Remote monitoring and diagnostics services

Bently Nevada remote monitoring systems and diagnostics

The workforce is shrinking. Experienced onsite technical resources need to be replaced or developed at the required rate. Employees are tasked with additional duties that reduce the time they can devote to managing and reviewing condition-monitoring data. Industrial organizations don’t have the people, remote management, or experience to get the most out of their condition-monitoring devices or automation investment.

It’s time to partner with those who know remote monitoring solutions best.

The diagnostics expertise of Bently Nevada will give you maximum insights from your machinery data so that it can be more effective. Our diagnostic experts help to maintain safe machine operation with minimal downtime by recognizing problems before they happen.

We monitor and analyze machine vibration, temperature, pressure, critical process parameters, server health, data communication, and instrumentation integrity. We use secure, remote access to find abnormal behaviors and characteristics to make actionable recommendations.

Bently Nevada is the rotating equipment industry’s premier partner and service provider. Our team of more than 150 machinery diagnostic engineers can support your operations through any of our six global centers.

Our thoughtfully tailored offerings ensure you realize maximum benefits, with three package options, as well as remote monitoring-as-a-service that complements our hosted System 1 solution, Bently Connect. We are committed to improving the health of your assets, allowing you to realize the maximum value of your investment.

Service Details

- Software alarm/notification tuning: review, change, implement, configure applicable software states and software alarms.

- Software reference data optimization: enhancement of system functionality based on historical machinery behavior and establishing reference data for future comparisons; ensures the correct data is captured at the correct times and displayed in the correct formats.

- Baseline health audit report: includes a full review of available vibration and process data for all ranges of operating conditions, with a report on any machinery, system, or instrument anomalies.

- System health checks: reviewing and assessing server health, System 1 health, and vibration protection/monitoring system health.

- Server health includes operating system hard drive usage, System 1 database hard drive usage, CPU usage, reviews of both application event log and system health log

- System 1 health includes data acquisition status, System 1 version status, database backup status, and data store span, consumption, size, age, and health

- Vibration protection/monitoring system health includes hardware configuration status, software version status, firmware version status, and instrument health

- Periodic machinery health report:: summary of the review, investigation, and documentation of A&E occurrences on a periodic basis. This is available for hosted, connected and non-connected System 1 customers. The report is supplemented by a conference call to discuss findings and update the statuses of the cases.

- Onsite visits: periodic site visits by a certified field engineer to review and assess the health of the Bently Nevada hardware, software, and workflow.

- Alarm and event management: implementing and managing software alarms within their condition-monitoring software to proactively manage machinery assets. Evaluating alarm conditions to detect and diagnose instrumentation and machinery problems before they become serious.

Reduce unplanned or extended compressor outages with Bently Nevada's remote monitoring for reciprocating compressors

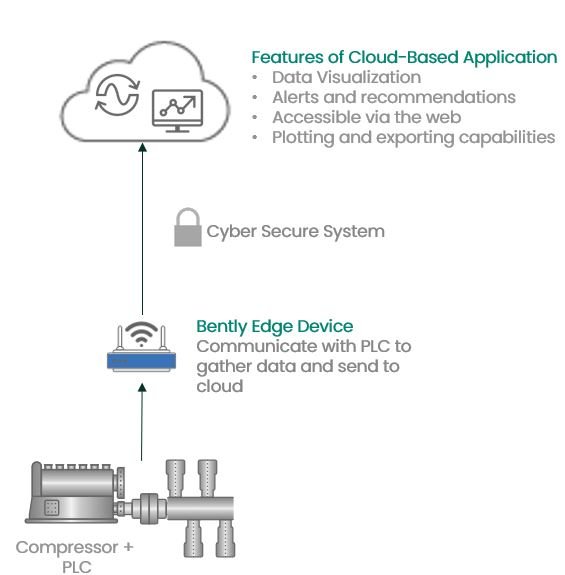

Bently Nevada can provide remote monitoring, advanced predictive diagnostics, and performance analysis for reciprocating compressors, with applications ranging from gas injection to booster stations, aiming to maximize unrealized benefits.

The Bently Nevada service includes:

- Automated analytics—user-friendly performance and diagnostics

- Subject matter expert data review

- Regular summary reports, coordination, and follow-up calls to resolve issues

- Intuitive HMI for data visualization and detailed analysis