Loose Part on Motor Cooling Fan

Industry: Offshore - Oil and Gas

Application: Dissolved Salts Pump

Solution: SSA - Remote Diagnostic Services - System 1† and Scout 220

On an offshore processing platform, machines of moderate criticality are monitored by periodic offline measurements using Scout 220. Mechanical technicians offshore take measurements and upload data to a System 1 server in Bergen using remote comms. The data is analyzed by Bently Nevada MDS Engineers.

While taking routine vibration measurements, a technician heard a “horrible noise” from a dissolved salts pump motor. Shortly afterwards he noticed the noise was gone and new measurements were taken. The measurements were then uploaded and support from MDS was requested.

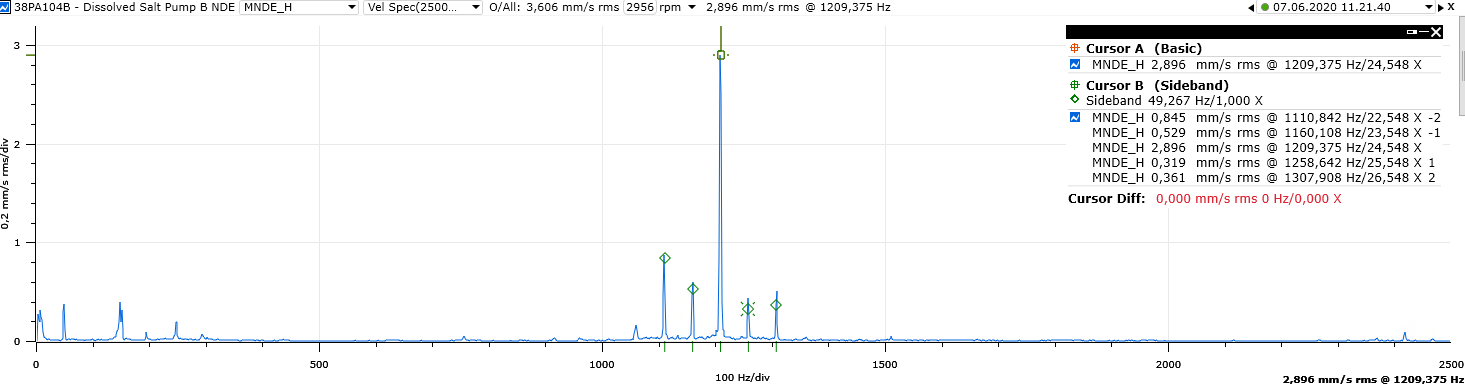

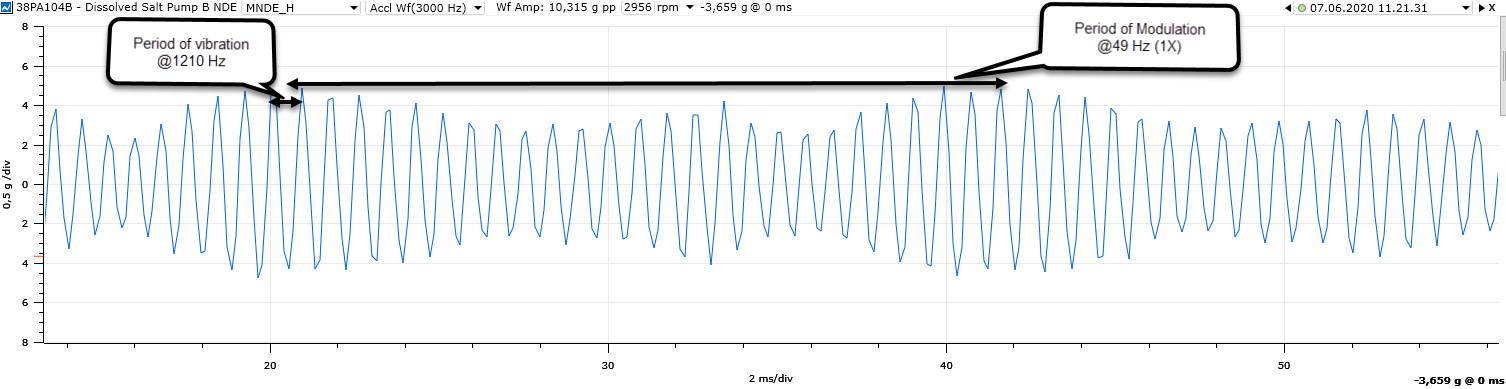

In the spectrum (Plot #1) there is a single peak at 1210Hz with 1X and 2X sidebands. Sidebands are produced by the FFT (Fast Fourier Transform) algorithm when a waveform (Plot #2) is modulated. The sidebands’ offset from the main peak are the modulation frequencies. This vibration was only visible on the motor non-drive end (NDE) measurement that were taken while the noise was heard. The peak did not match any expected forcing frequencies, and it was therefore thought to be an impact phenomenon exciting a resonance at 1210Hz with 1X & 2X periods between each impact.

The vibration frequency is close to the range (~2-5kHz) of sounds that human ears are most sensitive to. High vibrations at this frequency is therefore expected to be audible, which can explain the technicians experience of a “horrible noise”.

Based on the vibration pattern it was concluded that the impacting could either be caused by a loose part on the rotor or by contact between a rotating part and a stationary part, with the overhung cooling fan on the NDE as the suspected fault location. It was therefore recommended to open the fan cover and look for abnormalities on the cooling fan.

The fan cover was opened, and the smaller fraction of the part shown in Image #1 was found loose. The part is a retaining ring from the fan assembly which had come apart. Following this, the retaining ring was replaced by the technician, and the machine was back in operation less than 48 hours after the vibration measurements were taken.

If the fault had gone unnoticed, the fan could have separated from the rotor in operation and destroyed the motor. The cost of a new motor is approximately 40 000 EUR.

Author: Håkon Myklestad, Norway MDS

Copyright 2019 Baker Hughes Company. All rights reserved. 베이커휴즈는 이 정보를 일반적인 정보 목적으로 ‘있는 그대로’ 제공합니다. 베이커휴즈는 정보의 정확성 또는 완전성에 대해 어떠한 진술도 하지 않으며, 상업성 및 특정 목적 또는 사용에 대한 적합성을 포함하여 법률이 허용하는 한도 내에서 구체적, 묵시적 또는 구두로 어떠한 종류의 보증도 하지 않습니다. 이에 의하여 베이커휴즈는 청구가 계약, 불법 행위 또는 기타 방식으로 주장되는지 여부에 관계없이 직접적, 간접적, 결과적 또는 특별 손해, 이익 손실 청구 또는 정보 사용으로 인해 발생하는 제삼자 청구에 대해 일체의 책임을 지지 않습니다. 베이커휴즈는 통지 또는 의무 없이 언제든지 본 문서에 명시된 사양 및 기능을 변경하거나 설명된 제품의 제공을 중단할 수 있는 권리를 보유합니다. 최신 정보는 베이커휴즈 담당자에게 문의하십시오. 베이커휴즈 로고, 벤틀리 네바다 로고, System 1은 Baker Hughes Company의 상표입니다.