Condition Monitoring Using Portable Data Collectors and System 1

Introduction to Portable Data Collectors

Portable data collectors, or simply Portables, are typically small data collection systems that can be taken from machine to machine to collect asset health data. Portable devices normally have between one and four vibration input channels, and in some cases also capture temperature, speed, and other process data. Their use often takes the form of portable ‘routes’, which consist of machines and measurement locations. Portable data collectors capture waveforms and spectrums that can be analyzed offline or compared against past measurements, enabling a window into evolving asset health conditions.

For lower cost-of-failure assets, taking snapshots periodically can bridge the gap between more expensive online monitoring solutions and the complete absence of asset monitoring, which can increase the risk of production disruptions. However, the offline nature of Portable data collectors requires that a person move the system from asset to asset, which can be time-consuming and generally results in measurements being made infrequently, such as once a month. As with any approach, a balance must be considered. What is clear is that every machine, no matter how low cost, can benefit from a data-driven reliability strategy.

Use Cases for Portable Data Collectors

Rolling Element Bearing Machines: For machines employing rolling element bearings, which often wear-out relatively slowly, a Portable data collector can be an effective means of tracking the degradation of wearable components and help reliability professionals maximize component life, while avoiding unplanned downtime of the asset. For machines subjected to more abrupt failure modes, an online monitoring approach is typically favored, as it increases the likelihood of advanced notification of impending machine issues or failures.

New Condition Monitoring Programs: Portables offer a cost-effective way to stand-up a new condition monitoring program. Oftentimes, organizations use portables as an initial step in their transition from preventative or reactive maintenance strategies to more-effective predictive or reliability-centered maintenance strategies. The success of portables programs often leads to the introduction of online and wireless monitoring for assets requiring more frequent data collection or for assets not easily accessible for measurements with a portable device.

Balancing and Alignment: Another use of portables is for machine balancing or alignment. A portable device can provide the insights into balance or alignment necessary to make adjustments to the machine train to correct imbalance and misalignment issues.

Supplemental Dynamic Data Collection: Portable data collectors are often used to provide more insights into vibration issues for assets that do not have online monitoring systems capable of capturing waveforms and spectrums, or those systems that are limited in how often they can capture these measurement types (e.g., wireless sensors or 4-20mA vibration transmitters). These ‘basic surveillance’ solutions can indicate a problem, but oftentimes do not contain the intelligence or capabilities to capture the dynamic data required to pin-point the problem or confirm it has been properly addressed. Portables can provide the missing view into asset health and enable reliability professionals and maintenance teams to take the necessary corrective actions.

Selecting a Portable Data Collector

As the selection of a portable monitoring device can be complex, it is helpful to consider the following criteria:

- Number of measurements required on each asset

- Number of axes required for each measurement location (e.g., single versus tri-axial)

- Types of measurements (e.g., vibration, tachometer, or keyphasor†)

- Common analytics extractions or measurements required to understand the health of the asset (e.g., spectrums, waveforms, overall vibration, peak or demodulated peak vibration, etc.)

Bently Nevada’s SCOUT100, SCOUT200, and vbSeries portable data collectors come with a variety of features to meet the needs of reliability professionals, including models designed for use in hazardous areas. A few of the key features are listed below:

- On-route & Off-route for all supported measurement types: waveforms, spectra, orbits acceleration, velocity, displacement and demodulation, process or keypad entry

- Analysis at the Machine: Bump test, time-synchronous averaging, order tracking, synchronized sampling, and interval capture during machine run-up or coast-down

- Rugged, lightweight designs: All Portables go through a series of tests designed to ensure their suitability for Industrial use, including drop tests (1.2m), waterproof tests (IP65+), and battery life tests (10+ hours on a single charge). Furthermore, our portables are designed to be light-weight (<1.2kg).

- Fast data collection: An automatic settling algorithm, optimized sequencing, and 6Pack Recordings† ensure quick data acquisition after detection that the sensor has stabilized

- Multi-channel: Our portable hardware monitoring devices support multi-channel vibration data collection, analysis, and balancing. Between 1 and 4 channels of data may be captured simultaneously along with a tachometer or keyphasor input enabling speed and/or phase synchronous measurements

- Advanced analytics: A complete suite of advanced recording and analysis capabilities, including 6Pack recordings, machine coast-down measurements, and long-time waveform capture, enable more advanced analytics techniques

- Hazardous Area Certified: SCOUT models are available with ATEX Class I, Zone 2 hazardous area ratings, while the vbSeries models are available with CSA (C US) Class I, Division 2 ratings, providing common certifications for various uses worldwide. Intrinsically Safe (IS) models are available for CSA and ATEX Class I, Division 1/Zone 1 hazardous area environments.

- Safety: Safety is enhanced through the use of a neck strap with an integrated sensor keeper to ensure safe containment of the device and sensor while walking or climbing.

- Bluetooth connectivity: Our data collectors use Bluetooth to efficiently connect and communicate with industrial handheld smartphone or tablet devices, which are available for use in hazardous environments

Condition Monitoring Software

A key differentiator of Bently Nevada’s broad product offerings is the ability to bring data from portable devices into our System 1† condition monitoring software - the same analytics and visualization environment used by other protection and online condition monitoring systems typically found on more critical assets in the plant. System 1 condition monitoring software supports data from a broad range of vibration instruments and wireless sensors. Its data historian is capable of handling data from online, scanning, wireless sensors, portables and process-derived data – enabling reliability professionals to understand the health of their assets with clarity and context.

Key Features of System 1

System 1 offers quick configuration capabilities, which enable offline definition of assets, instrumentation, and portable data collection routes. This helps reliability professionals save time when defining routes and measurements. Configuration time is further reduced through the use of templates, which allow data collection and measurements defined for one asset to be applied to other similar assets.

System 1 also offers configurable band alarms. These analytic extractions or measurements make it easy to trend features in a vibration spectrum that tie closely to specific failure modes of an asset. The ability to define band alarms that indicate imbalance, cavitation, alignment and a wide range of bearing or gearing faults enables more prescriptive diagnostics of machine issues, especially when trended over time. An additional benefit of System 1’s software-defined alarms are its ability to back-calculate extractions from all stored historical dynamic data.

To assist with issue identification, System 1 includes a statistical alarm setpoint tool, which looks at previously collected trend data to recommend alarm setpoints. This tool is useful when adding a new asset to a monitoring route, especially when the engineer does not know what baseline levels of vibration to expect. Initial setpoints can be chosen and then refined using the statistical alarm tool once sufficient baseline data has been stored. The statistical alarm setpoint tool analyzes recently stored data to determine proper setpoints, simplifying the selection of appropriate alarm thresholds.

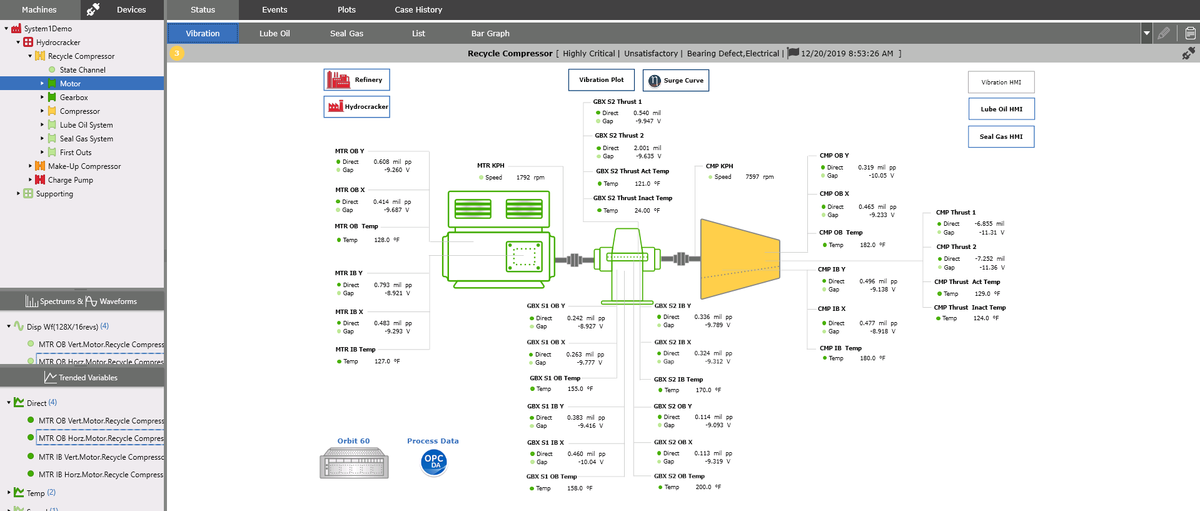

A unique capability of System 1 is its diagnostic HMI, which allows reliability professionals to view asset health graphically. Diagnostic HMIs consist of machine diagrams that incorporate measurements and colors to provide context of an asset as part of a larger machine train or process unit. When monitoring many like-assets, these views can be defined once and quickly applied to other assets. An example of HMI view is shown below.

Once an alert has been generated, System 1’s advanced plotting capabilities enable easier fault identification and root-cause analysis. Fault frequency overlays, default plot sets, waterfall plots, and advanced cursor options and scaling provide the tools necessary to quickly identify degradation in component or asset health.

System 1 has integrated report generation capabilities, enabling efficient report generation after an issue has been identified. In addition, Fault Conditions, Notes, and Plot Records are stored directly within the System 1 database, allowing users to more easily collaborate and preserve their combined knowledge over time.

Finally, System 1 offers the capability of storing baselines for future comparison as well as machine audit reports, which allow the archiving of data associated with a particular failure mode for reference at a later time. These audit reports can form the basis of failure mode libraries, which can be leveraged across an entire organization to more easily understand similar issues in the future.

Summary

Portable data collectors and System 1 software from Bently Nevada play a critical role in the monitoring of assets with a lower consequence of failure. They can be used to gather dynamic data on machines without online systems, to troubleshoot machine issues, and offer a cost-effective solution for Plant-Wide predictive maintenance programs.

Partnering with Bently Nevada allows you to begin your condition monitoring journey today, while knowing you have a trusted partner to support future expansion to more assets and expanded monitoring solutions.

To learn more about Bently Nevada’s line of portable data collectors and System 1 condition monitoring software, visit our Portables and System 1 webpages or Contact Us.