Heat Exchanger Efficiency Monitoring

Summary

Heat exchangers are used widely in all industrial segments across many different processes. Maintaining high efficiency performance across the lifetime of a heat exchanger is a significant challenge due to many factors, including cooling liquid flow issues such as build ups, corrosions, leakage, etc. Preventing these issues impacting on performance requires continuous monitoring of the energy efficiency. It is common to check the pressure before and after the heat exchanger to make an assessment. However, the data is often inaccurate and unreliable.

Operation teams can use more reliable and accurate solutions to monitor their heat exchanger’s energy efficiency and reduce energy losses.

Application

Customers can measure the flow rate through the heat exchanger together with the supply and return temperatures to calculate the energy being transferred and monitor the scaling.

Challenge

It is rare to have an existing flowmeter with supply and return temperature sensors. At the same time, it is highly preferable to avoid downtime that could be created by the installation and maintenance of a solution, without impacting the operation of the heat exchanger. A fit for purpose solution is available.

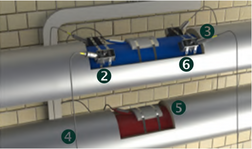

Panametrics’ liquid clamp-on flowmeters, DigitalFlow DF868 with temperature inputs, are perfectly suited for live monitoring energy efficiency data of the heat exchangers available in BTU/h or kcal/h. The solution calculates the gained and given Energy (∆ BTU /h) for each of the two fluids used on the heat exchanger. This enables the customer to compare exchanged energy with target / design value and defined current efficiency, and therefore provides early alerts for any decline in efficiency.

In addition, Panametrics’ technology will monitor the flow rate / flow velocity. This gives the customer an early alert of the presence of scaling on heat exchanger tubes, which in turn will reduce risk for leakage.

As a clamp-on solution, Panametrics’ flowmeters are easy to install on any pipe with no need for downtime. Panametrics’ clamp on temperature transmitters can also be connected to the meter electronics or wetted using thermowells for better accuracy of the temperature measurement, if required.

Panametrics’ ultrasonic clamp on flow meter solutions are widely used across heat exchanger operations, providing customers with accurate and reliable measurements, leading to improved efficiency, productivity and reduced costs.

Benefits

- Easy to set up

- Easy to operate

- No process shutdown required, no downtime

- Energy calculation

Technology used:

Find out more about Panametrics solutions

📍 PT878GC Clamp-On Ultrasonic Flowmeter | Datasheet

💻 Panametrics Flow Meter Solutions