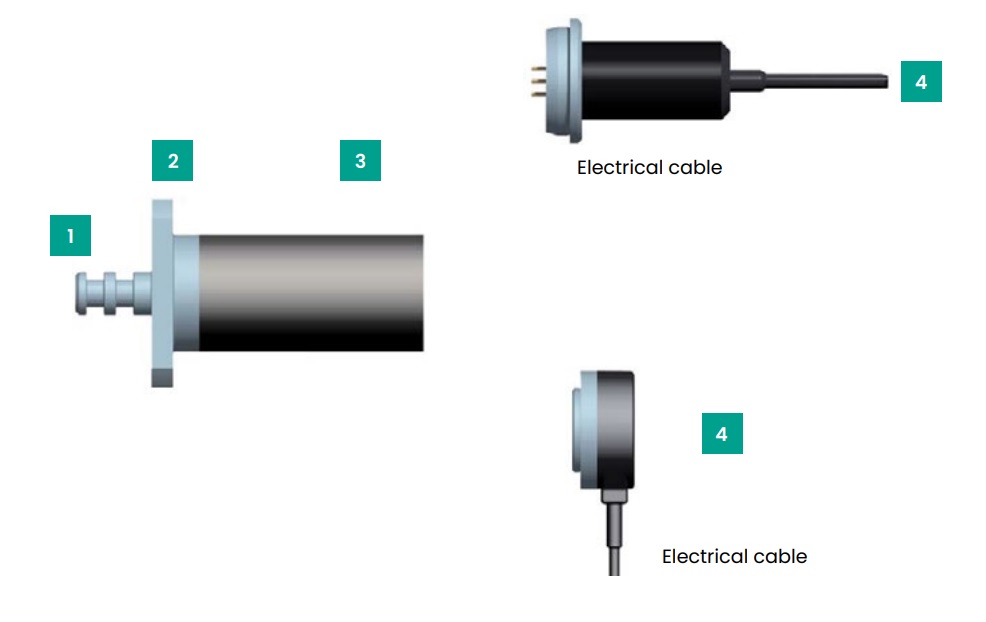

Measurement of hydraulic pressure within the subsea control module (SCM) at high hyperbaric pressures demands a reliable, compact and rugged pressure sensor to report on the health of the hydraulic control valves (DCV).

The PTX 300 series control pod sensor combines all these features within a ASME IX welded construction and consists, of qualified sub components, which combine to build a customized contract solution within a controlled delivery period.

1. Pressure connection – A broad range of subsea configurations from flange, screw thread for custom contract designs.

2. Pressure module – Field proven silicon technology housed in a 316 Stainless or all Inconel assembly designed for a fatigue life in excess of 25 years.

3. Electronics housing – High accuracy digital characterized electronics with 4-20mA or CANbus output with moisture protection.

4. Electrical connection – A broad range of field proven designs available with qualified hyperbaric pressure ratings.

5. Mechanical housing – Electron beam welded housing to ISO 13628 standards providing a hyperbaric protection up to 3000 meters.

Product capabilities

- Large 20000 installed product base

- Latest generation EB welder – weld integrity

- New lean manufacturing facility

- Comprehensive documentation packages

- Environmental sensor stress screening (optional) – Covers the most demanding contract specifications

Electrical interface

- 4 to 20mA (all analogue)

- 4 to 20 mA high performance

- CANbus high performance

The PTX 300 series sensor is a customized sensor to produce a contract specific sensor solution.

The construction of the unit is detailed in the following schematic and configuration table.

- Pressure connection

- Pressure module

- Electronic housing

- Electrical cable