Measurement for enhanced performance

Moisture, Oxygen, and Hydrogen Sensor Solutions for OEM Applications:

Moisture and oxygen can naturally occur or leak into any process, and can be problematic if not controlled within an appropriate range. In industrial drying applications, you and your customers want the assurance that the dryer is properly changing towers on demand. In inert environments, the moisture and oxygen readings indicate when your customer can start their work. Original Equipment Manufacturers (OEM’s) strive to measure gas and moisture in order to control contamination from these elements because they can damage the process, equipment and end product by:

- Negatively impacting test results

- Leading to ice formation in cold temperatures

- Causing equipment failure with wear and breakdown

- Reacting with other chemicals and or gases

Electrolyzer by-products include water vapor and oxygen. Precise measurements of hydrogen, oxygen and moisture content can provide an index of the efficiency of the electrolyzer. Maximizing an electrolyzer’s safety and efficiency requires highly reliable and accurate sensor technology.

Featured

Panametrics' smart sensor technologies can optimize your biogas upgrading processes. Learn how our experts can ensure your Renewable Natural Gas is ready for combustion or entry into the grid.

Featured

When glove box processes require a protective atmosphere, the volume is purged with dry, inert gas such as nitrogen, argon or helium. This micro-environment requires monitoring and control.

Featured

Metal parts, alloys and sheet steel are processed in furnaces at elevated

temperatures. Controlled atmospheres are used to infuse desired properties and

in pretreatment for depositing coatings. Hydrogen concentrations in the furnace

atmosphere must be precisely controlled to optimize the finished product yield

and quality.

Featured

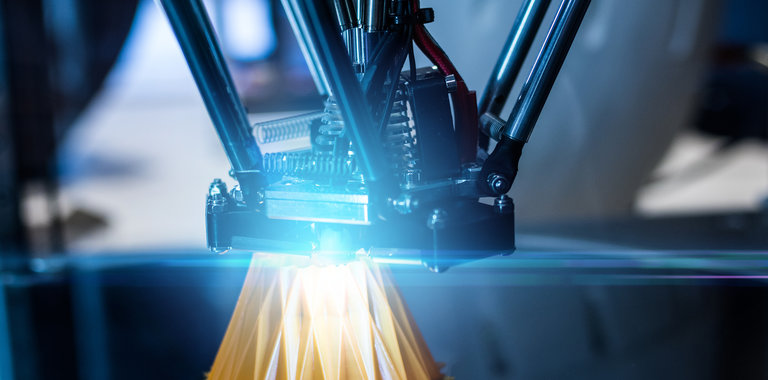

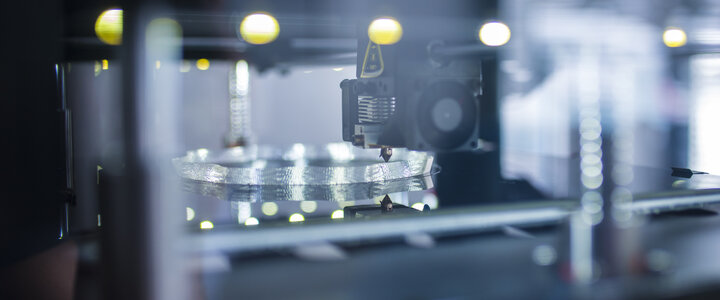

3D printing is expected to show significant growth in the coming years. The process of 3D printing involves applying layers of fine dust metals or polymers and then fusing the layers with laser technology. The process takes place in the chamber of the 3D printing machine where the environment is closely monitored for oxygen and moisture content.

Featured

Instrument or utility air is widely used in manufacturing settings to operate various types of pneumatic equipment, valves, and electrical controls. If instrument air contains too much moisture, it can lead to downtime and maintenance costs.

Featured

Panametrics OEM's solutions

Need Help?

In need of support? Contact a Panametrics expert via email or phone for immediate assistance.