Electrolysis for hydrogen production

Hydrogen is one of the fastest growing market segments today. It is one of the key solutions in achieving a net zero emissions economy by 2050. Hydrogen is being used to replace traditional fossil fuels in many applications, for example: fuel for heavy vehicles; a substitute for natural gas to provide heating; and as a means of storing energy.

Panametrics can play right across the hydrogen value chain, from production and transportation to utilization.

Today the majority of hydrogen is produced from natural gas in a process called steam methane reforming. This is an energy intensive process and a significant contributor to global emissions.

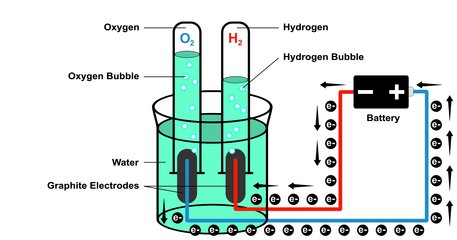

A second way to produce hydrogen is to separate water into its constituent parts of hydrogen and oxygen, through a process called electrolysis. If the electrolysis process is powered by renewable energy like solar or wind, you have completely emissions free hydrogen, or “Green Hydrogen”. Both the steam methane reforming and electrolysis processes need sensors to determine the quality of the hydrogen they are producing.

This is where Panametrics comes in to play. With our sensor technologies, we measure the hydrogen purity and also impurities in the hydrogen such as moisture and oxygen. Reach our team of experts to learn different technology options for the different measurements required, including thermal conductivity for hydrogen purity, electrochemical fuel cell for oxygen, aluminum oxide and laser for moisture.

Moisture, Oxygen, and Hydrogen Sensor Solutions for original equipment manufacturers (OEM’s)

Click here to download Water Electrolysis for Hydrogen Production - Application Note

While the term “the hydrogen economy” is talked about a lot right now, the reality is we have been providing measurements across the hydrogen value chain for many years.

Panametrics have been the go-to analyzer supplier of choice for many gas manufacturers on their steam methane reformer units over many years. We have long historical working relationships with electrolyzer manufacturers globally, providing products and after sales and service support for their electrolysis machines.

Features:

- Intrinsically safe

- Ambient to ppb-level moisture measurement using next-generation aluminum oxide moisture sensor

- Built-in temperature sensor for temperature compensation

- Optional pressure sensor

- Calibrations traceable to National Institute of Standards and Technology (NIST) or National Physical Laboratory (NPL) with the option of fully accredited calibration to ISO 17025

- Complete programming capability via User Interface that consists of integrated display and 6-button keypad

- Analog and digital outputs

- HART communication over the 4 – 20 mA analog output

Features

- Measurement range-90°C to 10°C dew point, 0 to 10 ppmv, 0 to 1000 ppmv (fully adjustable with optional integral

- display)

- Loop-powered, 4 to 20 mA transmitter

- Integ ral filtering and flow regulation (MMY30)

- Standard operating pressure 0 to 120 bar (MMY31), 0 to 31 bar (MMY30)

- Power Supply 24 VDC nominal, 12 to 30 VDC

- Weight 1.5 kg (MMY31) 2 kg (MMY30)

- Trouble-free indoor or outdoor mounting

- Microcontroller electronics in Type 4X/IP67 enclosure

- Integrated display with user interface

Features

- Extremely stable, glass-coated thermistors

- One or two point calibration using a button

- PC interfaces for digital output

- Weather and/or explosion proof version

- EX version ATEX/IECEX II 2 G Exd IIC T6 Gb C-US Class I Div. 1 Groups A, B, C & D

- Analog output 4-20 mA, isolated, 800 Ω max., programmable in the field

- Power supply 24 VDC ± 2 VDC, max. 1.2 A

- Dimensions

- Weatherproof housing (H x D): 242 mm x 145 mm

- Ex-proof housing (H x D): 266 mm x 145 mm

- Weight 4.3 kg

- Protection class IP66/Type 4X

- Standard ranges

0% to 2% 0% to 100%

0% to 5% 50% to 100%

0% to 10% 80% to 100%

0% to 25% 90% to 100%

0% to 50%

Features

- 4-20mA, two-wire, loop powered

- Display with keypad

- Intrinsic safe option Class I, Div 1, Groups ABCD, T4 ATEX/IECEX Ex ia IIC Ga T4

- Proven O2 sensor technology

- User-programmable

- Intuitive user interface with diagnosis function

- Microprocessor based technology

- Low maintenance, economical, compact

- Sensor failure output alarm

- Display of the sensor lifetime

- Error display according to Namur

- Standard O2 Ranges

PPM O2: Percent O2:

0 to 10 ppmv 0% to 1%

0 to 20 ppmv 0% to 2%

0 to 100 ppmv 0% to 5%

0 to 200 ppmv 0% to 10%

0 to 500 ppmv 0% to 25%

0 to 1000 ppmv 0% to 50%

0 to 2000 ppmv

0 to 5000 ppmv

0 to 10.000 ppmv

Resources

| Type | Name | Language | |

|---|---|---|---|

| Brochure |

Electrolysis for hydrogen production Brochure

|

English | |

| Brochure |

Electrolysis for hydrogen production Brochure Chinese

|

Chinese | |

| Brochure |

Electrolysis for hydrogen production Brochure German

|

German | |

| Brochure |

Electrolysis for hydrogen production Brochure Italian

|

Italian | |