China Coal Chemical Facility Avoids Extra Downtime

Customer Type: Coal Chemical

Industry: Oil and Gas

Application: CO Compression

Solution: Retrofitted the damaged bearing lube oil seal and cleared the spacer.

Following an outage Bently Nevada Machinery Diagnostic Services (MDS) team identified a gradually increasing unbalance with a carbon monoxide (CO) compressor at a coal chemical facility in China. The problem was quickly resolved which avoided unplanned downtime and severe impacts on mass production schedule - estimated savings of $4M USD.

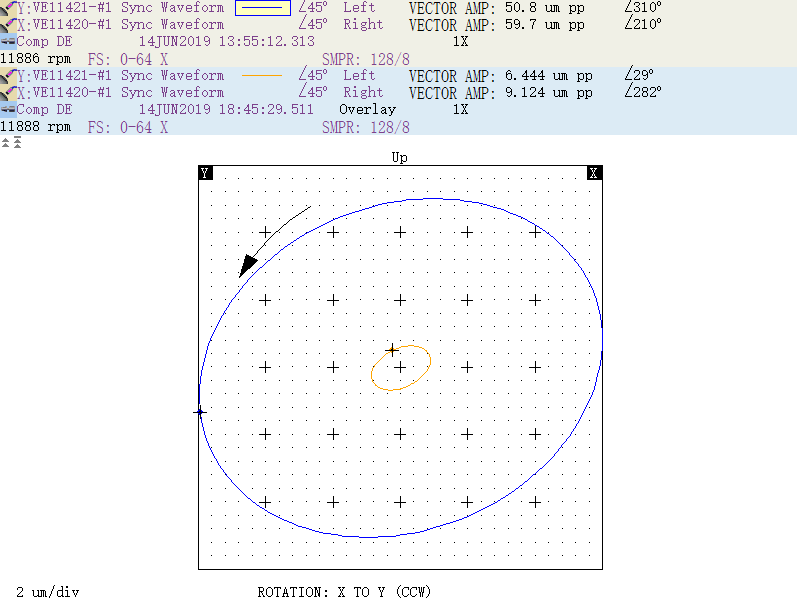

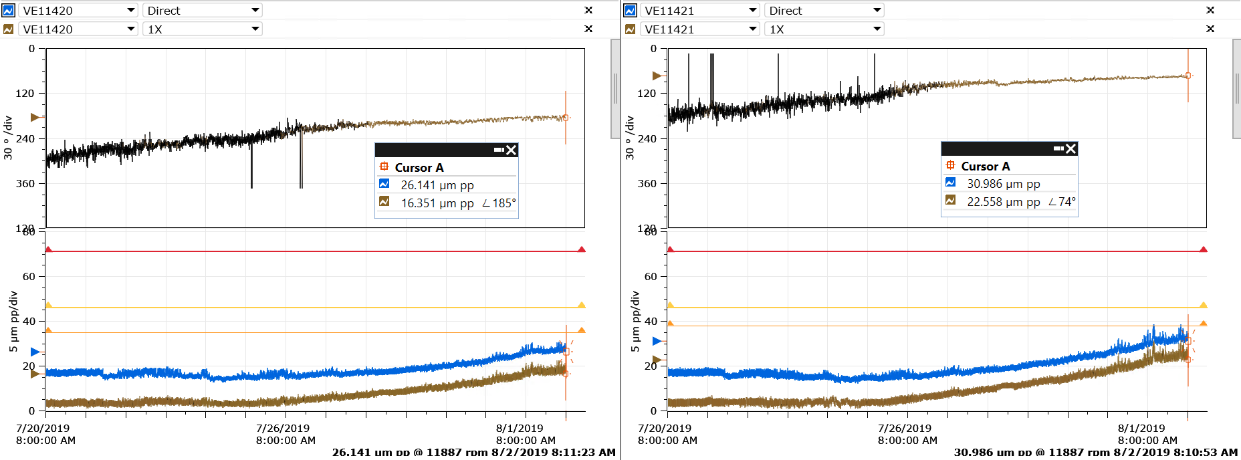

Bently Nevada Services team was invited to support the post-outage startup of a coal chemical facility in China, which was currently being monitored by the latest generation of System 1†software. During the initial review of the data within System 1, it was determined that the compressor needed to be balanced. Although the balancing program was successful at first (see Fig. 1), the compressor started presenting gradual increase in vibrations during subsequent runs (see Fig.2).

This CO compressor it is one of the main critical machines since it produces basic CO raw materials of acetic acid. In case of a trip of this machine, the company would lose at least 470K USD per day (7 days would be needed to resume). Given the machine's criticality to support the plant’s operation, it was of extreme importance to quickly correct the existing issue. As the reason of gradually increased vibration was due to 1X frequency, it was then suspected a change over the time of the unbalance. For this reason, an inspection of the machine was requested.

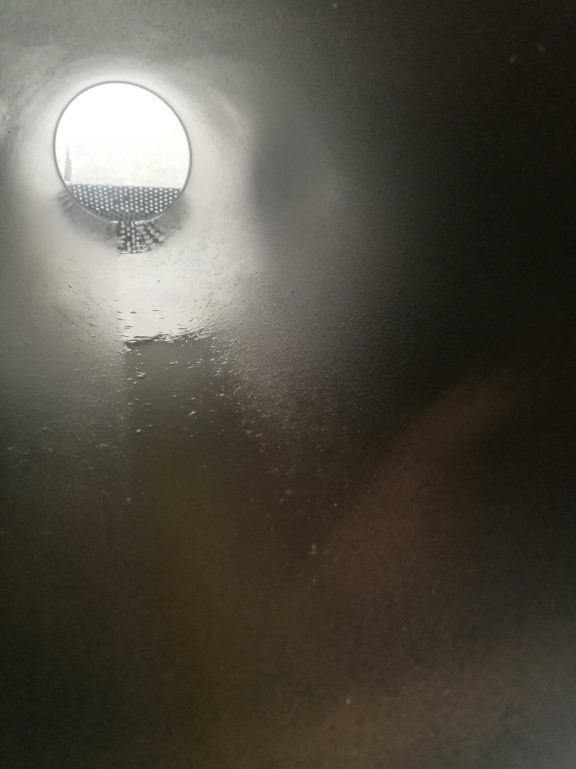

During the following downtime inspection, the Bently Nevada team noticed an accumulation of lube oil within the coupling spacer (see Fig.3), which could be a sign that the lube oil was leaking to the spacer (oil seal is located closer to the spacer), creating an unbalance. The bearing lube oil seals were then retrofitted per discussion with OEM and customer (see Fig.4). As a result, the undermining oil was cleared out from the hollow spacer.

The problem was quickly solved, and the customer resumed its regular operations.

Machinery Diagnostic Services team’s assertive and fast diagnostics convinced the customer of Bently Nevada’s technology value. Support Service Agreement (SSA) online monitoring and analysis was key to identify the root cause of the machine malfunction, ensuring quick and effective problem-solving actions and avoiding extra downtime and cost. Considering the 470K USD of production loss per day and the maintenance cost, total savings can be estimated to 4M USD.

Authors: Dongzhen XU and Jianping NIE

Our Experts

Dongzhen XU

Site Services Specialist

Jianping NIE

Services Specialist