Bearing Wear Due To Improper Installation

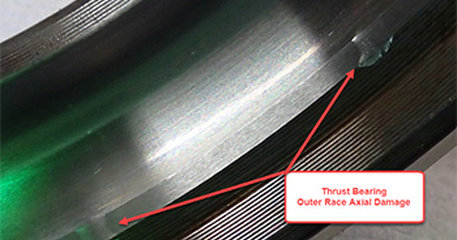

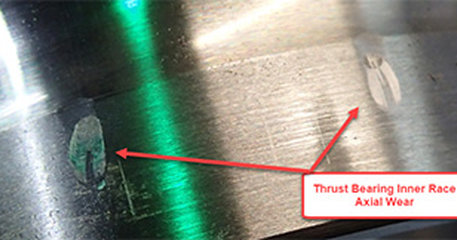

Damage was found on one of the thrust bearings, where the roller elements showed axial movement beyond the tolerances. This was because the bearing was found sitting away from its designed mounting position on the shaft (possibly due to installation error). Cage damage was also found during the overhaul.

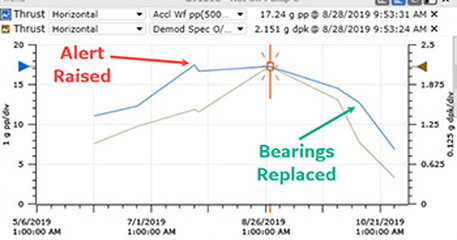

Pump bearings are open oil fed bearings, so continuous growth in dissipated energy from the bearings was indicative of bearing wear.

The acceleration levels were first monitored, over a 3-month period, but there were no signs of improvement. Based on the analysis, the decision was made to intervene and replace the pump bearings.

The client noticed elevated overall acceleration levels on the pump side bearings in July 2019. During following vibration surveys in September of the same year, the client observed continuous, gradual growth in acceleration levels.

The issue was resolved by replacing the pump bearing, and during the overhaul significant damage to the bearing was observed.

Timely intervention due to efficient machinery diagnostics for unit C using Scout 140 - System1 prevented the loss of production as unit B was also diagnosed with potential issues.

As a result, there was an estimated savings in breakdown maintenance costs of £50k. The estimated prevent of production lost cost per day is greater than £100k.

Copyright 2019 Baker Hughes Company. All rights reserved. Baker Hughes provides this information on an “as is” basis for general information purposes. Baker Hughes does not make any representation as to the accuracy or completeness of the information and makes no warranties of any kind, specific, implied or oral, to the fullest extent permissible by law, including those of merchantability and fitness for a particular purpose or use. Baker Hughes hereby disclaims any and all liability for any direct, indirect, consequential or special damages, claims for lost profits, or third party claims arising from the use of the information, whether a claim is asserted in contract, tort, or otherwise. Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product described at any time without notice or obligation. Contact your Baker Hughes representative for the most current information. The Baker Hughes logo, the Bently Nevada logo, and System 1 are trademarks of Baker Hughes Company.