Vibration Signatures Roller Element Bearings: Before & After an Overhaul

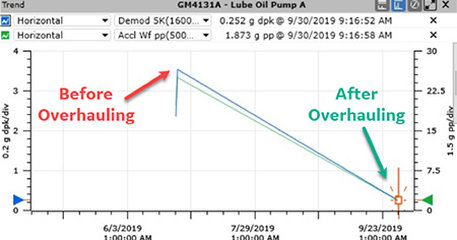

One of our customers was made aware of the elevated acceleration levels on the Motor in January 2019. Spectral content showed harmonics of running speed frequency with noticeable impacts in the waveform. Afterwards, the G4131A was taken out of operation but was run again in June 2019 without any intrusive work done on it.

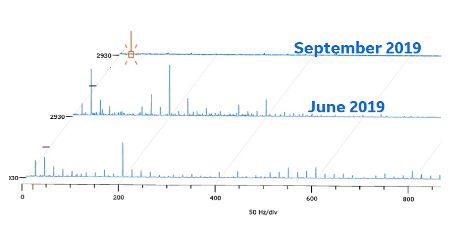

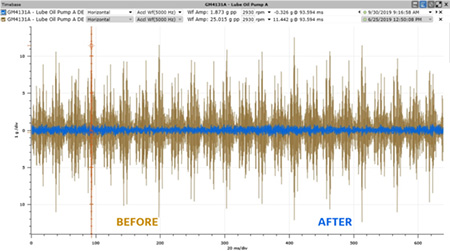

The elevated bearing stress was initially recorded and highlighted in January however further step increase was recorded in June. (Please note that unit was not operation from January 2019 till June 2019.) In June 2019, sharp impacts were recorded in the Time Waveform during the vibration survey conducted.

The demodulated spectra showed harmonics of synchronous frequency which is potentially indicative of mechanical looseness or excessive bearing wear on the Motor. The customer was advised to stop the machine and overhaul the Motor which was finally accomplished in September 2019.

Running speed harmonics in spectral content and sharp impacts in the Time Domain is normally indicative of mechanical looseness / excessive bearing wear.

The unit was finally overhauled in September 2019 and acceleration levels came down to satisfactory levels.

- Through their Supporting Services Agreement, utilising portable data collection from a Scout 140-IS and System 1, this UK refinery was able to avoid unscheduled downtime and retain machine train availability for operation.

- Estimated breakdown maintenance cost saved is £20k.

If you would like to learn more about Bently Nevada’s Roller Element Bearing- Condition Monitoring Solutions:

Copyright 2019 Baker Hughes Company. All rights reserved. Baker Hughes provides this information on an “as is” basis for general information purposes. Baker Hughes does not make any representation as to the accuracy or completeness of the information and makes no warranties of any kind, specific, implied or oral, to the fullest extent permissible by law, including those of merchantability and fitness for a particular purpose or use. Baker Hughes hereby disclaims any and all liability for any direct, indirect, consequential or special damages, claims for lost profits, or third party claims arising from the use of the information, whether a claim is asserted in contract, tort, or otherwise. Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product described at any time without notice or obligation. Contact your Baker Hughes representative for the most current information. The Baker Hughes logo, the Bently Nevada logo, and System 1 are trademarks of Baker Hughes Company.