Druck ADTS returning fleet to operational readiness

The EASA (European Union Aviation Safety Agency) recently raised concerns around the challenges of returning aircraft to service following a prolonged period of storage.

As the world tentatively looks to emerge from the pandemic and thinks about travelling again, whether it be for leisure or business, a large number of aircraft need to be serviced and returned to operation.

One of the EASA’s concerns was around debris and wildlife being found in aircraft systems. There have been reports of aircraft having to return to base during a flight due to incorrect airspeed, altitude and angle of attack measurements caused by debris in the pitot-static system.

Another concern that was raised was around re-training and refamiliarization of the workforce as they return to work. Errors with equipment calibration and testing can be disastrous when it comes to key flight systems resulting in aborted flights or worse.

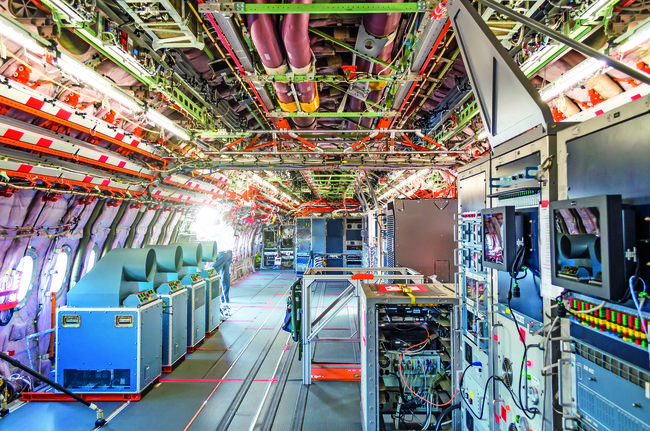

By utilizing one of the range of simple and easy to use Air Data Test Sets (ADTS) from Druck you can be confident that your technicians can, quickly and efficiently, confirm that pitot-static systems are working correctly and delivering correct airspeed, altitude and angle of attack measurements before putting them back into operation.

Talk to an ADTS specialist near you | Schedule an online demo

The performance of our sensors and their unrivalled levels of accuracy and reliability provide you with the peace of mind that the pitot-static system on your aircraft is functioning as it should when aircraft return to service. In addition, the automated operation and simple user interface support technicians in returning to work and re-familiarizing themselves with the testing process.

Druck’s 500 series ADTS are equipped with TERPS (Trench etched Resonant Pressure Sensor) technology delivering unprecedented levels of accuracy and performance in the field. This results in real world accuracies of better than 12 ft at 41,000 ft, 7ft at 29,000 ft and 2 ft at sea level, well within the 80ft Reduced Vertical Separation Minimum (RVSM) allowance for an aircraft. Our customers tell us this performance is market leading and results in peace of mind for the technicians and airlines alike.

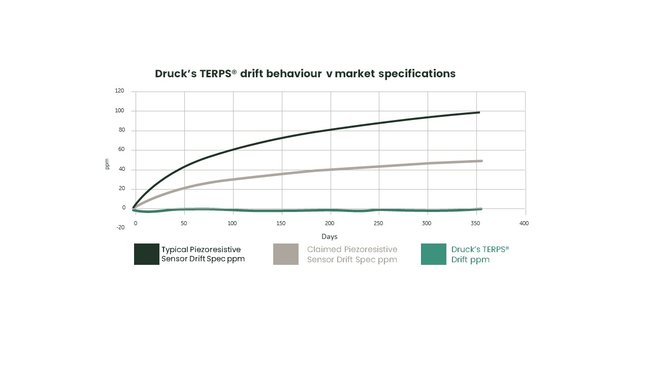

At Druck we always include the precision, the calibration expanded uncertainty and the drift into the accuracy values we provide. This ensures we know exactly what the uncertainty impact is on the RVSM allowance of the aircraft. Not all pitot-static test set manufacturers follow this best practice of providing all sources of measurement uncertainty however, so before purchasing any pitot-static tester, the buyer should investigate whether the accuracy value stated includes drift for the recalibration period, temperature effects, calibration standard uncertainty and control stability.

In the graph below we show the typical drift for our TERPS technology and compare its drift performance over time against the drift performance claimed and achieved by other instrument manufacturers. Whilst Druck’s specification includes a 20 ppm FS drift per annum and 30 ppm drift over 18 months, Druck has observed that the drift performance of Druck’s TERPS® over time outperforms this specification significantly. It is this stability that allows us to offer standard 15 month calibration periods on all our 55X series (with an option to extend to 18 months), and 12 months on our 542 series (with an option to extend to 15 months). This extended calibration period reduces the cost of ownership through less calibrations being required (4 calibrations in 5 years for a 55X series) but also less ADTS’s being needed in the fleet to cover while units are away being calibrated.

In short, if you are looking for peace of mind that your aircraft is being tested with the most accurate and stable test sets on the market with an easy to use and intuitive interface then you need one of our Druck ADTS 500 series.

To find out more please click here to connect with a Druck representative.

Druck is one of the world’s leaders across aviation pressure measurement and has supplied more than 500,000 sensors to the aerospace sector providing unrivalled levels of accuracy and reliability across applications including: hydraulics; environmental control systems; fuel, auxiliary power unit; engine measurement; air data measurement; & cabin pressures.

View one of our related new articles.